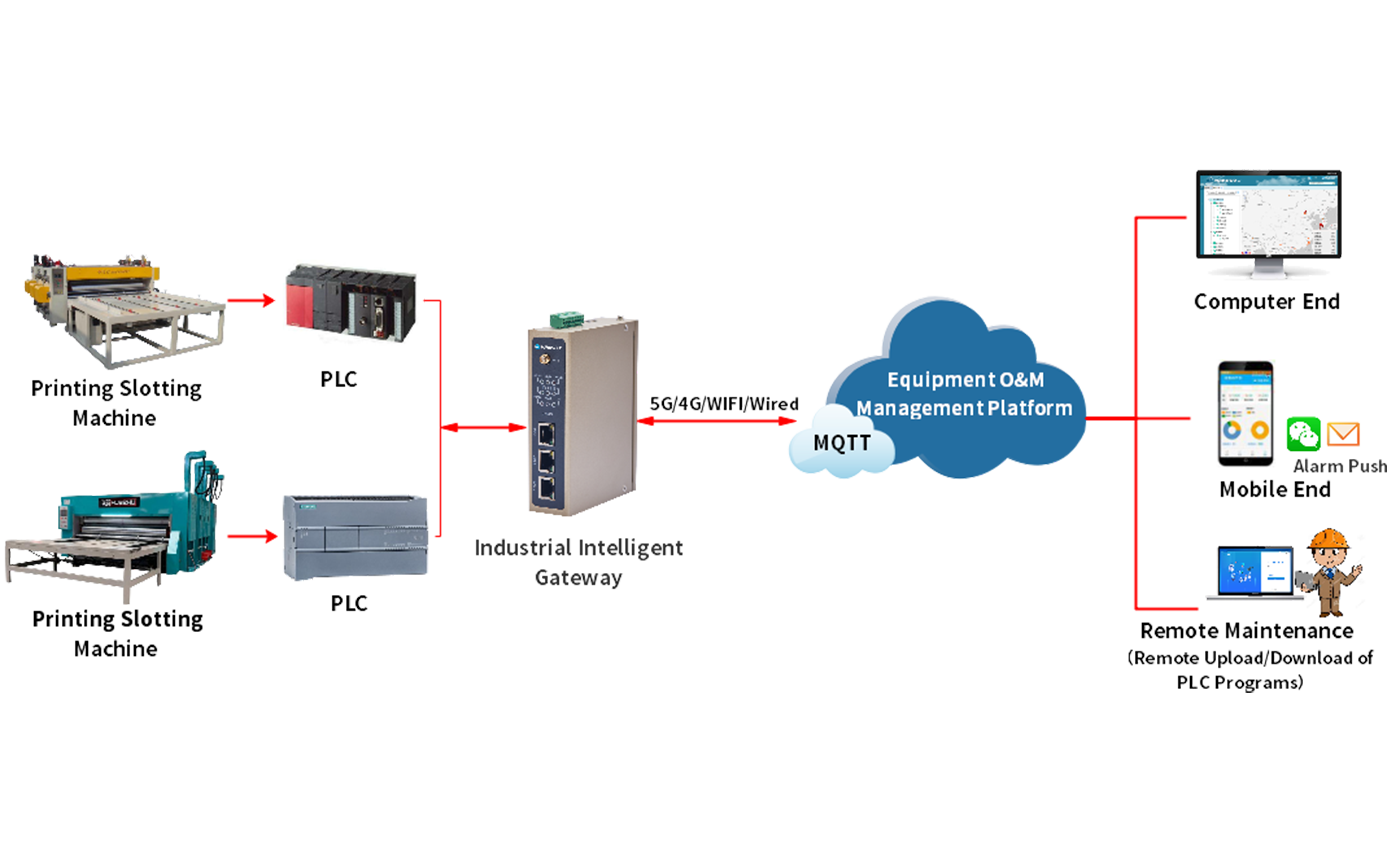

WideIOT uses its WG series industrial intelligent gateways as the link between equipment and monitoring systems, enabling remote monitoring and maintenance of printing machinery data and delivering intelligent operation and maintenance solutions for printing enterprises. Boasting rich interfaces and communication protocols to match printing equipment’s complexity and diversity, these gateways connect to core controllers (e.g., PLCs) to collect real-time operational data like status, temperature, pressure and vibration. Via 5G, 4G, WIFI or wired Ethernet, data is uploaded to a cloud platform, building a remote monitoring system that enhances equipment management, enables full, timely and accurate operational oversight, and integrates production status with processes. Configurable early warning thresholds support fault pre-alerts and diagnosis, with instant notifications for anomalies. Technicians can perform remote troubleshooting and maintenance via a dedicated fast channel, boosting O&M efficiency and cutting related costs significantly.