Real-time Monitoring

Fault Early Warning

Remote Maintenance

Operation and Maintenance Management

Remote Control

Data Analysis

Home

Product

Industries

Solution

About Us

Service Support

Contact Us

Real-time Monitoring

Fault Early Warning

Remote Maintenance

Operation and Maintenance Management

Remote Control

Data Analysis

Switch

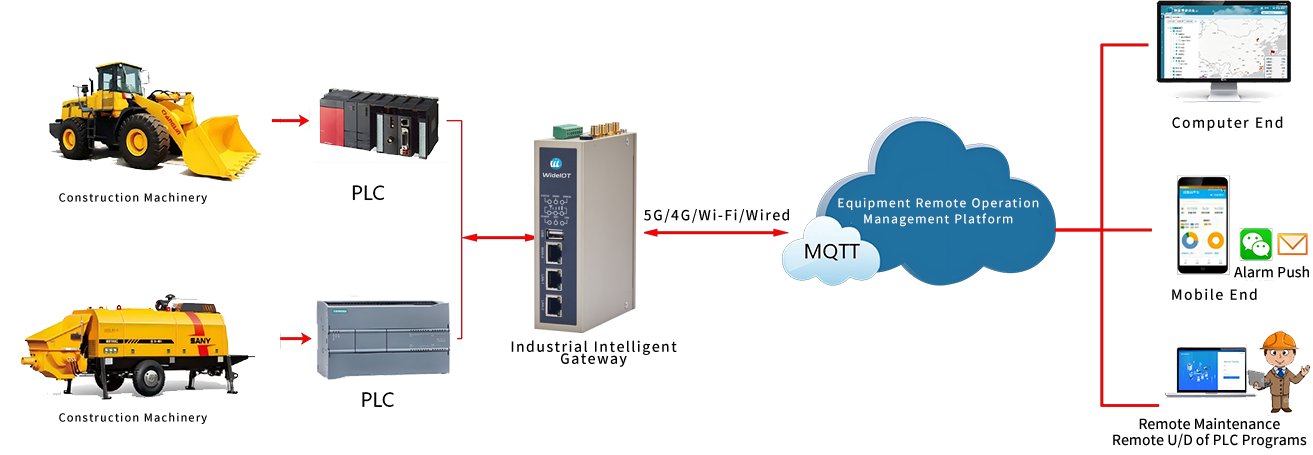

Through WideIOT's industrial smart gateway, controllers, sensors, and other devices in construction machinery are connected to collect real-time data including equipment location, operational status (such as active, idle, or malfunction), operating parameters (like engine RPM, oil pressure, coolant temperature), and fuel consumption. This collected data is transmitted to the equipment operation and maintenance management platform for analysis and processing. When equipment malfunctions occur, timely alerts are issued. Remote maintenance is performed via WideIOT's Equipment Maintenance Express, enhancing maintenance efficiency, reducing operational costs, and enabling comprehensive digital management throughout the equipment's entire lifecycle.

Collect data such as equipment location, rotational speed, and fuel consumption, display it in real time on the platform, and send immediate alerts for abnormal statuses. Help manufacturers keep track of equipment dynamics at all times and avoid information delay.

Based on preset thresholds and data analysis, identify potential equipment faults in advance and promptly notify operation and maintenance engineers. Improve maintenance efficiency, reduce unplanned downtime, and ensure the steady progress of projects.

In case of equipment failure, engineers can perform remote debugging of the equipment's PLC and remote upload/download of programs through the remote maintenance channel, reducing operation and maintenance costs.

Online creation and assignment of maintenance work orders, tracking of work order progress, recording of operation and maintenance history, and visualization of the operation and maintenance process. Improve the efficiency and standardization level of after-sales services.

Under safety authorization, remotely execute operations such as equipment fuel cut-off and start-stop to respond to emergencies like equipment abnormalities and ensure asset safety.

Conduct in-depth mining of equipment operation data to generate decision-making reports for maintenance, procurement, etc. Provide data support for manufacturers to optimize product design and adjust operation and maintenance strategies.