As a key oil and gas producer in Central Asia, Kazakhstan’s oilfields are characterized by a large number of wells, wide geographical distribution (with distances between wells in a single block reaching several kilometers), complex geological conditions, and diverse equipment types. A major oilfield enterprise faced significant challenges in its operations: the traditional manual inspection model was inefficient, requiring substantial manpower to monitor scattered wells; real-time visibility of the operational status of thousands of pumping units was lacking; delayed fault response led to severe downtime losses; operational and maintenance (O&M) costs remained high; and energy consumption management lacked precise data support.

To address these pain points, the enterprise partnered with WideIOT to build a smart oilfield solution based on IoT technology, achieving full-lifecycle intelligent management of oil wells.

Project Challenges

The digital transformation of Kazakhstan’s oilfields encountered hurdles in multi-protocol compatibility and remote O&M:

- Complex protocol heterogeneity: On-site oilfield equipment uses multiple industrial protocols, including ModbusTCP, OPC UA, and IEC 104 for some devices.

- High requirements for data transmission stability: Most oilfields are located in remote areas with complex network environments. Critical data such as motor current, voltage, dynamometer cards, and stroke frequency must be uploaded to the cloud in real time with strict latency control.

- Stringent security for remote control: Remote operations (e.g., starting/stopping pumping units, adjusting stroke frequency) directly impact production safety. Encrypted transmission and hierarchical permission mechanisms are essential to avoid misoperation risks.

- Insufficient intelligent condition diagnosis: Traditional manual analysis of dynamometer card data struggled to quickly identify downhole faults (e.g., insufficient fluid supply, gas interference, sucker rod breakage), resulting in low early warning accuracy.

Solution

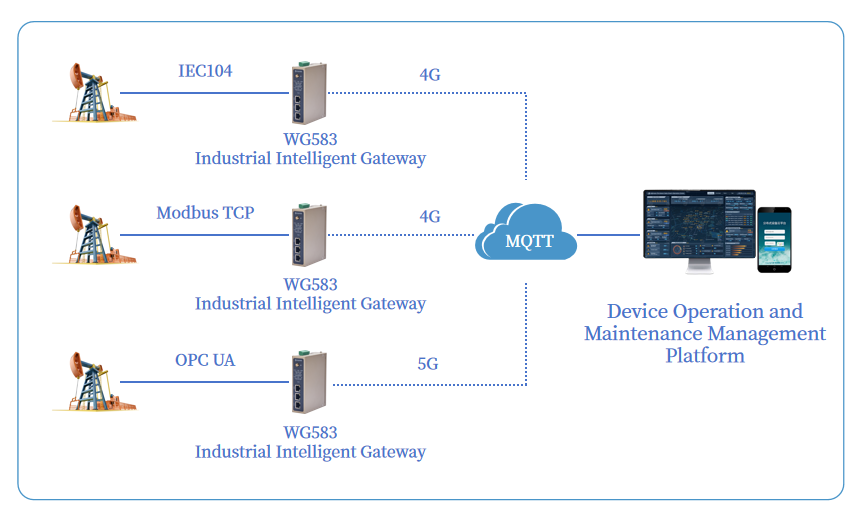

Targeting the customer’s core needs in protocol compatibility, intelligent O&M, and data security, WideIOT built an end-to-end intelligent monitoring and management system centered on the

WG583 Industrial Intelligent Gateway, paired with a

Device Operation and Maintenance Management Platform. This system enables a smart management upgrade featuring "full perception, remote controllability, and precise optimization."

WG583 Industrial Intelligent Gateway – The "Hub" for Protocol Compatibility and Reliable Transmission

Powerful Protocol Adaptation and Data Acquisition

The WG583 boasts robust protocol parsing capabilities, supporting simultaneous compatibility with IEC 104, ModbusTCP, OPC UA, and other protocols. It enables real-time collection of operational parameters from various types of pumping units, including motor current/voltage, dynamometer cards, stroke frequency, oil production, wellhead pressure, and temperature.

Stable Data Processing and Transmission

The gateway supports edge-side data preprocessing, filtering invalid data and standardizing formats. It then transmits data to the smart oilfield management platform via 5G/4G networks using the lightweight MQTT IoT protocol. Equipped with multi-network redundancy, disconnection reconnection, breakpoint resume, and secure encryption, it ensures the safe and complete transmission of data.

Industrial-Grade Design for Harsh Environments

The WG583 features an industrial-grade hardware design with built-in dual software and hardware watchdogs for automatic recovery from abnormal conditions. It offers electromagnetic interference (EMI) resistance to withstand complex electromagnetic environments on-site. With an IP30 protection rating, an operating temperature range of -20℃~70℃, and a wide voltage power supply (6V-35V), it perfectly adapts to harsh oilfield conditions such as extreme temperatures and voltage fluctuations.

Device Operation and Maintenance Management Platform – End-to-End Empowerment from "Remote Visibility" to "Intelligent Decision-Making"

Remote Monitoring: "Full Visibility on One Screen" in the Central Control Room

A visual dashboard displays the oilfield well distribution map. Managers in the central control room can real-time monitor the distribution, operational status, and critical parameters (e.g., motor current/voltage, dynamometer cards, stroke frequency, wellhead pressure/temperature) of all wells in a visualized manner.

Alarm and Early Warning: Accurate Fault Judgment and Proactive Troubleshooting

Managers can set custom alarm rules on the platform. When parameters exceed preset thresholds, the platform automatically notifies managers via WeChat, SMS, or email, enabling real-time detection and timely troubleshooting of abnormalities. This reduces unplanned downtime and frees on-site O&M personnel from the inefficient "well-hopping inspection" model.

Remote Control: Safe and Efficient Remote Operations

The platform implements a strict hierarchical permission management mechanism, with different roles assigned distinct operational scopes. O&M personnel can perform emergency remote shutdowns to significantly reduce safety risks.

- Start/Stop Control: Managers can one-click start/stop individual well pumping units (e.g., temporary shutdown of low-yield wells at night for energy savings) or conduct batch operations for wells in the same block.

- Parameter Optimization: Based on real-time data (e.g., insufficient fluid supply indicated by dynamometer cards), dynamically adjust the pumping unit’s stroke frequency (e.g., reduce to 3 strokes per minute to minimize empty pumping energy consumption) or modify the inverter frequency via ModbusTCP to adjust motor speed, avoiding equipment overload or inefficient operation.

Data Analysis and Optimization: Driving Data-Driven Production Decisions

Managers use the platform to analyze real-time, historical, and dynamometer card data to assess pump performance (e.g., insufficient fluid supply, gas interference, sucker rod breakage). This supports scientific decision-making for fault early warning, energy conservation, and efficiency improvement, continuously optimizing production plans and enhancing operational efficiency and economic benefits.

Project Achievements

1. Significantly Improved O&M Efficiency

The solution enables "managing thousands of wells on one screen," upgrading the traditional manual inspection model to "online monitoring + offline precise maintenance." The manpower requirement for inspections in a single block has been reduced by over 60%, drastically cutting manual inspection costs. Fault response time has been shortened, and the timely handling rate of downhole faults has reached 95%, effectively reducing unplanned downtime caused by malfunctions.

2. Sustained Optimization of Energy Consumption Costs

Dynamic adjustment of stroke frequency and inverter frequency has reduced the average daily power consumption per well by 12%-18%. Additionally, the platform’s precise analysis of equipment energy consumption data provides support for formulating energy consumption quotas and energy-saving renovations, driving an overall 8% reduction in energy consumption.

3. Effective Prevention and Control of Safety Risks

Intelligent alarms and emergency shutdown functions have responded quickly to multiple abnormal equipment conditions, avoiding pumping unit overload damage and wellhead safety accidents. Unplanned downtime losses have been reduced by 40%, the safe operation cycle of equipment has been extended by 30%, and production stability has been significantly enhanced.

4. Substantial Reduction in O&M Costs

Breaking away from the traditional reactive maintenance model, the oilfield has shifted to "proactive early warning and predictive maintenance." Equipment failure rates have decreased by 25%, and maintenance costs have been cut by 18%.

5. Comprehensive Upgrade of Management Models

The project has built a "data-driven production" smart management system, realizing full-process digital control of oil wells from extraction and O&M to optimization. Managers can obtain real-time multi-dimensional data reports (e.g., production volume, energy consumption, equipment status) via the platform, shifting production decisions from "experience-based judgment" to "data-supported decision-making" and improving management efficiency by 40%.

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.View details>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.View details> WideIOT focuses on common aspects in factories such as production line IoT and data collection, equipment operation management, energy consumption analysis and control, production safety monitoring, and environmental protection monitoring. Through the application of advanced technologies like the Internet of Things (IoT) and big data, it provides enterprises with one-stop digital solutions for smart factories, including equipment networking, data collection, data standardization, data monitoring, and data application. These solutions improve the digitalization and intelligentization level of factories, promoting the transformation, upgrading, and sustainable development of manufacturing enterprises.View details>Production Line IoT & Data CollectionEquipment Operation ManagementEnergy Consumption Analysis & ControlProduction Safety MonitoringFactory Environmental Protection MonitoringEquipment Network Isolation

WideIOT focuses on common aspects in factories such as production line IoT and data collection, equipment operation management, energy consumption analysis and control, production safety monitoring, and environmental protection monitoring. Through the application of advanced technologies like the Internet of Things (IoT) and big data, it provides enterprises with one-stop digital solutions for smart factories, including equipment networking, data collection, data standardization, data monitoring, and data application. These solutions improve the digitalization and intelligentization level of factories, promoting the transformation, upgrading, and sustainable development of manufacturing enterprises.View details>Production Line IoT & Data CollectionEquipment Operation ManagementEnergy Consumption Analysis & ControlProduction Safety MonitoringFactory Environmental Protection MonitoringEquipment Network Isolation WideIOT focuses on common factory needs such as production line IoT integration and data acquisition, equipment operation management, energy consumption analysis and control, production safety monitoring, and environmental monitoring. By leveraging advanced technologies like IoT and big data, we provide enterprises with one-stop smart factory solutions encompassing equipment networking, data collection, data standardization, data monitoring, and data application. We elevate factories' digitalization and intelligence levels, driving the transformation, upgrading, and sustainable development of manufacturing enterprises!View details>

WideIOT focuses on common factory needs such as production line IoT integration and data acquisition, equipment operation management, energy consumption analysis and control, production safety monitoring, and environmental monitoring. By leveraging advanced technologies like IoT and big data, we provide enterprises with one-stop smart factory solutions encompassing equipment networking, data collection, data standardization, data monitoring, and data application. We elevate factories' digitalization and intelligence levels, driving the transformation, upgrading, and sustainable development of manufacturing enterprises!View details> WideIOT, founded in 2011, is a professional provider of industrial Internet of Things products and industrial digital solutions. WideIOT focuses on providing industrial intelligent gateway, industrial data acquisition terminal, equipment remote maintenance management system, industrial equipment data cloud platform and other products and solutions for equipment manufacturers, intelligent factories, industrial projects and other fields, to help customers achieve digital operation management and industrial Internet new value mining. WideIOT's products are widely used in intelligent factories, equipment manufacturers, environmental protection industry, energy industry, municipal engineering, industrial automation, smart agriculture, building intelligence and other industrial fields.View details>50+Countries500+Clients1M+Devices

WideIOT, founded in 2011, is a professional provider of industrial Internet of Things products and industrial digital solutions. WideIOT focuses on providing industrial intelligent gateway, industrial data acquisition terminal, equipment remote maintenance management system, industrial equipment data cloud platform and other products and solutions for equipment manufacturers, intelligent factories, industrial projects and other fields, to help customers achieve digital operation management and industrial Internet new value mining. WideIOT's products are widely used in intelligent factories, equipment manufacturers, environmental protection industry, energy industry, municipal engineering, industrial automation, smart agriculture, building intelligence and other industrial fields.View details>50+Countries500+Clients1M+Devices