Data Collection and Monitoring

Intelligent Equipment Management

Remote Equipment Control

Intelligent Fault Alarm

Remote Equipment Maintenance

Data Report Analysis

Home

Product

Industries

Solution

About Us

Service Support

Contact Us

Data Collection and Monitoring

Intelligent Equipment Management

Remote Equipment Control

Intelligent Fault Alarm

Remote Equipment Maintenance

Data Report Analysis

Switch

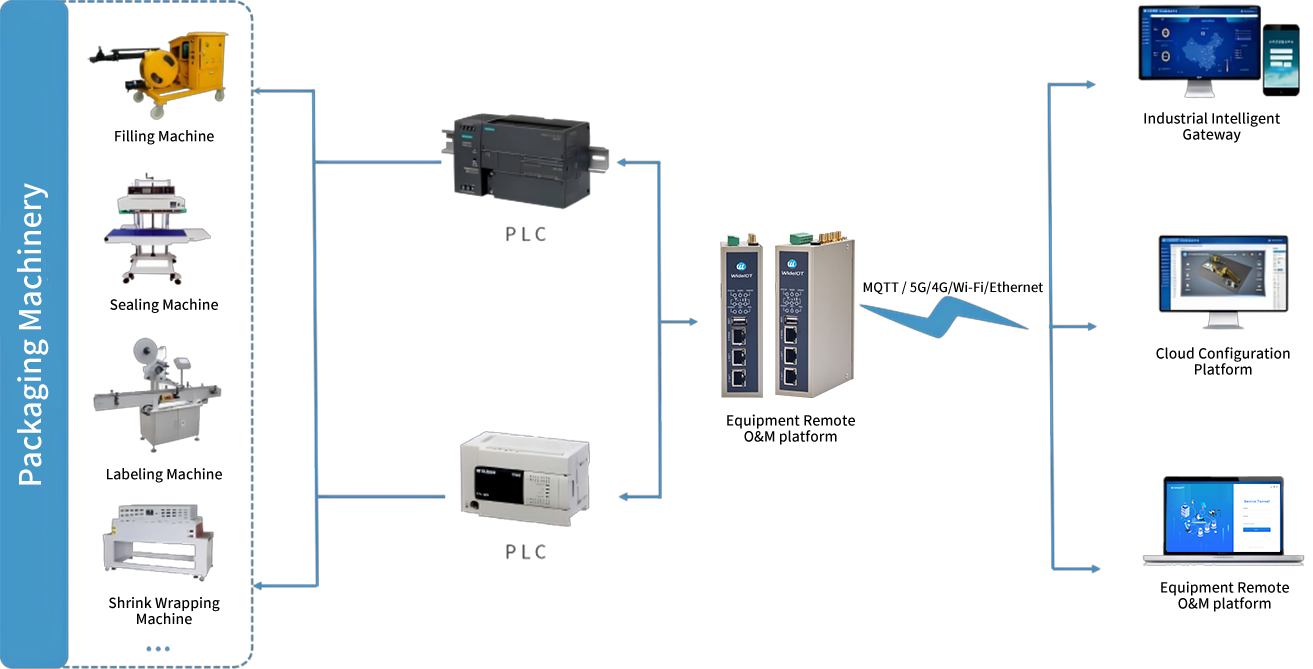

The WideIOT Industrial Smart Gateway features a comprehensive suite of communication protocols and interfaces. By connecting to the PLC controllers of packaging machinery, it enables real-time collection of operational parameters such as equipment status, temperature, pressure, and vibration. Data is transmitted to the cloud platform via 5G, 4G, Wi-Fi, or Ethernet, facilitating remote monitoring, configuration monitoring, equipment management, fault alerts, remote control, remote maintenance, and data analysis. This provides comprehensive oversight of equipment operation, helping enterprises enhance packaging machinery maintenance and management, ensure safe and stable production, and boost productivity. When equipment malfunctions occur, managers receive immediate notifications. Engineers can perform remote fault diagnosis and maintenance through WideIOT's Equipment Maintenance Express, minimizing downtime while effectively improving maintenance efficiency and reducing operational costs.

WideIOT industrial gateway collects data from packaging machinery and equipment. Users can check the real-time operation status and process parameters of the equipment, such as temperature, pressure, current, energy consumption and other data, on mobile phones and computers at any time.

Through the platform, remote management of equipment and gateways connected to the system can be realized. Users can view the quantity, status and specific parameters, and quickly query equipment fault records and maintenance records.

The gateway supports two-way communication with PLC, enabling the platform to reverse control the PLC. It can remotely control equipment start/stop or scheduled on/off commands, improving operation and maintenance efficiency.

By setting alarm thresholds and notification methods, automatic alarms are sent to managers at all levels when data is abnormal. It supports notification methods such as WeChat, SMS and email, facilitating managers to take quick response measures.

Through the equipment maintenance express line, engineers can perform remote debugging and maintenance operations on equipment to solve faults quickly and efficiently. They can also analyze and count maintenance records, establish maintenance models, and realize predictive maintenance.

By analyzing equipment operation efficiency, process parameters and energy consumption data, it can help improve production processes, achieve energy conservation and consumption reduction, and enhance product R&D capabilities.