-

Screen Printing Machine PLC Data Acquisition IoT Solution

2025-12-03 13:31:12

A screen printing machine, also known as a silk screen printing machine, is an automated mechanical device used for printing text, images, graphics, and other information.

Its working principle involves transferring ink through a silk screen (a thin mesh with holes) onto a substrate (such as paper, plastic, metal, etc.) to achieve printing. It is widely applied in packaging, advertising, textiles, electronics, and various other fields.As business scales expand and equipment is sold across the country, equipment manufacturers often struggle to provide timely and efficient after-sales maintenance services. Dispatching personnel for on-site maintenance incurs significant time consumption and labor costs, adversely affecting the customer's user experience.

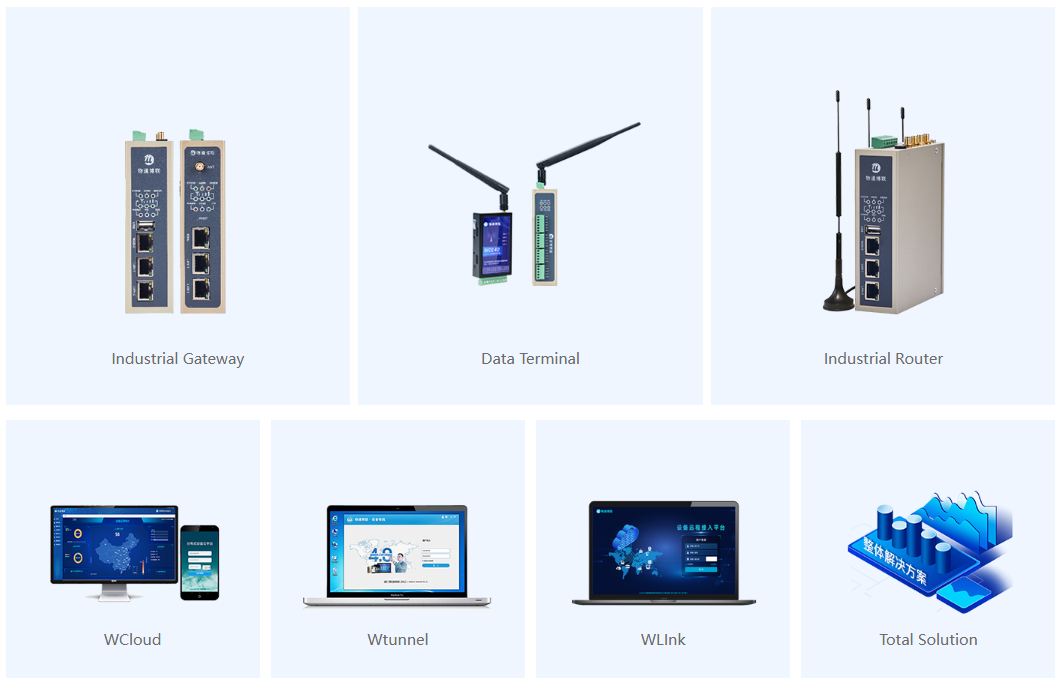

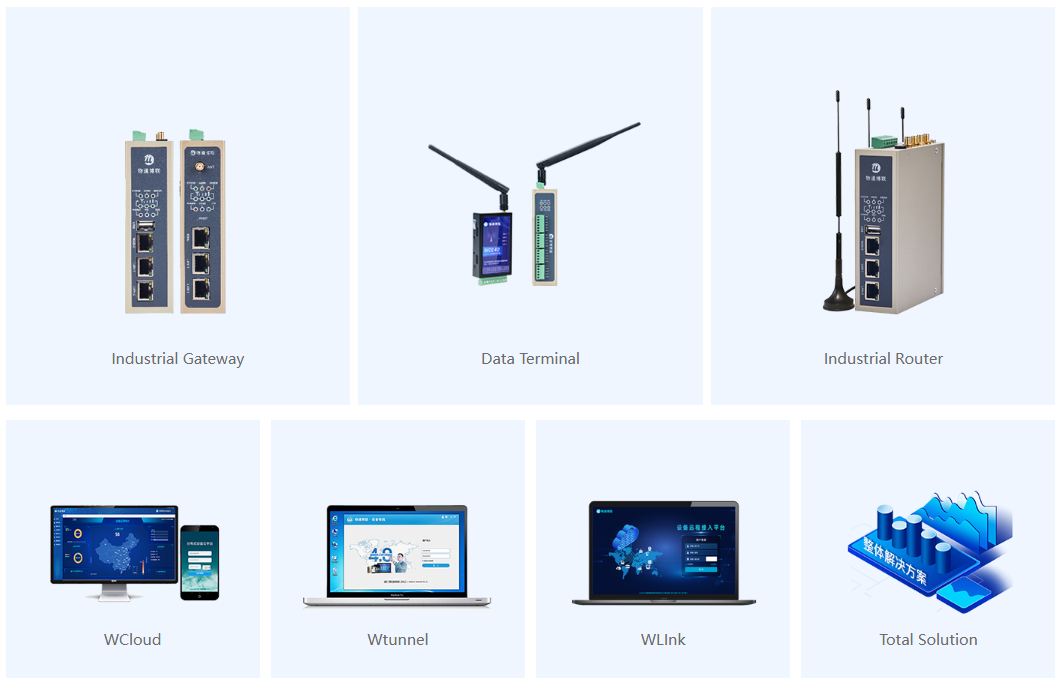

In response, WideIOT offers an IoT system solution for PLC data acquisition in screen printing machines, enabling remote monitoring, control, maintenance, and data analysis to optimize and upgrade O&M services.

By integrating WideIOT's industrial smart gateway into the screen printing machine's PLC, protocol parsing and data acquisition are performed.

The acquired data, including device on/off status, temperature, pressure, speed, and other parameters, is then transmitted to a cloud platform or upper computer (via 5G/4G/WIFI/Ethernet, etc.). Remote control and maintenance capabilities facilitate intelligent management of the production process, allowing timely measures to be taken in case of faults to avoid accidents and economic losses.Through terminals such as smartphones and computers, enterprises can access information on device location distribution, operational status, running parameters, alarm events, and maintenance records anytime and anywhere. This enables PLC remote control, PLC remote programming and debugging, and PLC remote program uploading and downloading operations, enhancing work efficiency and management levels. Additionally, data analysis and optimization provide reliable support for improving maintenance services and strengthening R&D capabilities.

Go Top

Go Top