Data Collection

Remote Monitoring

Abnormal Alarm

Operation and Maintenance Management

Remote Maintenance

Data Analysis

Home

Product

Industries

Solution

About Us

Service Support

Contact Us

Data Collection

Remote Monitoring

Abnormal Alarm

Operation and Maintenance Management

Remote Maintenance

Data Analysis

Switch

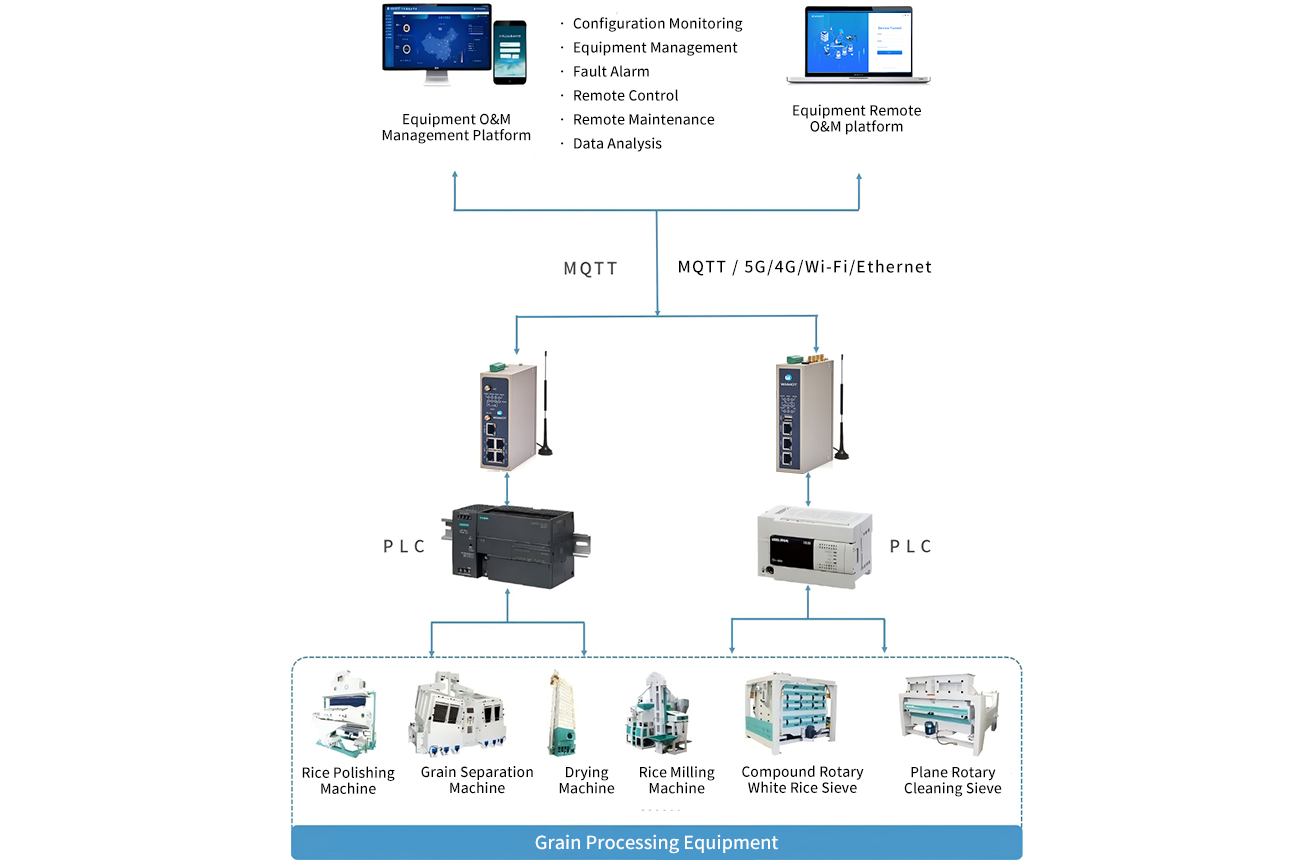

WideIOT provides a smart operation and maintenance system solution for remote monitoring of grain processing equipment based on industrial smart gateways. By connecting the PLC controllers of destoners, rice hullers, polishers, and dryers to WideIOT's industrial smart gateways, the gateways collect equipment data and transmit it via 5G/4G networks to the equipment operation and maintenance management platform. This enables monitoring and management of equipment location distribution, quantity and type, operational status, alarm events, and maintenance work orders. By comprehensively applying big data analytics, it drives enterprise operational decision-making and service upgrades, effectively strengthens aftermarket development, and enhances market competitiveness.

Collect PLC data of grain and oil machinery and equipment through gateways. The gateway is compatible with multiple PLC protocols and supports connection to cloud platforms or upper computers via 5G/4G/WIFI/Ethernet and other methods.

Through mobile phones, computers or enterprise large screens, you can monitor information such as the location, model, status and parameters of each device. You can also quickly query data such as the associated customer, purchase time and fault frequency for configuration and operation.

By setting intelligent alarm rules, notifications will be sent when abnormal data is collected. Managers will be informed via WeChat, SMS, email and other methods to facilitate quick location, diagnosis and reasonable control.

Realize the creation, editing, management, assignment, review and other operations of electronic O&M work orders. Query work order logs, processing time, maintenance progress, etc. anytime and anywhere, forming a closed-loop information-based working mechanism covering the entire process.

With the help of WideIOT Equipment Maintenance Channel, engineers can perform remote programming, debugging and remote program upload/download operations on off-site PLCs. Program maintenance can be carried out without business trips, achieving greater cost reduction and efficiency improvement.

Through information such as fault frequency and maintenance logs of different equipment, equipment manufacturers can identify equipment defects and obtain more efficient maintenance plans. This provides decision support for equipment upgrades, new product R&D or after-sales service enhancement.