-

Home

-

Product

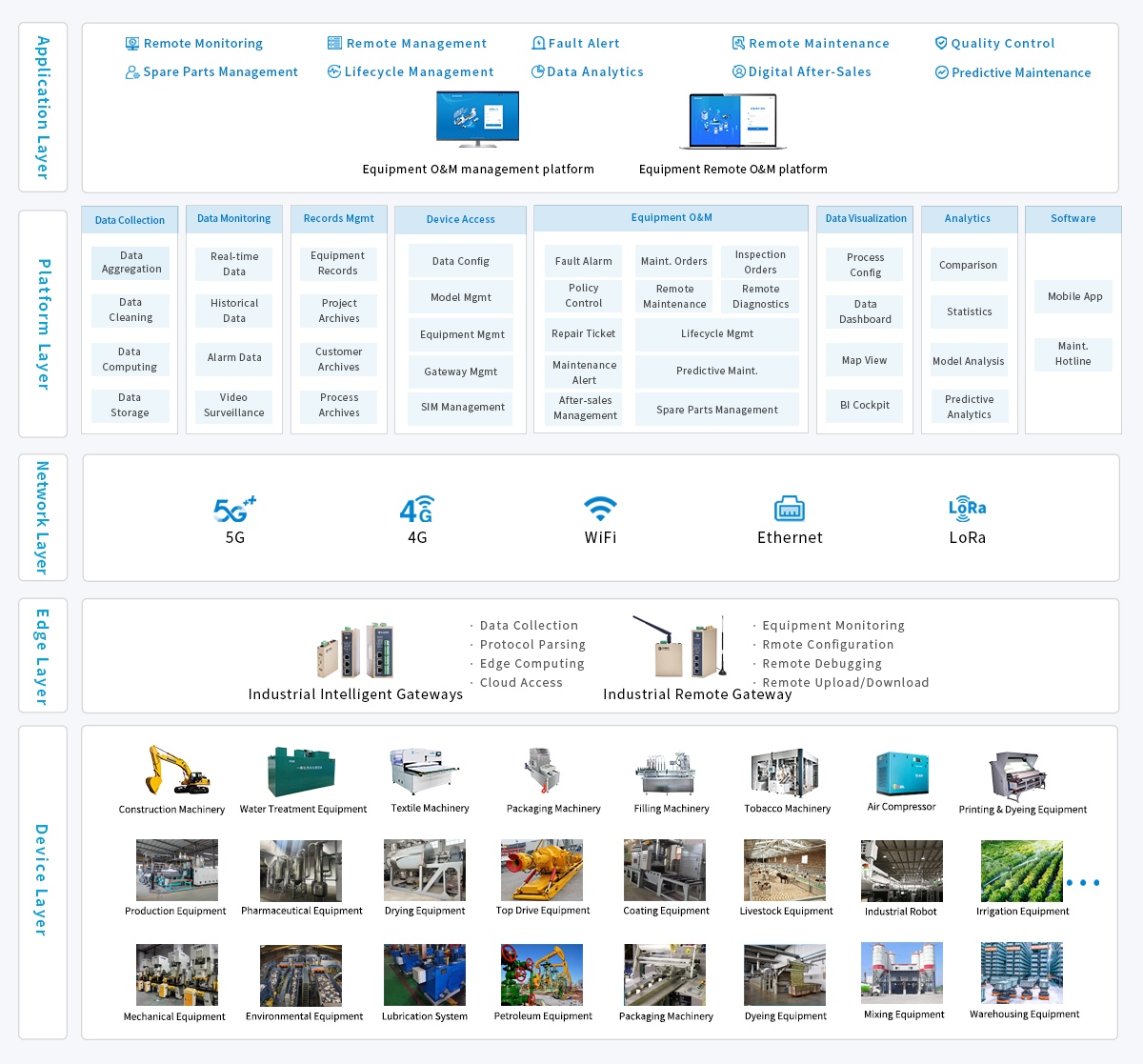

ProductIndustrial GateWay IOT Terminals Industrial Router NAT Coupler IOT Data Platform Equipment Remote Maintenance System Equipment Remote Access Platform WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.View details>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.View details> WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.View details>Digital DI, DOtransparent transmissionModbus RTUAnalog AI, AOLORA transmission4G to the cloud

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.View details>Digital DI, DOtransparent transmissionModbus RTUAnalog AI, AOLORA transmission4G to the cloud WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.View details>5G/4G networkingWiFi networkingVPN networkingReconnect after disconnectionRemote managementHigh safety and reliability

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.View details>5G/4G networkingWiFi networkingVPN networkingReconnect after disconnectionRemote managementHigh safety and reliability The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.View details>IP Address TranslationCross-Segment AccessNetwork Isolation ProtectionVPN NetworkingNAT TranslationIndustrial Design

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.View details>IP Address TranslationCross-Segment AccessNetwork Isolation ProtectionVPN NetworkingNAT TranslationIndustrial Design WideIOT·The IOT Data Platform( industrial equipment data platform )is a highly concurrent cloud platform for remote management and visualization of industrial equipment data, which is widely used in intelligent factory data acquisition middle platform, remote equipment operation management platform, Internet of Things data cloud platform in various industries, etc.View details>Equipment accessEfficient data collectionConfiguration ControlData analysisPreventive maintenanceAPI interface

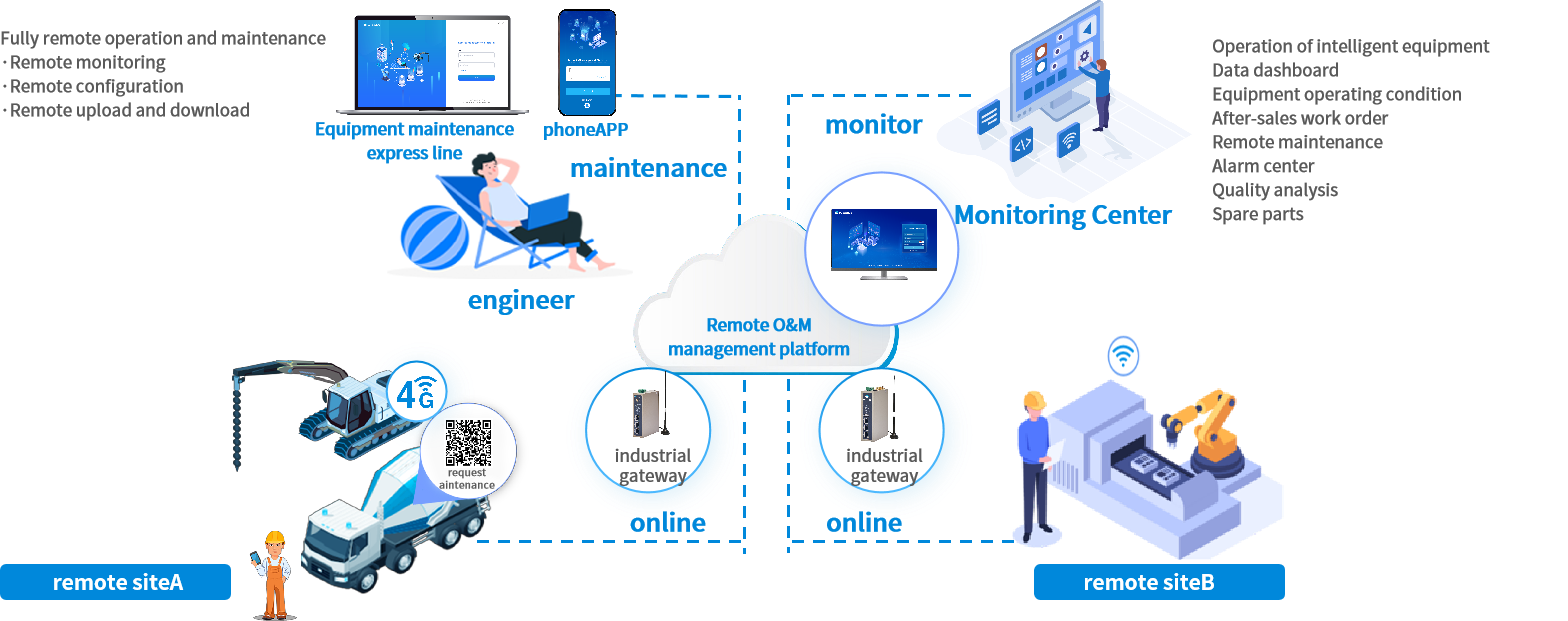

WideIOT·The IOT Data Platform( industrial equipment data platform )is a highly concurrent cloud platform for remote management and visualization of industrial equipment data, which is widely used in intelligent factory data acquisition middle platform, remote equipment operation management platform, Internet of Things data cloud platform in various industries, etc.View details>Equipment accessEfficient data collectionConfiguration ControlData analysisPreventive maintenanceAPI interface WideIOT Equipment Remote Maintenance System is a software and hardware system that realizes remote maintenance and operation of distributed equipment. Configuration, remote diagnostics, remote debugging and remote upgrade procedures.View details>Remote configurationRemote debuggingRemote upload and downloadRemote maintenanceRemote monitoringPreventive maintenance

WideIOT Equipment Remote Maintenance System is a software and hardware system that realizes remote maintenance and operation of distributed equipment. Configuration, remote diagnostics, remote debugging and remote upgrade procedures.View details>Remote configurationRemote debuggingRemote upload and downloadRemote maintenanceRemote monitoringPreventive maintenance WideIOT·The equipment remote access cloud platform is a fast access platform for real-time monitoring of distributed equipment data, which adopts SAAS cloud service mode to establish real-time online data channels for the interconnection of various industrial equipment data at the industrial site.View details>Project monitoringDevice interconnectionNo public IP requiredFast and low cost accessLive online channelPeer-to-peer communication

WideIOT·The equipment remote access cloud platform is a fast access platform for real-time monitoring of distributed equipment data, which adopts SAAS cloud service mode to establish real-time online data channels for the interconnection of various industrial equipment data at the industrial site.View details>Project monitoringDevice interconnectionNo public IP requiredFast and low cost accessLive online channelPeer-to-peer communication -

Industries

IndustriesFactory Digitalization Equipment Digitalization Energy Digitalization Vehicle Digitalization Smart Water Conservancy Smart Agri-Husbandry Smart City WideIOT focuses on common aspects in factories such as production line IoT and data collection, equipment operation management, energy consumption analysis and control, production safety monitoring, and environmental protection monitoring. Through the application of advanced technologies like the Internet of Things (IoT) and big data, it provides enterprises with one-stop digital solutions for smart factories, including equipment networking, data collection, data standardization, data monitoring, and data application. These solutions improve the digitalization and intelligentization level of factories, promoting the transformation, upgrading, and sustainable development of manufacturing enterprises.View details>Production Line IoT & Data CollectionEquipment Operation ManagementEnergy Consumption Analysis & ControlProduction Safety MonitoringFactory Environmental Protection MonitoringEquipment Network Isolation

WideIOT focuses on common aspects in factories such as production line IoT and data collection, equipment operation management, energy consumption analysis and control, production safety monitoring, and environmental protection monitoring. Through the application of advanced technologies like the Internet of Things (IoT) and big data, it provides enterprises with one-stop digital solutions for smart factories, including equipment networking, data collection, data standardization, data monitoring, and data application. These solutions improve the digitalization and intelligentization level of factories, promoting the transformation, upgrading, and sustainable development of manufacturing enterprises.View details>Production Line IoT & Data CollectionEquipment Operation ManagementEnergy Consumption Analysis & ControlProduction Safety MonitoringFactory Environmental Protection MonitoringEquipment Network Isolation WideIOT provides equipment digitalization solutions for equipment manufacturers. By deeply integrating advanced technologies such as the Internet, IoT, and big data, it covers multiple aspects including equipment data collection, remote monitoring, fault early warning, data analysis, equipment full-lifecycle management, spare parts management, predictive maintenance, and service innovation. It builds a unified intelligent service management platform covering domestic and overseas markets, helping equipment manufacturers achieve intelligent upgrading of equipment, improve management efficiency, reduce operation and maintenance costs, and enhance enterprise service efficiency and quality.View details>Equipment Data CollectionEquipment Remote MonitoringEquipment Fault Early WarningFull-Lifecycle ManagementSpare Parts ManagementPredictive Maintenance

WideIOT provides equipment digitalization solutions for equipment manufacturers. By deeply integrating advanced technologies such as the Internet, IoT, and big data, it covers multiple aspects including equipment data collection, remote monitoring, fault early warning, data analysis, equipment full-lifecycle management, spare parts management, predictive maintenance, and service innovation. It builds a unified intelligent service management platform covering domestic and overseas markets, helping equipment manufacturers achieve intelligent upgrading of equipment, improve management efficiency, reduce operation and maintenance costs, and enhance enterprise service efficiency and quality.View details>Equipment Data CollectionEquipment Remote MonitoringEquipment Fault Early WarningFull-Lifecycle ManagementSpare Parts ManagementPredictive Maintenance WideIOT, based on the characteristics of the energy industry, utilizes advanced technologies such as the Internet of Things, big data, and artificial intelligence. With the collection and analysis of data from various energy sources (including water, electricity, heat, and gas) as its foundation, it provides one-stop energy digital solutions covering energy data collection, equipment supervision, energy consumption monitoring, optimized scheduling, energy-saving analysis, energy control, and safety early warning management. These solutions help energy enterprises improve energy utilization efficiency, reduce operating costs, and drive the digital transformation and green development of the energy industry.View details>Data CollectionEquipment SupervisionEnergy Consumption MonitoringOptimized SchedulingEnergy-Saving AnalysisEnergy Control

WideIOT, based on the characteristics of the energy industry, utilizes advanced technologies such as the Internet of Things, big data, and artificial intelligence. With the collection and analysis of data from various energy sources (including water, electricity, heat, and gas) as its foundation, it provides one-stop energy digital solutions covering energy data collection, equipment supervision, energy consumption monitoring, optimized scheduling, energy-saving analysis, energy control, and safety early warning management. These solutions help energy enterprises improve energy utilization efficiency, reduce operating costs, and drive the digital transformation and green development of the energy industry.View details>Data CollectionEquipment SupervisionEnergy Consumption MonitoringOptimized SchedulingEnergy-Saving AnalysisEnergy Control WideIOT leverages technologies such as big data, IoT, and mobile Internet to realize the collection and transmission of vehicle data and information. It collects and uploads key vehicle information and positioning data to the vehicle management platform in real time for display, monitoring, and analysis. This enables detection of the operating status of vehicle equipment, monitoring of vehicle driving trajectories, and issuance of alerts for abnormal situations—timely identifying vehicle anomalies. It assists operations managers in vehicle management and after-sales maintenance personnel in remotely handling faults, reducing the probability of accidents during vehicle operation. Additionally, it achieves full-lifecycle management of vehicles and integrated vehicle management, operation, and maintenance, helping enterprises improve vehicle operation efficiency, reduce operating costs, and enhance service quality and safety.View details>Vehicle Data AccessVehicle Operation MonitoringVehicle Positioning and DispatchingVehicle Fault AlarmRemote Operation and MaintenanceVehicle Data Analysis

WideIOT leverages technologies such as big data, IoT, and mobile Internet to realize the collection and transmission of vehicle data and information. It collects and uploads key vehicle information and positioning data to the vehicle management platform in real time for display, monitoring, and analysis. This enables detection of the operating status of vehicle equipment, monitoring of vehicle driving trajectories, and issuance of alerts for abnormal situations—timely identifying vehicle anomalies. It assists operations managers in vehicle management and after-sales maintenance personnel in remotely handling faults, reducing the probability of accidents during vehicle operation. Additionally, it achieves full-lifecycle management of vehicles and integrated vehicle management, operation, and maintenance, helping enterprises improve vehicle operation efficiency, reduce operating costs, and enhance service quality and safety.View details>Vehicle Data AccessVehicle Operation MonitoringVehicle Positioning and DispatchingVehicle Fault AlarmRemote Operation and MaintenanceVehicle Data Analysis WideIOT's Smart Water Conservancy Solution builds a global perception network to realize real-time online monitoring, early warning and forecasting of rainfall conditions, water conditions, and project conditions, support remote/intelligent control, and aggregate and analyze data through a unified platform. It empowers refined management and scientific decision-making for core businesses such as flood control scheduling, water resource management, and irrigation area operation and maintenance, comprehensively improving waterlogging and drought disaster prevention capabilities and water resource utilization efficiency.View details>Real-time MonitoringLarge-screen DisplayEarly Warning and AlarmStation ManagementData AnalysisData Sharing

WideIOT's Smart Water Conservancy Solution builds a global perception network to realize real-time online monitoring, early warning and forecasting of rainfall conditions, water conditions, and project conditions, support remote/intelligent control, and aggregate and analyze data through a unified platform. It empowers refined management and scientific decision-making for core businesses such as flood control scheduling, water resource management, and irrigation area operation and maintenance, comprehensively improving waterlogging and drought disaster prevention capabilities and water resource utilization efficiency.View details>Real-time MonitoringLarge-screen DisplayEarly Warning and AlarmStation ManagementData AnalysisData Sharing WideIOT utilizes technologies such as the Internet of Things, sensors, and big data, focusing on all links of agricultural and animal husbandry production (including planting and breeding) to provide smart agriculture solutions like environmental monitoring, precision irrigation, and intelligent breeding. By real-time collecting agricultural and animal husbandry production data, environmental and meteorological data, etc., it helps farmers improve production efficiency, reduce operation and maintenance costs, and enhance the quality and output value of agricultural products.View details>Data AccessEquipment ManagementAlarm and Early WarningRemote Operation and MaintenanceRemote ControlData Analysis

WideIOT utilizes technologies such as the Internet of Things, sensors, and big data, focusing on all links of agricultural and animal husbandry production (including planting and breeding) to provide smart agriculture solutions like environmental monitoring, precision irrigation, and intelligent breeding. By real-time collecting agricultural and animal husbandry production data, environmental and meteorological data, etc., it helps farmers improve production efficiency, reduce operation and maintenance costs, and enhance the quality and output value of agricultural products.View details>Data AccessEquipment ManagementAlarm and Early WarningRemote Operation and MaintenanceRemote ControlData Analysis WideIOT focuses on urban sustainable development and utilizes technologies such as the Internet of Things, big data, and cloud computing. Centering on fields like urban heating, water supply, cooling supply, gas supply, and urban lifelines, it remotely monitors various urban data, breaks down data silos, realizes intelligent management of urban operations, improves urban governance efficiency, and enhances the quality of life and sense of happiness of urban residents.View details>Data CollectionRemote MonitoringAlarm and Early WarningRemote ControlRemote MaintenanceData Analysis

WideIOT focuses on urban sustainable development and utilizes technologies such as the Internet of Things, big data, and cloud computing. Centering on fields like urban heating, water supply, cooling supply, gas supply, and urban lifelines, it remotely monitors various urban data, breaks down data silos, realizes intelligent management of urban operations, improves urban governance efficiency, and enhances the quality of life and sense of happiness of urban residents.View details>Data CollectionRemote MonitoringAlarm and Early WarningRemote ControlRemote MaintenanceData Analysis -

Solution

SolutionFactory line IOT system Factory Energy Management Factory Equipment Management Factory Security Monitoring Factory Equipment Network Segmentation Factory Environmental Protection MonitoringEquipment Remote Maintenance Construction Machinery Grain and Oil Processing Machinery Packaging Machinery Printing Machinery and Equipment Textile Machinery and Equipment Food Processing MachineryReservoir Water Level and Dam Safety Irrigation District Informatization Groundwater Dynamic Monitoring River Flood Control and Management Hydrological Monitoring of Rivers and LakesIntelligent Microgrid System Distributed Photovoltaic Monitoring and Management Wind Farm Monitoring and Management Substation Intelligent Monitoring Management Oilfield IoT System Campus and Building Energy Management System Industrial and Commercial PV-Storage-Charging Remote Monitoring for Charging PilesRemote Monitoring of Pumping Station DMA Zone Metering Leakage Monitoring Water Treatment Plant Pump Station Monitoring Integrated Urban-Rural Water SupplyUrban Sewage Treatment Plant Monitoring Remote Monitoring of Solid Waste Disposal Rural Sewage Monitoring Industrial Wastewater Discharge Monitoring Garbage Incineration Treatment Hazardous Gas Emissions Food Waste TreatmentSmart Breeding System Smart Greenhouse Monitoring System Aquaculture Water Quality Monitoring Smart Agricultural IrrigationUrban Lifeline Solutions Smart Cooling Solution Smart Heating System Urban Flooding and Waterlogging Monitoring Urban Underground Drainage Pipeline MonitoringRemote Monitoring of Construction Vehicles Remote Monitoring of Emergency Power Supply Vehicl Remote Monitoring of Water Sprinkler Trucks Remote Monitoring of Cold Chain Transport VehiclesSmart FactoryIntelligent EquipmentHydraulic EngineeringEnergy & ElectricityWater ServicesEnvironmental ProtectionAgriculture & LivestockSmart CitySmart Vehicles On the basis of digital factory, with the purpose of optimizing production process and business operation, intelligent factory uses Internet of Things technology and monitoring technology to strengthen information management services, improve the controllability of production process, reduce manual intervention of production line, reasonably plan scheduling, realize information unification, group unified monitoring, realize product life cycle and spare parts management, and improve the intelligent degree of manufacturing factory, Reduce operation and maintenance costs and promote industrial upgrading of enterprises.View details>Equipment interconnectionEquipment data collectionEquipment data standardizationRemote Maintenance of equipmentProduction line data visualizationProduction line data analysis

On the basis of digital factory, with the purpose of optimizing production process and business operation, intelligent factory uses Internet of Things technology and monitoring technology to strengthen information management services, improve the controllability of production process, reduce manual intervention of production line, reasonably plan scheduling, realize information unification, group unified monitoring, realize product life cycle and spare parts management, and improve the intelligent degree of manufacturing factory, Reduce operation and maintenance costs and promote industrial upgrading of enterprises.View details>Equipment interconnectionEquipment data collectionEquipment data standardizationRemote Maintenance of equipmentProduction line data visualizationProduction line data analysis With the continuous rise in energy costs and increasingly stringent environmental regulations, factories are paying more and more attention to energy management. Traditional energy management methods lack real-time performance and refinement, failing to meet factories' needs for energy efficiency and cost control. Therefore, an advanced energy management solution is required to achieve rational energy utilization and effective cost control.View details>Energy Data CollectionEnergy Consumption AnalysisEnergy Usage Strategy OptimizationEnergy Cost AccountingEnergy Performance uationEnergy Early Warning and Control

With the continuous rise in energy costs and increasingly stringent environmental regulations, factories are paying more and more attention to energy management. Traditional energy management methods lack real-time performance and refinement, failing to meet factories' needs for energy efficiency and cost control. Therefore, an advanced energy management solution is required to achieve rational energy utilization and effective cost control.View details>Energy Data CollectionEnergy Consumption AnalysisEnergy Usage Strategy OptimizationEnergy Cost AccountingEnergy Performance uationEnergy Early Warning and Control Factory equipment is diverse and extensive in quantity. Traditional equipment management methods are inefficient and struggle to meet the demands of modern production. To ensure stable equipment operation, reduce failure rates, extend equipment lifespan, and enhance production efficiency and product quality, an advanced equipment management solution is urgently needed.View details>Centralized Equipment ManagementReal-time Equipment MonitoringEquipment Maintenance InspectionEquipment Failure Early WarningOEE uation and AnalysisFull Lifecycle Management

Factory equipment is diverse and extensive in quantity. Traditional equipment management methods are inefficient and struggle to meet the demands of modern production. To ensure stable equipment operation, reduce failure rates, extend equipment lifespan, and enhance production efficiency and product quality, an advanced equipment management solution is urgently needed.View details>Centralized Equipment ManagementReal-time Equipment MonitoringEquipment Maintenance InspectionEquipment Failure Early WarningOEE uation and AnalysisFull Lifecycle Management Various safety risks exist in factory production processes, such as fire, explosion, and mechanical injury. Traditional safety monitoring methods often suffer from limited coverage and slow response times, making it difficult to effectively prevent and respond to safety incidents. To ensure the safety of factory personnel and equipment while enhancing production safety, a comprehensive and efficient safety monitoring solution is required.View details>Real-time video surveillanceEnvironmental Parameter MonitoringSafety Hazard AlertEmergency ResponseData Storage AnalysisSecurity Compliance Support

Various safety risks exist in factory production processes, such as fire, explosion, and mechanical injury. Traditional safety monitoring methods often suffer from limited coverage and slow response times, making it difficult to effectively prevent and respond to safety incidents. To ensure the safety of factory personnel and equipment while enhancing production safety, a comprehensive and efficient safety monitoring solution is required.View details>Real-time video surveillanceEnvironmental Parameter MonitoringSafety Hazard AlertEmergency ResponseData Storage AnalysisSecurity Compliance Support In the era of industrial internet, many factories operate various industrial control systems encompassing diverse machinery, equipment, sensors, and networks. Vulnerabilities such as IP conflicts and hacker attacks can easily arise, potentially leading to risks including production accidents, equipment damage, and leaks of commercial secrets. An effective device network isolation solution is required to safeguard factory network security and ensure stable production.View details>Quick Device AccessIP Unified PlanningIP Address ConversionCross-subnet accessNetwork Isolation ProtectionDevice Access Control

In the era of industrial internet, many factories operate various industrial control systems encompassing diverse machinery, equipment, sensors, and networks. Vulnerabilities such as IP conflicts and hacker attacks can easily arise, potentially leading to risks including production accidents, equipment damage, and leaks of commercial secrets. An effective device network isolation solution is required to safeguard factory network security and ensure stable production.View details>Quick Device AccessIP Unified PlanningIP Address ConversionCross-subnet accessNetwork Isolation ProtectionDevice Access Control With the continuous improvement of environmental protection regulations and the increasing social attention to environmental protection, factories are required to strictly comply with environmental protection requirements and reduce pollutant emissions. Traditional environmental monitoring methods have problems such as inaccurate data and untimely monitoring, which are difficult to meet the needs of environmental supervision. Therefore, an advanced environmental protection monitoring solution is needed to realize real-time monitoring and effective management of factory environmental protection indicators.View details>Environmental Data CollectionEnvironmental Quality MonitoringEquipment Operation MonitoringAutomatic Alarm and Early WarningData Statistical AnalysisEnvironmental Compliance Management

With the continuous improvement of environmental protection regulations and the increasing social attention to environmental protection, factories are required to strictly comply with environmental protection requirements and reduce pollutant emissions. Traditional environmental monitoring methods have problems such as inaccurate data and untimely monitoring, which are difficult to meet the needs of environmental supervision. Therefore, an advanced environmental protection monitoring solution is needed to realize real-time monitoring and effective management of factory environmental protection indicators.View details>Environmental Data CollectionEnvironmental Quality MonitoringEquipment Operation MonitoringAutomatic Alarm and Early WarningData Statistical AnalysisEnvironmental Compliance Management With the development of Internet of Things technology and cloud platform technology, more and more users want to be able to remotely diagnose and maintain products sold or held through the Internet, which can reduce the time and cost of maintenance engineers to the site, not only It saves a lot of manpower and material costs, and at the same time, it can provide customers with more efficient and high-quality services and reduce customer losses. Therefore, remote diagnosis and remote maintenance have become urgent problems for equipment manufacturers.View details>Device remote configurationDevice remote debuggingEquipment remote maintenanceRemote upload and downloadEquipment remote monitoringPreventive maintenance

With the development of Internet of Things technology and cloud platform technology, more and more users want to be able to remotely diagnose and maintain products sold or held through the Internet, which can reduce the time and cost of maintenance engineers to the site, not only It saves a lot of manpower and material costs, and at the same time, it can provide customers with more efficient and high-quality services and reduce customer losses. Therefore, remote diagnosis and remote maintenance have become urgent problems for equipment manufacturers.View details>Device remote configurationDevice remote debuggingEquipment remote maintenanceRemote upload and downloadEquipment remote monitoringPreventive maintenance Construction machinery comes in a wide variety and is widely distributed. Traditional equipment management methods are inefficient and make it difficult to monitor equipment status and location in real time. Equipment failures can cause delays in construction progress and increase project costs. To enhance the management efficiency of construction machinery and ensure smooth project execution, a remote monitoring solution is required.View details>Real-Time MonitoringFault Early WarningRemote MaintenanceOperations ManagementRemote ControlData Analysis

Construction machinery comes in a wide variety and is widely distributed. Traditional equipment management methods are inefficient and make it difficult to monitor equipment status and location in real time. Equipment failures can cause delays in construction progress and increase project costs. To enhance the management efficiency of construction machinery and ensure smooth project execution, a remote monitoring solution is required.View details>Real-Time MonitoringFault Early WarningRemote MaintenanceOperations ManagementRemote ControlData Analysis In the grain and oil processing industry, equipment is distributed nationwide in large quantities and diverse types. When malfunctions occur, they often go undetected until customers notice abnormalities or even shutdowns, only then notifying equipment manufacturers. This results in severe delays in after-sales maintenance and operations. Troubleshooting relies on dispatching engineers to perform on-site maintenance, which involves heavy travel workloads and high costs. When multiple equipment failures trigger alerts, it easily strains human resources, forcing engineers to endure frequent, grueling business trips.View details>Data CollectionRemote MonitoringAbnormal AlertOperations ManagementRemote MaintenanceData Analysis

In the grain and oil processing industry, equipment is distributed nationwide in large quantities and diverse types. When malfunctions occur, they often go undetected until customers notice abnormalities or even shutdowns, only then notifying equipment manufacturers. This results in severe delays in after-sales maintenance and operations. Troubleshooting relies on dispatching engineers to perform on-site maintenance, which involves heavy travel workloads and high costs. When multiple equipment failures trigger alerts, it easily strains human resources, forcing engineers to endure frequent, grueling business trips.View details>Data CollectionRemote MonitoringAbnormal AlertOperations ManagementRemote MaintenanceData Analysis In modern industrial production, automation systems directly impact a company's production efficiency and profit margins. Packaging machinery serves as a crucial component within these systems, replacing traditional manual labor to reduce costs and enhance efficiency, thereby contributing to the creation of intelligent, automated factories. To ensure the stable and reliable operation of packaging machinery, minimize production downtime caused by equipment failures, and simultaneously reduce increasingly high equipment management and maintenance costs, establishing an efficient, real-time data acquisition and remote monitoring system is essential.View details>Data Acquisition and MonitoringIntelligent Equipment ManagementRemote Equipment ControlIntelligent Fault AlarmRemote Equipment MaintenanceData Report Analysis

In modern industrial production, automation systems directly impact a company's production efficiency and profit margins. Packaging machinery serves as a crucial component within these systems, replacing traditional manual labor to reduce costs and enhance efficiency, thereby contributing to the creation of intelligent, automated factories. To ensure the stable and reliable operation of packaging machinery, minimize production downtime caused by equipment failures, and simultaneously reduce increasingly high equipment management and maintenance costs, establishing an efficient, real-time data acquisition and remote monitoring system is essential.View details>Data Acquisition and MonitoringIntelligent Equipment ManagementRemote Equipment ControlIntelligent Fault AlarmRemote Equipment MaintenanceData Report Analysis In recent years, with the rapid development of the printing industry, printing machinery and equipment have become indispensable tools in modern printing processing. Modern printing machinery is further developing towards the directions of remote automation, linkage and serialization. With the intensifying market competition and the growing prominence of environmental issues, printing enterprises are paying increasing attention to the monitoring and maintenance of equipment. If printing machinery and equipment break down and fail to operate normally, it will not only affect production tasks but also bring severe economic losses. However, the monitoring and maintenance of printing machinery and equipment is a very challenging task. The complexity and diversity of equipment, as well as the intensive production environment, will all increase the difficulty of monitoring and maintenance.View details>Real-time Equipment Monitoring and ManagementRemote Equipment Diagnosis and MaintenanceRemote Equipment Operation and ControlIntelligent After-sales Operation and Maintenance ManagementPredictive Equipment MaintenanceEquipment Data Analysis and Application

In recent years, with the rapid development of the printing industry, printing machinery and equipment have become indispensable tools in modern printing processing. Modern printing machinery is further developing towards the directions of remote automation, linkage and serialization. With the intensifying market competition and the growing prominence of environmental issues, printing enterprises are paying increasing attention to the monitoring and maintenance of equipment. If printing machinery and equipment break down and fail to operate normally, it will not only affect production tasks but also bring severe economic losses. However, the monitoring and maintenance of printing machinery and equipment is a very challenging task. The complexity and diversity of equipment, as well as the intensive production environment, will all increase the difficulty of monitoring and maintenance.View details>Real-time Equipment Monitoring and ManagementRemote Equipment Diagnosis and MaintenanceRemote Equipment Operation and ControlIntelligent After-sales Operation and Maintenance ManagementPredictive Equipment MaintenanceEquipment Data Analysis and Application Textile factories are equipped with a large number of mechanical devices. Traditional management modes make it difficult to grasp the real-time working status of equipment and adjust production schedules in a timely manner. When equipment malfunctions, it puts great demands on the professional skills of staff; delayed maintenance leads to high resource waste and cost expenditure, which seriously impacts order delivery. Traditional equipment management methods can no longer meet the needs of modern production. There is an urgent need to obtain real-time equipment operation status and adjust production plans promptly, so a remote monitoring solution for textile machinery and equipment is imperative.View details>Data CollectionRemote MonitoringFault AlarmFault AlarmOperation and Maintenance ManagementData Analysis

Textile factories are equipped with a large number of mechanical devices. Traditional management modes make it difficult to grasp the real-time working status of equipment and adjust production schedules in a timely manner. When equipment malfunctions, it puts great demands on the professional skills of staff; delayed maintenance leads to high resource waste and cost expenditure, which seriously impacts order delivery. Traditional equipment management methods can no longer meet the needs of modern production. There is an urgent need to obtain real-time equipment operation status and adjust production plans promptly, so a remote monitoring solution for textile machinery and equipment is imperative.View details>Data CollectionRemote MonitoringFault AlarmFault AlarmOperation and Maintenance ManagementData Analysis In the food processing industry, the stable operation and hygienic safety of food processing machinery are of vital importance to ensuring food quality and production safety. Traditional equipment operation and maintenance methods often rely on on-site manual inspection and repair, which are inefficient and difficult to achieve timely response. Equipment failures may lead to interruption of food production, decline in product quality and even food safety issues. To improve the operation and maintenance efficiency of food processing machinery and ensure the continuity and safety of food production, a remote operation and maintenance solution is needed.View details>Equipment Data CollectionOperating Status MonitoringFault Early Warning and AlarmRemote Equipment MaintenanceRemote O&M ManagementEquipment Data Analysis

In the food processing industry, the stable operation and hygienic safety of food processing machinery are of vital importance to ensuring food quality and production safety. Traditional equipment operation and maintenance methods often rely on on-site manual inspection and repair, which are inefficient and difficult to achieve timely response. Equipment failures may lead to interruption of food production, decline in product quality and even food safety issues. To improve the operation and maintenance efficiency of food processing machinery and ensure the continuity and safety of food production, a remote operation and maintenance solution is needed.View details>Equipment Data CollectionOperating Status MonitoringFault Early Warning and AlarmRemote Equipment MaintenanceRemote O&M ManagementEquipment Data Analysis In recent years, influenced by global climate change and human activities, the frequency and intensity of extreme weather events have increased, imposing new and higher demands on the safe operation of reservoir engineering. Therefore, establishing a reservoir rainfall and water level monitoring and dam safety early warning system enables comprehensive control over reservoirs and dams. This system provides reliable data support for flood control, disaster mitigation, peak shaving, and dry-season water supply, ensuring the safe and stable operation of water conservancy facilities.View details>Real-Time MonitoringMap DisplayOverlimit AlertInterconnected and SharedSite ManagementData Analysis

In recent years, influenced by global climate change and human activities, the frequency and intensity of extreme weather events have increased, imposing new and higher demands on the safe operation of reservoir engineering. Therefore, establishing a reservoir rainfall and water level monitoring and dam safety early warning system enables comprehensive control over reservoirs and dams. This system provides reliable data support for flood control, disaster mitigation, peak shaving, and dry-season water supply, ensuring the safe and stable operation of water conservancy facilities.View details>Real-Time MonitoringMap DisplayOverlimit AlertInterconnected and SharedSite ManagementData Analysis The scale of irrigation districts continues to expand, and their level of informatization is steadily improving. By implementing an intelligent irrigation district information monitoring and management system, real-time tracking of water resource changes within the districts is achieved. This plays a vital role in ensuring the safe operation of irrigation projects, optimizing water resource allocation, enhancing water utilization efficiency, and advancing the development of high-standard farmland.View details>Real-Time MonitoringMap DisplaySmart AlertsRemote Intelligent ControlWorkflow ManagementData Analysis

The scale of irrigation districts continues to expand, and their level of informatization is steadily improving. By implementing an intelligent irrigation district information monitoring and management system, real-time tracking of water resource changes within the districts is achieved. This plays a vital role in ensuring the safe operation of irrigation projects, optimizing water resource allocation, enhancing water utilization efficiency, and advancing the development of high-standard farmland.View details>Real-Time MonitoringMap DisplaySmart AlertsRemote Intelligent ControlWorkflow ManagementData Analysis Groundwater is a vital freshwater resource that not only plays a crucial role in ensuring water supply for urban and rural life and production but also serves an indispensable function in safeguarding ecological and environmental security. However, excessive groundwater extraction and water pollution issues in recent years have posed serious threats to groundwater safety.

Groundwater is a vital freshwater resource that not only plays a crucial role in ensuring water supply for urban and rural life and production but also serves an indispensable function in safeguarding ecological and environmental security. However, excessive groundwater extraction and water pollution issues in recent years have posed serious threats to groundwater safety.

By implementing dynamic monitoring and management of groundwater, various groundwater-related problems can be detected in a timely manner. This enables the adoption of appropriate measures to prevent issues such as excessive groundwater extraction and water pollution disasters, ensuring the rational utilization of this limited water resource.View details>Real-Time MonitoringMap DisplayOverlimit AlertData ReissueSite ManagementData Analysis In recent years, the combined effects of global climate change and human activities have intensified, leading to frequent flooding in small and medium-sized rivers. This poses a serious threat to the lives and property of the people. Therefore, implementing real-time online monitoring of small and medium-sized rivers to understand rainfall and water level data and take timely measures can help reduce the occurrence of flooding disasters and better safeguard the lives and property of the people.View details>Real-Time MonitoringMap DisplayOverlimit AlertInformation SharingSite ManagementDecision Analysis

In recent years, the combined effects of global climate change and human activities have intensified, leading to frequent flooding in small and medium-sized rivers. This poses a serious threat to the lives and property of the people. Therefore, implementing real-time online monitoring of small and medium-sized rivers to understand rainfall and water level data and take timely measures can help reduce the occurrence of flooding disasters and better safeguard the lives and property of the people.View details>Real-Time MonitoringMap DisplayOverlimit AlertInformation SharingSite ManagementDecision Analysis Rivers and lakes serve as vital water resources and ecosystems, with their hydrological conditions significantly impacting production, daily life, and the ecological environment in surrounding areas. Traditional hydrological monitoring methods suffer from limitations such as restricted coverage and delayed data updates, making it difficult to achieve real-time, comprehensive oversight of river water levels, flow rates, water quality, and other critical information. To effectively prevent flood disasters, protect water resources, and maintain ecological balance, there is an urgent need for an advanced hydrological monitoring and early warning system for rivers and lakes.View details>Real-time data acquisitionWater Level and Flow MonitoringWater Quality AssessmentAbnormal Condition AlertData Trend AnalysisInformation Sharing Release

Rivers and lakes serve as vital water resources and ecosystems, with their hydrological conditions significantly impacting production, daily life, and the ecological environment in surrounding areas. Traditional hydrological monitoring methods suffer from limitations such as restricted coverage and delayed data updates, making it difficult to achieve real-time, comprehensive oversight of river water levels, flow rates, water quality, and other critical information. To effectively prevent flood disasters, protect water resources, and maintain ecological balance, there is an urgent need for an advanced hydrological monitoring and early warning system for rivers and lakes.View details>Real-time data acquisitionWater Level and Flow MonitoringWater Quality AssessmentAbnormal Condition AlertData Trend AnalysisInformation Sharing Release The role of microgrids in ensuring safe and reliable power supply in the region has been highly recognized by the industry and society. Distributed microgrids have outstanding advantages, but their control is difficult. Therefore, smart microgrids are widely promoted and applied. According to the project characteristics of distributed sites, WideIOT has many successful cases and a complete set of solutions from on-site data collection to platform application.View details>Power Code SupportRich Internet accessData normalizationIntelligent operationHigh reliability and unattendedData Analysis Application

The role of microgrids in ensuring safe and reliable power supply in the region has been highly recognized by the industry and society. Distributed microgrids have outstanding advantages, but their control is difficult. Therefore, smart microgrids are widely promoted and applied. According to the project characteristics of distributed sites, WideIOT has many successful cases and a complete set of solutions from on-site data collection to platform application.View details>Power Code SupportRich Internet accessData normalizationIntelligent operationHigh reliability and unattendedData Analysis Application With the continuous increase in distributed photovoltaic power stations, their operation and management face numerous challenges. For instance, the scattered distribution of stations makes manual inspections difficult and costly; real-time monitoring of equipment status is challenging, leading to delayed fault detection and resolution. To enhance the power generation efficiency of distributed photovoltaic power stations, reduce operational and maintenance costs, and ensure stable system operation, an advanced photovoltaic monitoring and management system is required.View details>Photovoltaic Data AcquisitionPower Generation Efficiency AnalysisEquipment Condition MonitoringFault Early Warning HandlingRemote Operations and Maintenance ManagementEnergy Optimization Scheduling

With the continuous increase in distributed photovoltaic power stations, their operation and management face numerous challenges. For instance, the scattered distribution of stations makes manual inspections difficult and costly; real-time monitoring of equipment status is challenging, leading to delayed fault detection and resolution. To enhance the power generation efficiency of distributed photovoltaic power stations, reduce operational and maintenance costs, and ensure stable system operation, an advanced photovoltaic monitoring and management system is required.View details>Photovoltaic Data AcquisitionPower Generation Efficiency AnalysisEquipment Condition MonitoringFault Early Warning HandlingRemote Operations and Maintenance ManagementEnergy Optimization Scheduling Wind farms are typically located in remote areas, featuring numerous wind turbines spread across vast expanses. Traditional management methods struggle to provide real-time, comprehensive monitoring and maintenance for these turbines. Turbine operation is influenced by various factors, including weather conditions, and equipment failures can lead to power generation interruptions and economic losses. To enhance operational efficiency, reduce maintenance costs, and maximize the utilization of wind energy resources, a comprehensive wind farm monitoring and management system is essential.View details>Equipment Data AcquisitionOperational Status MonitoringFault Diagnosis and Early WarningPower Generation Performance uationRemote Operations and MaintenanceOptimized Scheduling Management

Wind farms are typically located in remote areas, featuring numerous wind turbines spread across vast expanses. Traditional management methods struggle to provide real-time, comprehensive monitoring and maintenance for these turbines. Turbine operation is influenced by various factors, including weather conditions, and equipment failures can lead to power generation interruptions and economic losses. To enhance operational efficiency, reduce maintenance costs, and maximize the utilization of wind energy resources, a comprehensive wind farm monitoring and management system is essential.View details>Equipment Data AcquisitionOperational Status MonitoringFault Diagnosis and Early WarningPower Generation Performance uationRemote Operations and MaintenanceOptimized Scheduling Management As a critical component of the power supply chain, the safe and stable operation of distribution substations is of paramount importance. With the continuous growth in electricity demand and the expansion of grid scale, the increasing number and complex structure of substation equipment make traditional manual inspection and monitoring methods inadequate for real-time, comprehensive surveillance. Equipment failures can lead to power outages, disrupting normal electricity supply to users. To enhance the reliability and safety of distribution substations, an intelligent monitoring system is required.View details>Distribution Data AcquisitionEquipment Condition MonitoringFault Early Warning HandlingPower Quality MonitoringRemote Operations and Maintenance ControlLoad Optimization Management

As a critical component of the power supply chain, the safe and stable operation of distribution substations is of paramount importance. With the continuous growth in electricity demand and the expansion of grid scale, the increasing number and complex structure of substation equipment make traditional manual inspection and monitoring methods inadequate for real-time, comprehensive surveillance. Equipment failures can lead to power outages, disrupting normal electricity supply to users. To enhance the reliability and safety of distribution substations, an intelligent monitoring system is required.View details>Distribution Data AcquisitionEquipment Condition MonitoringFault Early Warning HandlingPower Quality MonitoringRemote Operations and Maintenance ControlLoad Optimization Management In order to realize real-time dynamic monitoring of oilfields, provide accurate data basis for production operation and management decisions, and comprehensively improve the level of safety management, many customers urgently need to build oilfield IoT systems.WideIOT focuses on the overall solution of the Internet of Things, and has corresponding independent research and development products from on-site data collection to the platform, which can meet the various needs of customers for building oilfield systems.View details>Flexible Network ArchitectureEquipment data collectionProcess monitoringReal-time fault alarmDevice remote controlData Analysis Application

In order to realize real-time dynamic monitoring of oilfields, provide accurate data basis for production operation and management decisions, and comprehensively improve the level of safety management, many customers urgently need to build oilfield IoT systems.WideIOT focuses on the overall solution of the Internet of Things, and has corresponding independent research and development products from on-site data collection to the platform, which can meet the various needs of customers for building oilfield systems.View details>Flexible Network ArchitectureEquipment data collectionProcess monitoringReal-time fault alarmDevice remote controlData Analysis Application With the continuous expansion of campus and building scales, energy consumption is also increasing. Traditional energy management methods lack refinement and intelligence, making it impossible to effectively reduce energy costs and improve energy utilization efficiency. To achieve energy conservation and emission reduction goals, lower operating costs, and enhance the energy management level of campuses and buildings, an advanced energy management system is required.View details>Energy Data CollectionEnergy Consumption Analysis and uationEnergy Conservation Strategy FormulationIntelligent Equipment ControlEnergy Cost AccountingEnergy Performance Improvement

With the continuous expansion of campus and building scales, energy consumption is also increasing. Traditional energy management methods lack refinement and intelligence, making it impossible to effectively reduce energy costs and improve energy utilization efficiency. To achieve energy conservation and emission reduction goals, lower operating costs, and enhance the energy management level of campuses and buildings, an advanced energy management system is required.View details>Energy Data CollectionEnergy Consumption Analysis and uationEnergy Conservation Strategy FormulationIntelligent Equipment ControlEnergy Cost AccountingEnergy Performance Improvement In the industrial and commercial sector, there are high requirements for the reliability of power supply and cost control. Meanwhile, with the widespread application of photovoltaic, energy storage and charging facilities, how to achieve efficient coordination and optimized management of these energy devices has become a key issue. Traditional management methods are unable to meet the needs of integrated management of multiple energy devices, and cannot give full play to the comprehensive benefits of the energy system. To improve industrial and commercial energy utilization efficiency, reduce electricity costs and ensure the stability of power supply, an integrated PV-storage-charging (EMS) monitoring system is required.View details>PV and Energy Storage SynergyCharging Facilities ManagementEnergy Data MonitoringLoad Forecast and AnalysisIntelligent Equipment ControlEmergency Power Supply Support

In the industrial and commercial sector, there are high requirements for the reliability of power supply and cost control. Meanwhile, with the widespread application of photovoltaic, energy storage and charging facilities, how to achieve efficient coordination and optimized management of these energy devices has become a key issue. Traditional management methods are unable to meet the needs of integrated management of multiple energy devices, and cannot give full play to the comprehensive benefits of the energy system. To improve industrial and commercial energy utilization efficiency, reduce electricity costs and ensure the stability of power supply, an integrated PV-storage-charging (EMS) monitoring system is required.View details>PV and Energy Storage SynergyCharging Facilities ManagementEnergy Data MonitoringLoad Forecast and AnalysisIntelligent Equipment ControlEmergency Power Supply Support With the popularization of electric vehicles, the number of charging piles is constantly increasing. Charging piles are widely and dispersedly distributed, making it difficult for traditional management methods to conduct real-time monitoring and effective maintenance of them. Charging pile faults may prevent users from charging normally and affect user experience. To improve the operational efficiency of charging piles, ensure the quality of charging services, and reduce operation and maintenance costs, a remote monitoring and management system is required.View details>EV Charging Pile Status MonitoringCharging Data StatisticsFault Early Warning and HandlingRemote Parameter ConfigurationRemote Device ManagementOperational Data Analysis

With the popularization of electric vehicles, the number of charging piles is constantly increasing. Charging piles are widely and dispersedly distributed, making it difficult for traditional management methods to conduct real-time monitoring and effective maintenance of them. Charging pile faults may prevent users from charging normally and affect user experience. To improve the operational efficiency of charging piles, ensure the quality of charging services, and reduce operation and maintenance costs, a remote monitoring and management system is required.View details>EV Charging Pile Status MonitoringCharging Data StatisticsFault Early Warning and HandlingRemote Parameter ConfigurationRemote Device ManagementOperational Data Analysis With the development of cities, pumping stations, as water supply hubs, play a very important role in residential and industrial water use. There are more and more pumping stations, and their distribution is scattered. Issues that water companies must consider. For the traditional monitoring of pumping stations, the staff is used to check regularly, and sometimes the personnel are negligent, resulting in abnormal operation of the pumping station. At the same time, this method is very troublesome for the monitoring of multiple pumping stations; the data between different pumping stations cannot be effectively integrated. Together, data warning and equipment maintenance cannot be carried out through big data. Therefore, in this context, WideIOT adopts the industrial intelligent gateway to realize the collection and processing with the pump room PLC to remotely monitor the pumping station, and at the same time realizes the data of the pumping station through the WideIOT cloud platform or the customer's self-developed cloud platform. Forecasting, equipment remote maintenance and data sharing.View details>Equipment remote monitoringData is online in real timeEfficient fault alarmEquipment remote maintenanceProcess flow visualizationData report analysis

With the development of cities, pumping stations, as water supply hubs, play a very important role in residential and industrial water use. There are more and more pumping stations, and their distribution is scattered. Issues that water companies must consider. For the traditional monitoring of pumping stations, the staff is used to check regularly, and sometimes the personnel are negligent, resulting in abnormal operation of the pumping station. At the same time, this method is very troublesome for the monitoring of multiple pumping stations; the data between different pumping stations cannot be effectively integrated. Together, data warning and equipment maintenance cannot be carried out through big data. Therefore, in this context, WideIOT adopts the industrial intelligent gateway to realize the collection and processing with the pump room PLC to remotely monitor the pumping station, and at the same time realizes the data of the pumping station through the WideIOT cloud platform or the customer's self-developed cloud platform. Forecasting, equipment remote maintenance and data sharing.View details>Equipment remote monitoringData is online in real timeEfficient fault alarmEquipment remote maintenanceProcess flow visualizationData report analysis During long-term operation, water supply networks experience issues such as pipe aging and damage, leading to water leakage. Traditional leakage detection methods are inefficient and struggle to accurately locate leak points. To reduce leakage rates in water supply networks and enhance water resource utilization efficiency, an advanced DMA zone metering leakage monitoring system is required.View details>Water Flow Data AcquisitionPressure Distribution MonitoringLeakage Alarm LocalizationLeakage Data AnalysisZone Metering ManagementMaintenance Decision Support

During long-term operation, water supply networks experience issues such as pipe aging and damage, leading to water leakage. Traditional leakage detection methods are inefficient and struggle to accurately locate leak points. To reduce leakage rates in water supply networks and enhance water resource utilization efficiency, an advanced DMA zone metering leakage monitoring system is required.View details>Water Flow Data AcquisitionPressure Distribution MonitoringLeakage Alarm LocalizationLeakage Data AnalysisZone Metering ManagementMaintenance Decision Support Pump stations are critical components of water supply systems, with their operational status directly impacting the stability and reliability of water delivery. Traditional pump station management relies on manual inspections and operations, resulting in low efficiency and difficulty in achieving real-time monitoring. With the advancement of automation technology, an advanced monitoring and management system is required to enhance pump station operational efficiency, reduce maintenance costs, and enable unmanned operation.View details>Pump Station Data AcquisitionEquipment Condition MonitoringFault Early Warning HandlingEnergy Consumption Optimization ControlRemote Dispatch ManagementSafety Protection Guarantee

Pump stations are critical components of water supply systems, with their operational status directly impacting the stability and reliability of water delivery. Traditional pump station management relies on manual inspections and operations, resulting in low efficiency and difficulty in achieving real-time monitoring. With the advancement of automation technology, an advanced monitoring and management system is required to enhance pump station operational efficiency, reduce maintenance costs, and enable unmanned operation.View details>Pump Station Data AcquisitionEquipment Condition MonitoringFault Early Warning HandlingEnergy Consumption Optimization ControlRemote Dispatch ManagementSafety Protection Guarantee With the acceleration of urban-rural integration, there is a need to achieve unified planning, management, and services for water supply across both urban and rural areas. Traditional management approaches, which operate in isolation, have led to issues such as uneven water distribution and unstable water quality. To integrate urban and rural water resources, enhance service quality, and ensure water safety for all residents, an information management system is required.View details>Water Supply Data CollectionReal-time Water Quality MonitoringOptimized Pipeline Network SchedulingEmergency Water Supply AssuranceRemote Operations and Maintenance ManagementData Analytics Applications

With the acceleration of urban-rural integration, there is a need to achieve unified planning, management, and services for water supply across both urban and rural areas. Traditional management approaches, which operate in isolation, have led to issues such as uneven water distribution and unstable water quality. To integrate urban and rural water resources, enhance service quality, and ensure water safety for all residents, an information management system is required.View details>Water Supply Data CollectionReal-time Water Quality MonitoringOptimized Pipeline Network SchedulingEmergency Water Supply AssuranceRemote Operations and Maintenance ManagementData Analytics Applications The treatment process at municipal wastewater treatment plants is complex, involving numerous pieces of equipment and operational steps. Traditional management methods rely on manual inspections and record-keeping, resulting in delayed and inaccurate data acquisition that hinders comprehensive, real-time monitoring of the treatment process. Additionally, equipment failures can cause treatment interruptions, compromising compliance with discharge standards. To enhance treatment efficiency, reduce operational costs, and ensure stable compliance with effluent quality standards, an advanced remote monitoring system is urgently needed.View details>Real-time data acquisitionEquipment Condition MonitoringWater Quality Compliance AlertEnergy Consumption Analysis and OptimizationRemote Operations ManagementRapid Troubleshooting

The treatment process at municipal wastewater treatment plants is complex, involving numerous pieces of equipment and operational steps. Traditional management methods rely on manual inspections and record-keeping, resulting in delayed and inaccurate data acquisition that hinders comprehensive, real-time monitoring of the treatment process. Additionally, equipment failures can cause treatment interruptions, compromising compliance with discharge standards. To enhance treatment efficiency, reduce operational costs, and ensure stable compliance with effluent quality standards, an advanced remote monitoring system is urgently needed.View details>Real-time data acquisitionEquipment Condition MonitoringWater Quality Compliance AlertEnergy Consumption Analysis and OptimizationRemote Operations ManagementRapid Troubleshooting The solid waste treatment process involves multiple stages including collection, transportation, storage, and disposal, presenting significant management challenges. Traditional management methods struggle to monitor the real-time operational status of waste treatment equipment and waste inventory levels, often resulting in inefficient processing and environmental pollution. To enhance the efficiency and environmental performance of solid waste treatment, a remote monitoring system is required to comprehensively oversee and manage the entire treatment process.View details>Real-time data acquisitionEquipment Operation MonitoringWaste Stockpile AlertEnvironmental Impact MonitoringRemote Operations and Maintenance SchedulingData Analytics Applications

The solid waste treatment process involves multiple stages including collection, transportation, storage, and disposal, presenting significant management challenges. Traditional management methods struggle to monitor the real-time operational status of waste treatment equipment and waste inventory levels, often resulting in inefficient processing and environmental pollution. To enhance the efficiency and environmental performance of solid waste treatment, a remote monitoring system is required to comprehensively oversee and manage the entire treatment process.View details>Real-time data acquisitionEquipment Operation MonitoringWaste Stockpile AlertEnvironmental Impact MonitoringRemote Operations and Maintenance SchedulingData Analytics Applications Most of the rural sewage is relatively remote and scattered, and it is necessary to centrally monitor the real-time monitoring of the village sewage stations under its jurisdiction, including the operation status of all equipment, the online status of water quality, and video camera images. Integrate the relationship between the process and the process use, and analyze a set of optimized energy and process solutions to reduce operation and maintenance costs.View details>Equipment remote monitoringData is online in real timeEquipment remote maintenanceBig data intelligent applicationEfficient fault alarmData report analysis

Most of the rural sewage is relatively remote and scattered, and it is necessary to centrally monitor the real-time monitoring of the village sewage stations under its jurisdiction, including the operation status of all equipment, the online status of water quality, and video camera images. Integrate the relationship between the process and the process use, and analyze a set of optimized energy and process solutions to reduce operation and maintenance costs.View details>Equipment remote monitoringData is online in real timeEquipment remote maintenanceBig data intelligent applicationEfficient fault alarmData report analysis With increasingly stringent environmental requirements, enterprises must strictly control wastewater discharge to ensure compliance with environmental standards. However, some companies engage in illegal discharge or exceed emission limits, making it difficult for traditional regulatory methods to achieve real-time, effective oversight of industrial wastewater discharge. To strengthen supervision of industrial wastewater discharge and safeguard ecological and environmental security, an advanced wastewater discharge monitoring system is required.View details>Emissions Data CollectionWater Quality Exceedance AlertData Storage AnalysisRemote Supervision and Law EnforcementEmissions Trend ForecastCompliance Management Support

With increasingly stringent environmental requirements, enterprises must strictly control wastewater discharge to ensure compliance with environmental standards. However, some companies engage in illegal discharge or exceed emission limits, making it difficult for traditional regulatory methods to achieve real-time, effective oversight of industrial wastewater discharge. To strengthen supervision of industrial wastewater discharge and safeguard ecological and environmental security, an advanced wastewater discharge monitoring system is required.View details>Emissions Data CollectionWater Quality Exceedance AlertData Storage AnalysisRemote Supervision and Law EnforcementEmissions Trend ForecastCompliance Management Support Garbage incineration treatment is an important way to achieve garbage reduction, harmlessness and resource utilization, but the incineration process has high requirements for equipment and technology. Traditional monitoring methods make it difficult to grasp the operation status and combustion conditions of incineration equipment in real time and accurately, which is prone to problems such as insufficient combustion and excessive pollutant emissions. To ensure the safe and efficient operation of garbage incineration treatment and reduce environmental pollution, an advanced remote monitoring system is required.View details>Real-time Data CollectionEquipment Status MonitoringCombustion Condition OptimizationPollutant Emission MonitoringFault Early Warning and HandlingRemote Operation and Maintenance Management

Garbage incineration treatment is an important way to achieve garbage reduction, harmlessness and resource utilization, but the incineration process has high requirements for equipment and technology. Traditional monitoring methods make it difficult to grasp the operation status and combustion conditions of incineration equipment in real time and accurately, which is prone to problems such as insufficient combustion and excessive pollutant emissions. To ensure the safe and efficient operation of garbage incineration treatment and reduce environmental pollution, an advanced remote monitoring system is required.View details>Real-time Data CollectionEquipment Status MonitoringCombustion Condition OptimizationPollutant Emission MonitoringFault Early Warning and HandlingRemote Operation and Maintenance Management In places such as industrial production sites and chemical industrial parks, a large amount of hazardous gas emissions are generated, posing a serious threat to air quality and human health. Traditional monitoring methods have problems such as limited monitoring range and untimely data updates, making it difficult to conduct comprehensive and real-time monitoring of hazardous gas emissions. To effectively monitor hazardous gas emissions and ensure air quality and public health, an advanced online monitoring system is required.View details>Real-time Data CollectionOver-standard Early Warning and AlarmEmission Trend AnalysisRegional Pollution AssessmentRemote Supervision and ControlData Sharing and Release

In places such as industrial production sites and chemical industrial parks, a large amount of hazardous gas emissions are generated, posing a serious threat to air quality and human health. Traditional monitoring methods have problems such as limited monitoring range and untimely data updates, making it difficult to conduct comprehensive and real-time monitoring of hazardous gas emissions. To effectively monitor hazardous gas emissions and ensure air quality and public health, an advanced online monitoring system is required.View details>Real-time Data CollectionOver-standard Early Warning and AlarmEmission Trend AnalysisRegional Pollution AssessmentRemote Supervision and ControlData Sharing and Release Food waste contains a large amount of organic matter. Improper treatment of it is likely to cause environmental pollution and resource waste. Traditional food waste treatment methods lack effective monitoring means, making it difficult to grasp the operation status of treatment equipment and treatment effects in real time. Meanwhile, problems such as odors and other environmental pollution may arise during the food waste treatment process. To standardize food waste treatment, improve resource utilization efficiency, and reduce environmental pollution, a remote monitoring system is required.View details>Real-time Data CollectionEquipment Operation MonitoringOdor Emission MonitoringResource Conversion uationFault Early Warning and MaintenanceRemote Operation Management

Food waste contains a large amount of organic matter. Improper treatment of it is likely to cause environmental pollution and resource waste. Traditional food waste treatment methods lack effective monitoring means, making it difficult to grasp the operation status of treatment equipment and treatment effects in real time. Meanwhile, problems such as odors and other environmental pollution may arise during the food waste treatment process. To standardize food waste treatment, improve resource utilization efficiency, and reduce environmental pollution, a remote monitoring system is required.View details>Real-time Data CollectionEquipment Operation MonitoringOdor Emission MonitoringResource Conversion uationFault Early Warning and MaintenanceRemote Operation Management Smart farming is from "people + process + management" to "digital + intelligence", from refined management to digital and intelligent operation. In the past, the core advantage of the pig industry was the refinement of management, and its business model was usually based on "people + process + management", which brought cost reduction and improved operating efficiency, which was also the main reason for the pig group to win. reason. In the era of digital economy, with the development of big data, 5G, Internet of Things and other technologies, "digital + intelligent" operation, that is, digital and intelligent operation, has gradually become the core competitiveness of group enterprises.View details>Device interconnectionData real-time monitoringEquipment remote maintenanceData Analysis ApplicationReal-time fault alarmProcess monitoring

Smart farming is from "people + process + management" to "digital + intelligence", from refined management to digital and intelligent operation. In the past, the core advantage of the pig industry was the refinement of management, and its business model was usually based on "people + process + management", which brought cost reduction and improved operating efficiency, which was also the main reason for the pig group to win. reason. In the era of digital economy, with the development of big data, 5G, Internet of Things and other technologies, "digital + intelligent" operation, that is, digital and intelligent operation, has gradually become the core competitiveness of group enterprises.View details>Device interconnectionData real-time monitoringEquipment remote maintenanceData Analysis ApplicationReal-time fault alarmProcess monitoring Greenhouse cultivation requires precise control of environmental conditions—such as temperature, humidity, and light—to meet crop growth needs. Traditional greenhouse management relies on manual labor and experience, making it difficult to achieve accurate environmental regulation. This often leads to poor crop growth and reduced yields. To enhance greenhouse cultivation efficiency and management standards, a remote monitoring system is essential.View details>Real-time data acquisitionCrop Growth MonitoringIrrigation and Fertilization ManagementPest and Disease AlertRemote Greenhouse ManagementData Analytics Applications

Greenhouse cultivation requires precise control of environmental conditions—such as temperature, humidity, and light—to meet crop growth needs. Traditional greenhouse management relies on manual labor and experience, making it difficult to achieve accurate environmental regulation. This often leads to poor crop growth and reduced yields. To enhance greenhouse cultivation efficiency and management standards, a remote monitoring system is essential.View details>Real-time data acquisitionCrop Growth MonitoringIrrigation and Fertilization ManagementPest and Disease AlertRemote Greenhouse ManagementData Analytics Applications Aquaculture demands high water quality standards, as fluctuations in water conditions directly impact the growth and health of aquatic animals. Traditional methods of water quality monitoring and adjustment primarily rely on manual periodic testing and empirical judgment, resulting in issues such as delayed monitoring and inaccurate adjustments. To ensure stable water quality in aquaculture and enhance production efficiency, a water quality monitoring system is essential.View details>Water Quality Data AcquisitionDissolved Oxygen Content MonitoringWater Quality Balance ControlAmmonia Nitrogen Content AlertRemote Equipment ControlAquaculture Data Analysis