Data Collection

Remote Monitoring

Fault Alarm

Equipment Management

Operation and Maintenance Management

Data Analysis

Home

Product

Industries

Solution

About Us

Service Support

Contact Us

Data Collection

Remote Monitoring

Fault Alarm

Equipment Management

Operation and Maintenance Management

Data Analysis

Switch

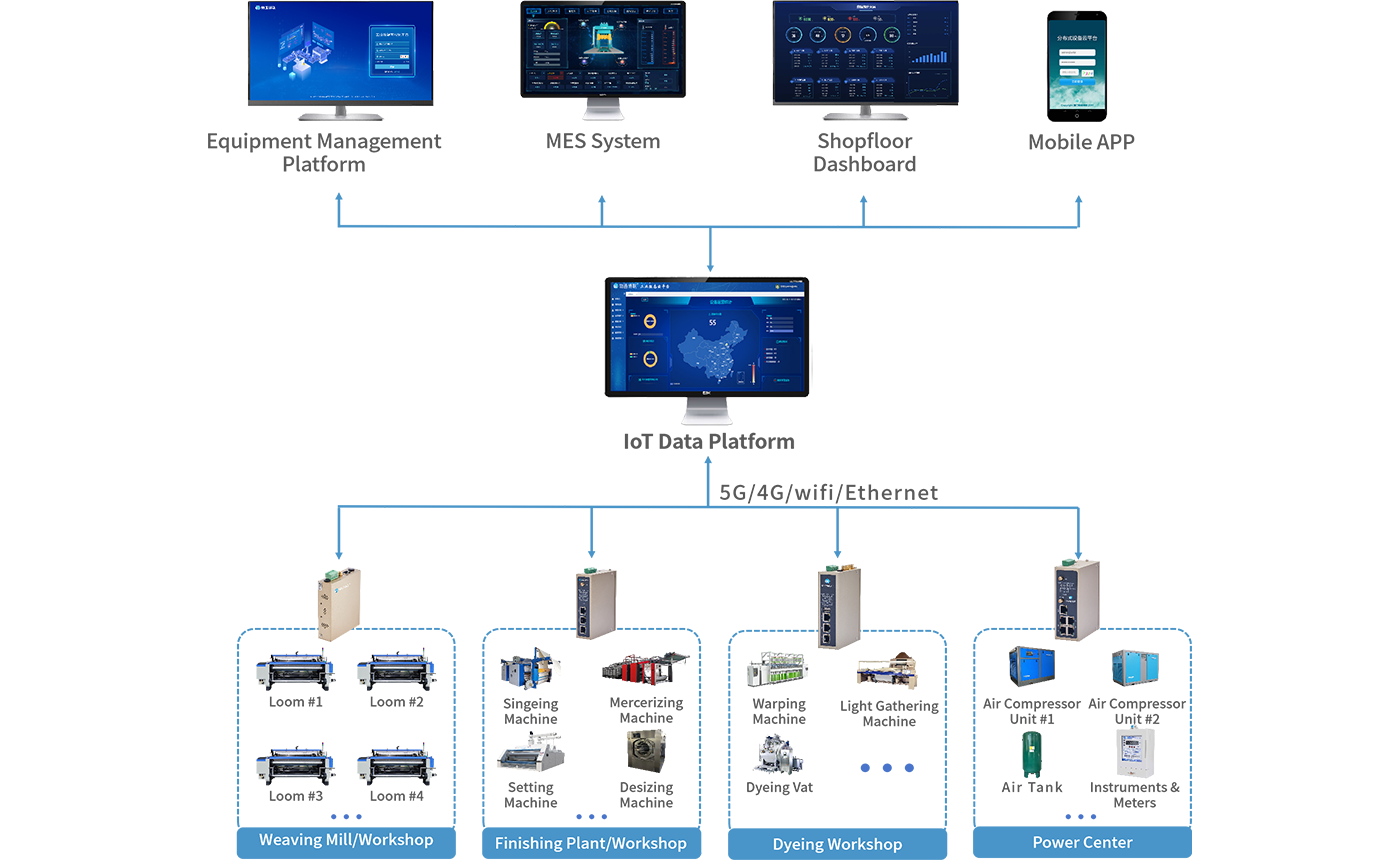

WideIOT has launched a textile factory equipment monitoring and operation and maintenance system solution based on PLC Internet of Things technology. The system connects to the PLC controllers of textile machinery via industrial intelligent gateways to collect data, and communicates in real time with the WideIOT equipment operation and maintenance management platform through 5G/4G, WiFi, Ethernet and other means, providing efficient and convenient management tools for equipment management and operation and maintenance management. The gateway can also forward data to the MES system, and analyze various equipment statuses and production parameters in conjunction with data dashboards, thereby helping to formulate scientific and reasonable business strategies and facilitating the digital transformation of textile factories.

The gateway is equipped with powerful intelligent data collection capabilities. It can collect equipment operation status and operating parameters such as voltage, current, temperature, pressure and other data, and transmit them to the Wutong Bolian IOT data middle platform or the factory upper computer in real time.

Remotely view production line equipment operation status, process parameters, alarm events, camera data and other information through mobile phones and computers, improving work flexibility.

By setting alarm rules, automatic alarms are triggered when abnormal equipment data or faults are detected. Notifications are sent to managers and maintenance personnel via WeChat, SMS, email, etc., enabling quick location, diagnosis and measures to reduce unexpected equipment downtime.

Manage the equipment connected to the system in each workshop and production line, establish equipment files, and check information such as equipment type, purchase time, and maintenance date at any time.

Equipment faults automatically generate maintenance work orders. Users can create, claim, submit and view operation and maintenance work order logs, track the progress of work order execution and intervene in a timely manner, realizing visualization of the operation and maintenance process.

Summarize and analyze equipment operation status, real-time data, historical data, alarm data and operation and maintenance data. Realize intelligent analysis of OEE data, output information, equipment utilization rate, etc., to help enterprises make scientific and reasonable decisions.