Energy Data Collection

Energy Consumption Analysis

Energy Usage Strategy Optimization

Energy Cost Accounting

Energy Performance Evaluation

Energy Early Warning and Control

Home

Product

Industries

Solution

About Us

Service Support

Contact Us

Energy Data Collection

Energy Consumption Analysis

Energy Usage Strategy Optimization

Energy Cost Accounting

Energy Performance Evaluation

Energy Early Warning and Control

Switch

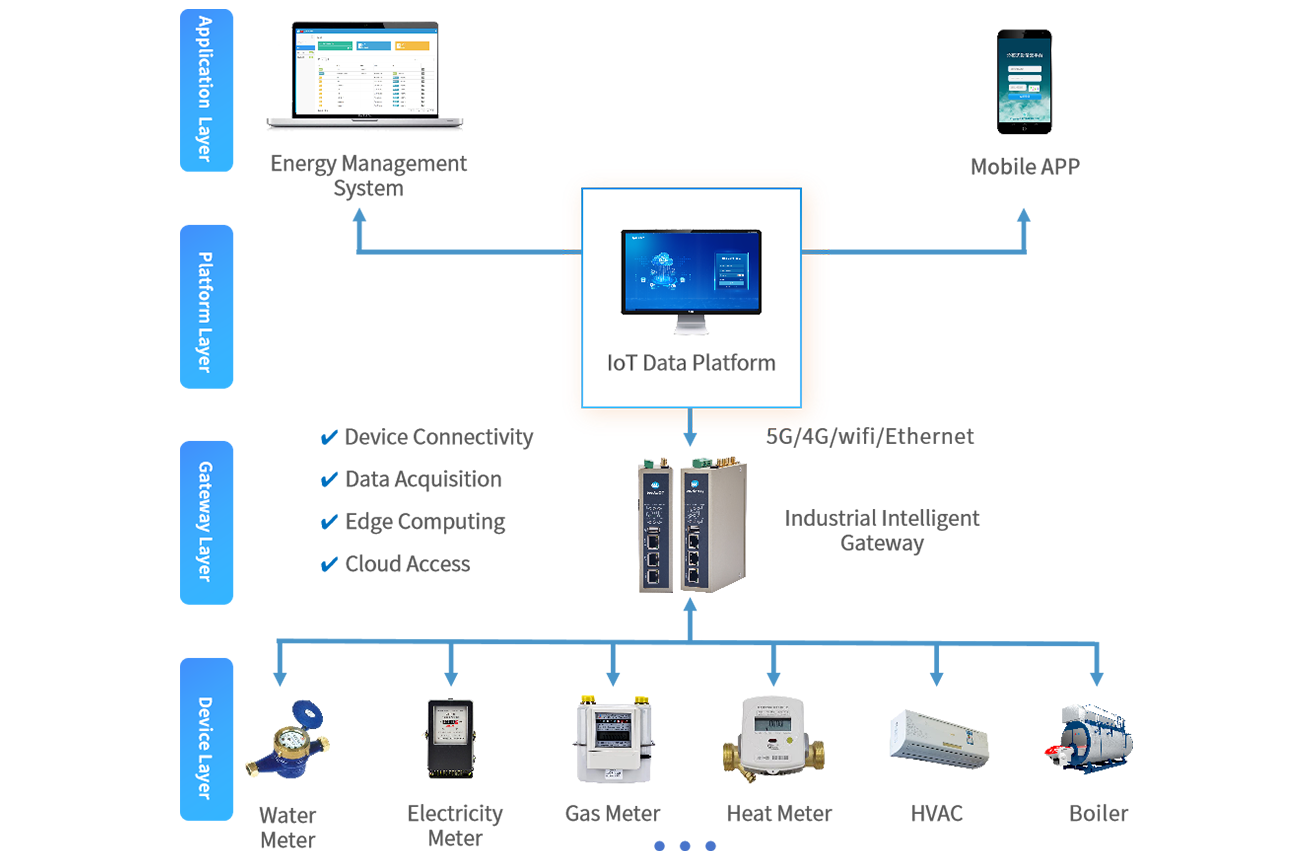

WideIOT Factory Energy Management Solution collects data from factory energy-consuming equipment to provide real-time monitoring of energy usage, alarms, and other conditions at various points in the factory. It helps factories establish an efficient energy consumption monitoring and management system to comprehensively manage energy data, timely identify and resolve energy waste issues. The solution enables peak load shifting for factories, improves energy utilization efficiency, and reduces enterprise operating costs. By mining data value, it provides data support for enterprises' energy-saving decisions and operational decisions.

Through functions such as data visualization and remote monitoring, it enables real-time grasp of factory energy consumption and improves management flexibility and efficiency.

Conduct in-depth analysis of energy consumption structure and trends, research energy conversion efficiency and energy efficiency improvement plans, explore energy-saving potential, and reduce energy consumption.

Implement intelligent analysis, intelligent diagnosis, and real-time energy-saving optimization. Construct targeted and operable energy-saving countermeasures and establish scientific energy-saving plans to achieve energy conservation and consumption reduction.

Accurately calculate energy costs to provide a basis for cost control, ensuring enterprises set reasonable energy-saving and carbon reduction goals at appropriate stages.

By analyzing energy consumption data of various equipment, production lines, workshops, and teams, it provides data support for operational decisions and financing decisions.

Real-time monitor power quality issues, timely detect abnormal energy consumption, and prevent energy waste through control measures.