Equipment Data Collection

Operating Status Monitoring

Fault Early Warning and Alarm

Remote Equipment Maintenance

Remote O&M Management

Equipment Data Analysis

Home

Product

Industries

Solution

About Us

Service Support

Contact Us

Equipment Data Collection

Operating Status Monitoring

Fault Early Warning and Alarm

Remote Equipment Maintenance

Remote O&M Management

Equipment Data Analysis

Switch

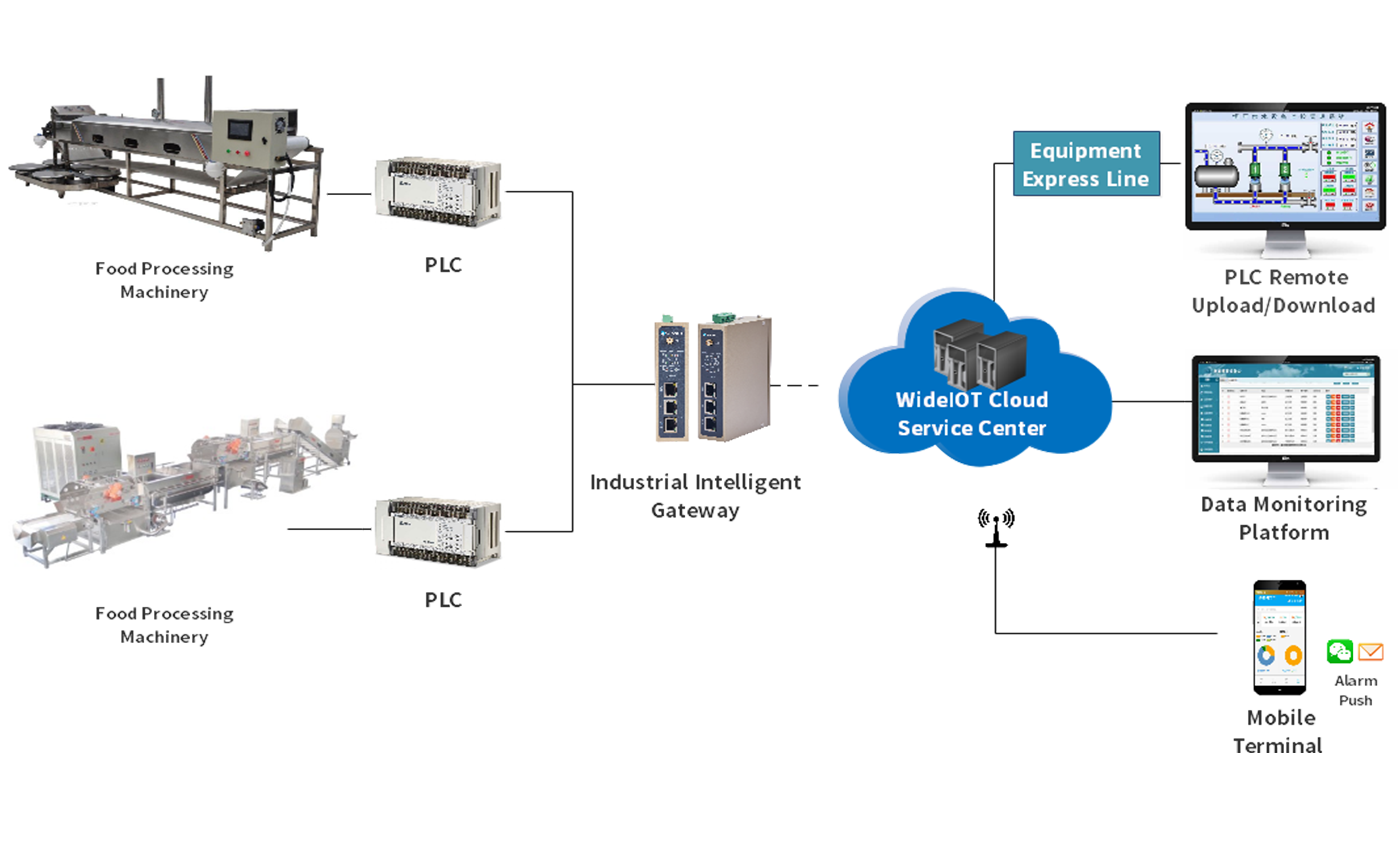

WideIOT provides a remote operation and maintenance (O&M) solution for food processing machinery. Via industrial intelligent gateways, it connects to the control systems of food processing machinery to collect data such as equipment operation parameters (e.g., temperature, pressure) and hygiene indicators (e.g., cleanliness). The data is transmitted to a remote O&M platform through secure networks, where real-time analysis is conducted to monitor the equipment’s operation status and hygiene conditions. When equipment malfunctions or hygiene indicators turn abnormal, O&M personnel are promptly notified to address the issues. Additionally, the solution supports remote O&M operations to ensure the stable running of the machinery.

Gateways can accurately collect various types of data from food processing machinery, providing data support for O&M and production management.

Real-time grasp the operating status of food processing machinery, promptly detect potential issues, and ensure production continuity.

Automatic alarm based on thresholds, early detection of equipment fault hazards, timely diagnosis, and reduction of fault downtime.

Realize remote diagnosis and O&M functions through the equipment maintenance channel, quickly resolve issues, improve O&M efficiency, and reduce O&M costs.

Realize the management of remote O&M work orders, improve service quality, reasonably arrange preventive maintenance, and extend equipment service life.

Analyze equipment data and production data to optimize equipment processes, improve production efficiency and product quality, and enhance product R&D capabilities.