Real-time Video Surveillance

Environmental Parameter Monitoring

Potential Safety Hazard Early Warning

Emergency Response

Data Storage and Analysis

Safety Compliance Support

Home

Product

Industries

Solution

About Us

Service Support

Contact Us

Real-time Video Surveillance

Environmental Parameter Monitoring

Potential Safety Hazard Early Warning

Emergency Response

Data Storage and Analysis

Safety Compliance Support

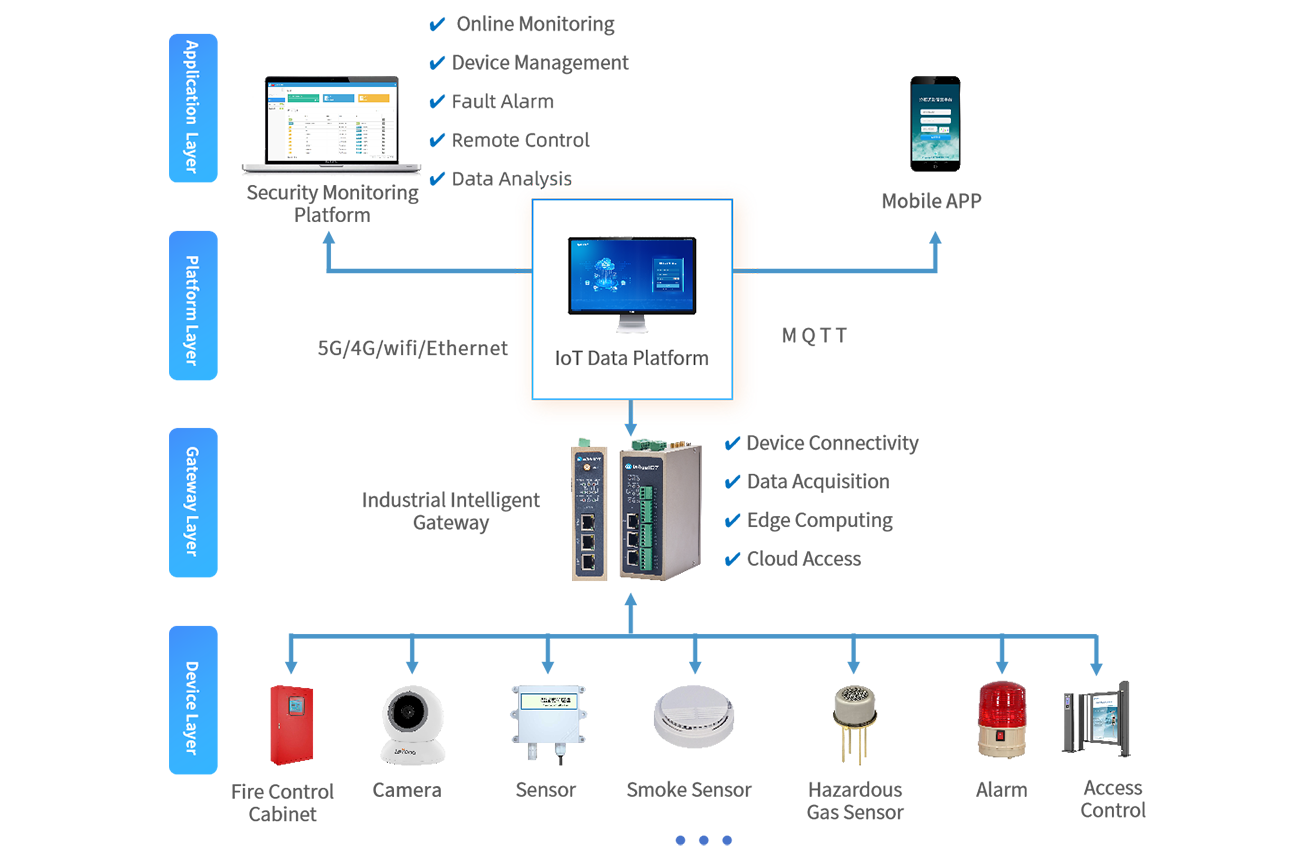

Switch

WideIOT connects production equipment, sensors, cameras, firefighting equipment, security systems, it integrates video surveillance, personnel behavior, and equipment status data for unified management and application. This enables real-time monitoring of factory environmental risks, non-compliant personnel behavior, safety attire violations, and unauthorized vehicle/personnel access. The system automatically triggers alerts, reports incidents, and coordinates emergency response commands, effectively addressing traditional challenges such as high oversight complexity, manual inspection oversights, weak preemptive prevention capabilities, and slow response times. This establishes a smart factory safety supervision solution to reduce the occurrence of safety incidents.

Provide full-range and non-blind-spot monitoring of factory production areas to timely detect and address potential safety hazards, effectively preventing safety accidents.

Real-time monitor environmental parameters (such as temperature, humidity, gas concentration, etc.) to mitigate environment-related safety risks.

Through intelligent alarms, identify potential safety hazards in advance and notify relevant personnel to take corresponding measures, ensuring the safety of equipment and personnel.

In emergency situations, quickly activate the emergency response mechanism, link with fire protection, security and other equipment to handle emergencies promptly and minimize accident losses.

Provide historical data and analysis reports for safety management, helping relevant personnel make more timely and accurate decisions and continuously improve safety management standards.

Through recording and reporting functions, factories can demonstrate compliance and present relevant data during audits and inspections, reducing legal and financial risks caused by non-compliance.