Real-time Cooling Data Collection

Cooling Demand Analysis and Forecasting

Optimized Equipment Operation Control

Refined Energy Consumption Cost Accounting

System Fault Early Warning and Diagnosis

Cooling Effect Evaluation and Feedback

Home

Product

Industries

Solution

About Us

Service Support

Contact Us

Real-time Cooling Data Collection

Cooling Demand Analysis and Forecasting

Optimized Equipment Operation Control

Refined Energy Consumption Cost Accounting

System Fault Early Warning and Diagnosis

Cooling Effect Evaluation and Feedback

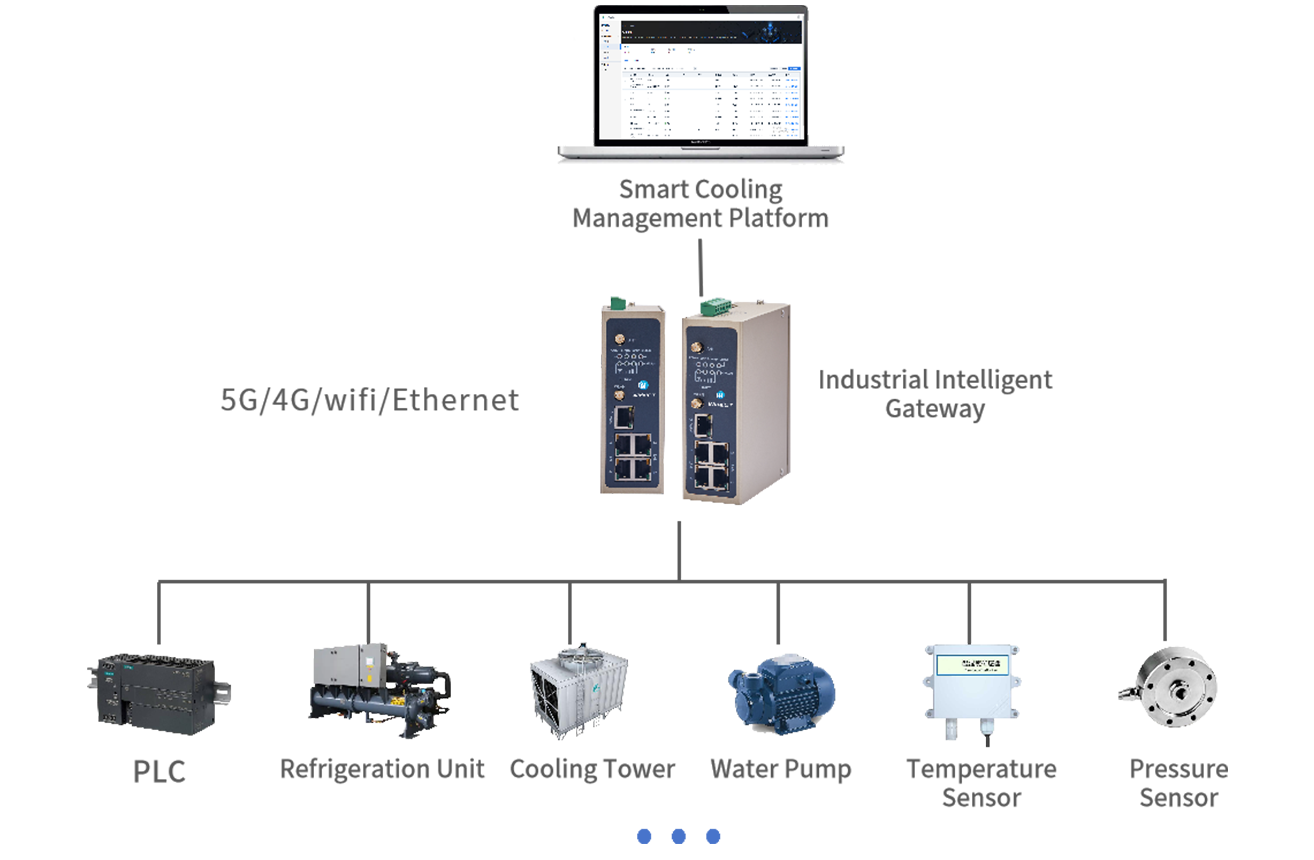

Switch

Using WideIOT's industrial smart gateway, real-time operational data is collected from refrigeration units, cooling towers, water pumps, and other equipment within the cooling supply system. This includes parameters such as temperature, pressure, flow rate, and power consumption. Simultaneously, data on indoor and outdoor ambient temperature, humidity, and cooling demand across different zones is gathered. The collected data is transmitted to the smart cooling management platform. Through data analysis and algorithmic models, the platform predicts cooling demand for various time periods and zones, optimizes equipment operating parameters, and enables intelligent control of the equipment. When equipment anomalies or potential failures occur, the system promptly issues alerts and provides diagnostic insights and troubleshooting recommendations. Furthermore, the platform features energy consumption cost accounting capabilities, delivering detailed energy usage reports and cost analyses to support cost control and energy-saving decision-making.

Comprehensively grasp cooling system and environmental parameters to provide a data foundation for optimized control.

Provide precise cooling according to actual demand, avoid cooling capacity waste, and improve energy utilization efficiency.

Prolong equipment service life, reduce equipment maintenance costs, and ensure stable operation of the system.

Clearly understand energy consumption and cost composition to provide a basis for energy conservation and cost control.

Automatically issue alarms and early warnings, detect and handle faults in advance, and reduce downtime and losses.

Continuously optimize cooling strategies through data analysis to improve cooling quality and user satisfaction.