Wind Farm Monitoring and Management

Ensure Efficient Operation of Wind Farms and Improve Wind Energy Utilizatio

Wind Turbine Data Collection

Operation Status Monitoring

Fault Diagnosis and Early Warning

Power Generation Performance Evaluation

Remote Control and Operation & Maintenance

Optimized Dispatch and Management

Wind farms are typically located in remote areas, featuring numerous wind turbines spread across vast expanses. Traditional management methods struggle to provide real-time, comprehensive monitoring and maintenance for these turbines. Turbine operation is influenced by various factors, including weather conditions, and equipment failures can lead to power generation interruptions and economic losses. To enhance operational efficiency, reduce maintenance costs, and maximize the utilization of wind energy resources, a comprehensive wind farm monitoring and management system is essential.

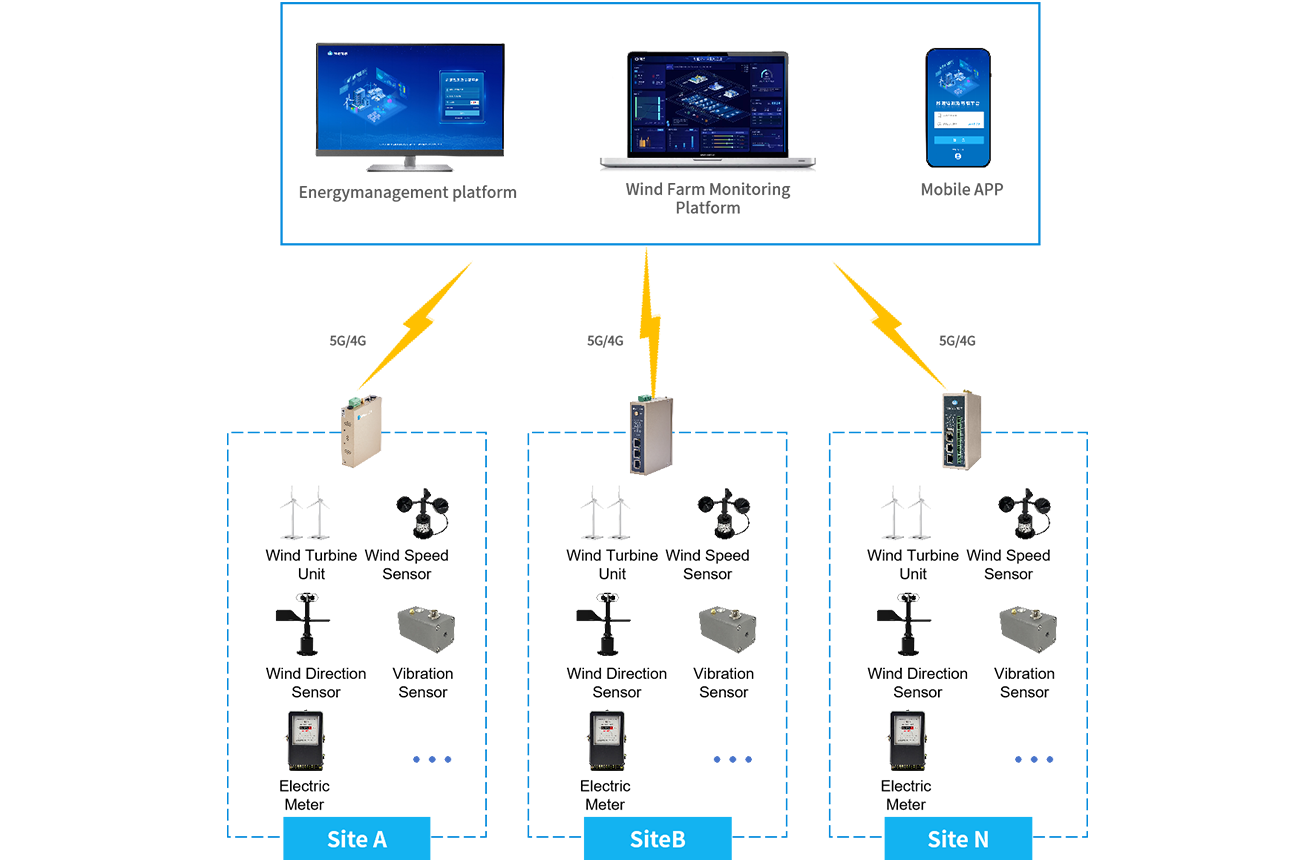

Through WideIOT's industrial smart gateway, data is collected from each wind turbine and associated equipment—including wind speed sensors, wind direction sensors, and vibration sensors—at the wind farm. The gathered operational data (such as rotational speed, power output, and temperature) is transmitted to the wind farm monitoring and management platform. The platform performs real-time data analysis to monitor turbine operational status. Upon detecting faults or anomalies, it promptly issues alerts while providing diagnostic insights and maintenance recommendations. It also supports remote control functions including turbine start/stop operations, parameter adjustments, and optimized power generation scheduling.

Wind Turbine Data Collection

Acquire detailed wind turbine operation data to provide a data foundation for wind farm management.

Operation Status Monitoring

Real-time understanding of wind turbine operation to ensure safe and stable operation of wind turbines.

Fault Diagnosis and Early Warning

Detect potential faults in advance to reduce downtime and maintenance costs.

Power Generation Performance Evaluation

Evaluate wind turbine power generation efficiency and optimize wind turbine configuration and operation strategies.

Remote Operation and Maintenance Management

Evaluate wind turbine power generation efficiency and optimize wind turbine configuration and operation strategies.

Optimized Dispatch and Management

Reasonably arrange wind turbine power generation to improve wind energy utilization efficiency and power generation benefits.

-

Industrial GateWay

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.

click to view detail>>

-

IOT Terminals

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.

click to view detail>>

-

Industrial Router

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.

click to view detail>>

-

NAT Coupler

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.

click to view detail>>

-

Software Platforms

click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>> WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>>

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>> WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>>

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>> The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>>

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>>

Go Top

Go Top