-

PLC Data Acquisition (MES IoT) Solution

2025-12-03 13:34:24

A manufacturing enterprise requires data acquisition from its on-site PLCs and uploading to the MES system. However, the PLCs exhibit poor network adaptability, and the presence of multiple PLC brands poses additional challenges for data acquisition devices.

In response, WideIOT offers a solution based on network segment isolators + industrial smart gateways, enabling fast, stable, and secure data acquisition from on-site PLCs and facilitating external network access to internal network PLC data. Additionally, the system platform provides simple configuration operations and ease of later-stage implementation and maintenance.

-

Addressing Multi-brand PLC Issues: The industrial smart gateway's built-in protocol parsing library swiftly resolves challenges associated with deploying multiple PLC brands on-site.

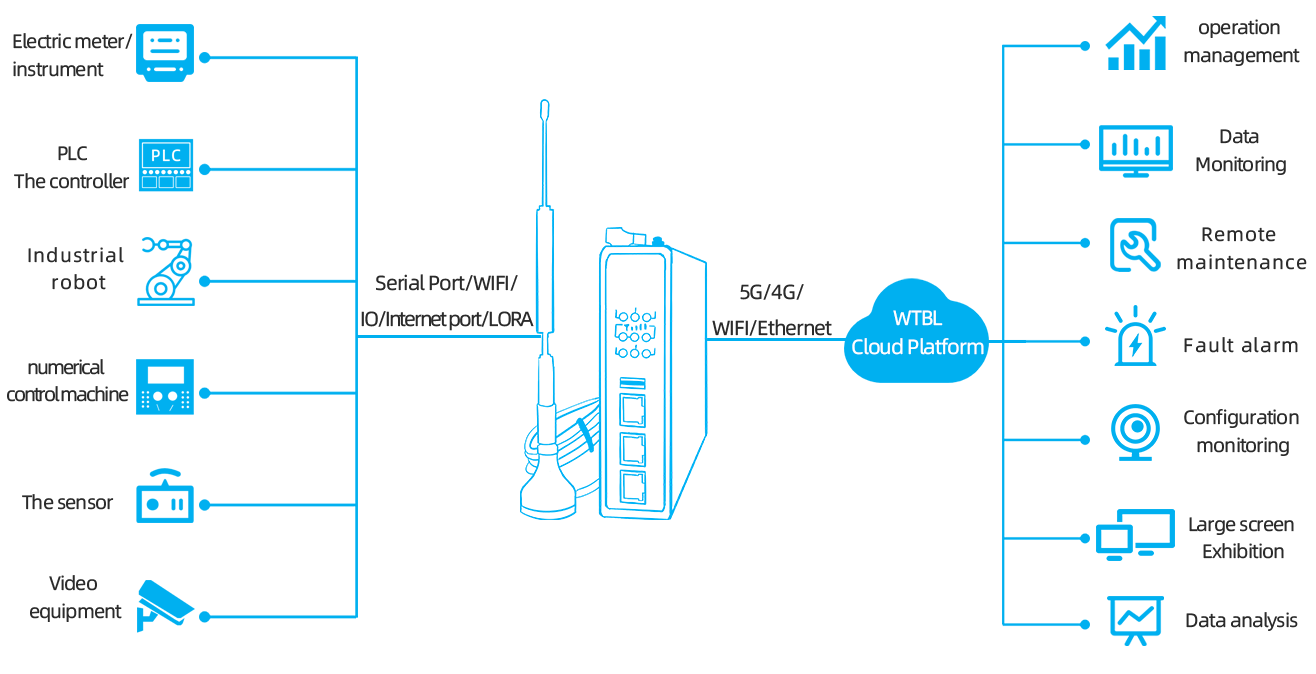

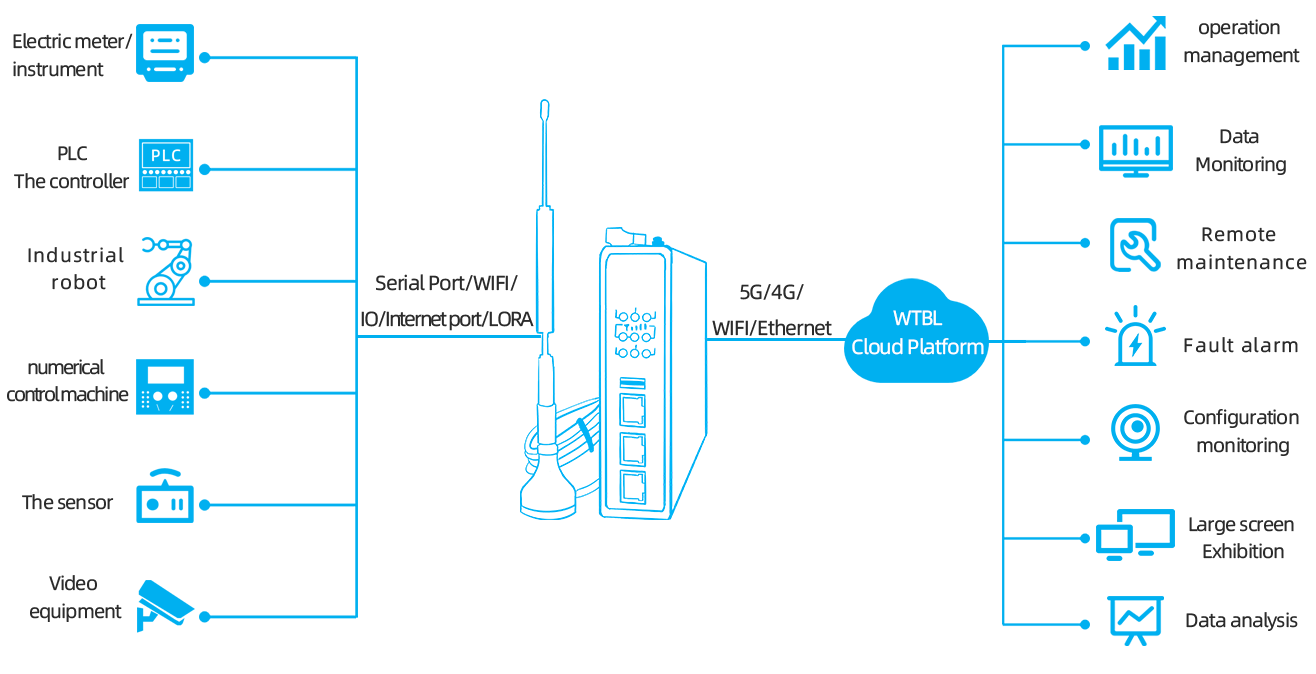

It supports access to PLCs from Siemens, Mitsubishi, Omron, Schneider, Delta, Huyuan, Keyence, Beckhoff, and others, enabling real-time data acquisition and connection to cloud platforms or upper computers' MES systems via 5G/4G/WIFI/Ethernet. This facilitates various applications such as configuration monitoring, data dashboards, fault alarms, and data analysis. -

Resolving PLC Network Adaptability Issues: Network segment isolators are employed to achieve network segment isolation and NAT conversion for PLCs, addressing IP conflicts that prevent internet access.

By implementing NAT and IP mapping, the LAN port IP is mapped to the WAN port IP, enabling network access without altering device IP addresses (eliminating the impact of IP duplication and conflicts on the upper network). The isolator's custom device IP addressing allows for unified IP planning. -

Handling Occupied PLC Communication Interfaces: The industrial smart gateway's serial port forwarding function swiftly resolves issues where PLC communication interfaces are occupied.

Clients can configure the gateway to forward data from one serial port to another, ensuring normal communication of the original serial port data while enabling other upper computer software to communicate and interact with the device through the forwarded serial port.

Furthermore, WideIOT provides a convenient device access and remote maintenance platform, enabling rapid configuration of on-site PLC data acquisition and facilitating remote programming, debugging, and program uploading and downloading operations for PLCs located in different geographical locations. This offers efficient and reliable management tools for production management and control.

-

Go Top

Go Top