Real-time Data Collection

Equipment Status Monitoring

Combustion Condition Optimization

Pollutant Emission Monitoring

Fault Early Warning and Handling

Remote Operation and Maintenance Management

Home

Product

Industries

Solution

About Us

Service Support

Contact Us

Real-time Data Collection

Equipment Status Monitoring

Combustion Condition Optimization

Pollutant Emission Monitoring

Fault Early Warning and Handling

Remote Operation and Maintenance Management

Switch

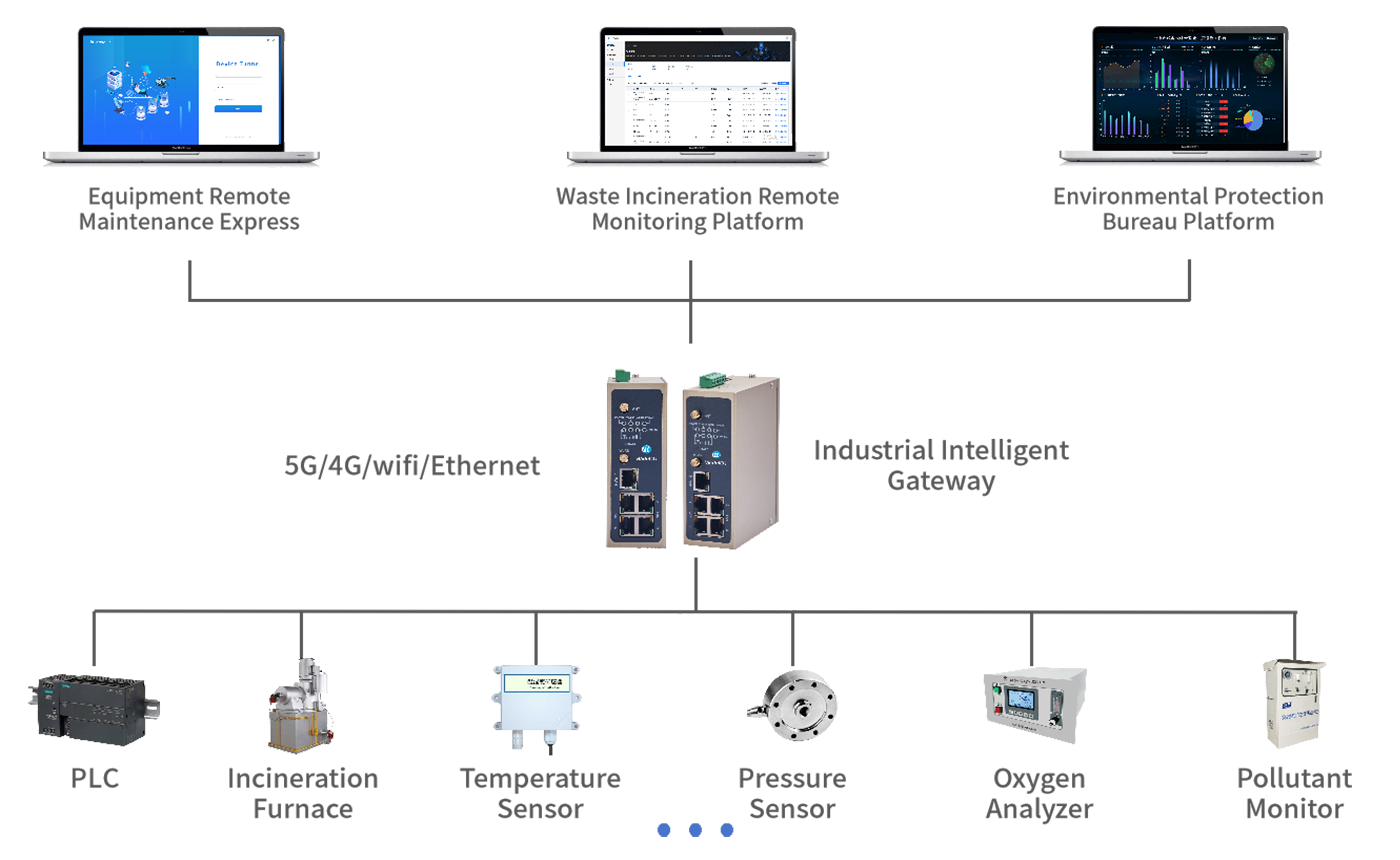

Various sensors and monitoring devices are installed at garbage incineration plants. Via WideIOT's industrial intelligent gateways, operational data of incinerators (such as temperature, pressure, and oxygen content), combustion condition data, and pollutant emission data (such as sulfur dioxide, nitrogen oxides, and particulate matter) are collected.

The collected data is transmitted to the remote monitoring system for garbage incineration treatment, where the platform performs real-time analysis and processing of the data. It optimizes the incineration process based on combustion condition data; when equipment malfunctions or pollutant emissions exceed standards, the platform issues timely early warnings and provides fault diagnosis and handling recommendations. Additionally, it supports remote operation and maintenance operations, such as adjusting incinerator parameters and starting/stopping auxiliary equipment.

Acquire comprehensive and accurate incineration data to provide a basis for optimization and control.

Real-time grasp of equipment operation status, prevent equipment faults in advance, and ensure the continuous and stable incineration process.

Adjust the incineration process according to data to improve combustion efficiency and reduce energy consumption.

Real-time monitor pollutant emission to ensure up-to-standard discharge and reduce environmental pollution.

Timely detect potential faults, handle faults quickly, and reduce downtime and losses.

Realize remote operation and maintenance to improve operation and maintenance efficiency and reduce operation and maintenance costs.