Water Treatment Plant Pump Station Monitoring

Improve Pump Station Operation Efficiency to Achieve Unattended Management

Pump Station Data Collection

Equipment Status Monitoring

Fault Early Warning and Handling

Energy Consumption Optimization and Control

Remote Dispatch and Management

Safety Protection and Guarantee

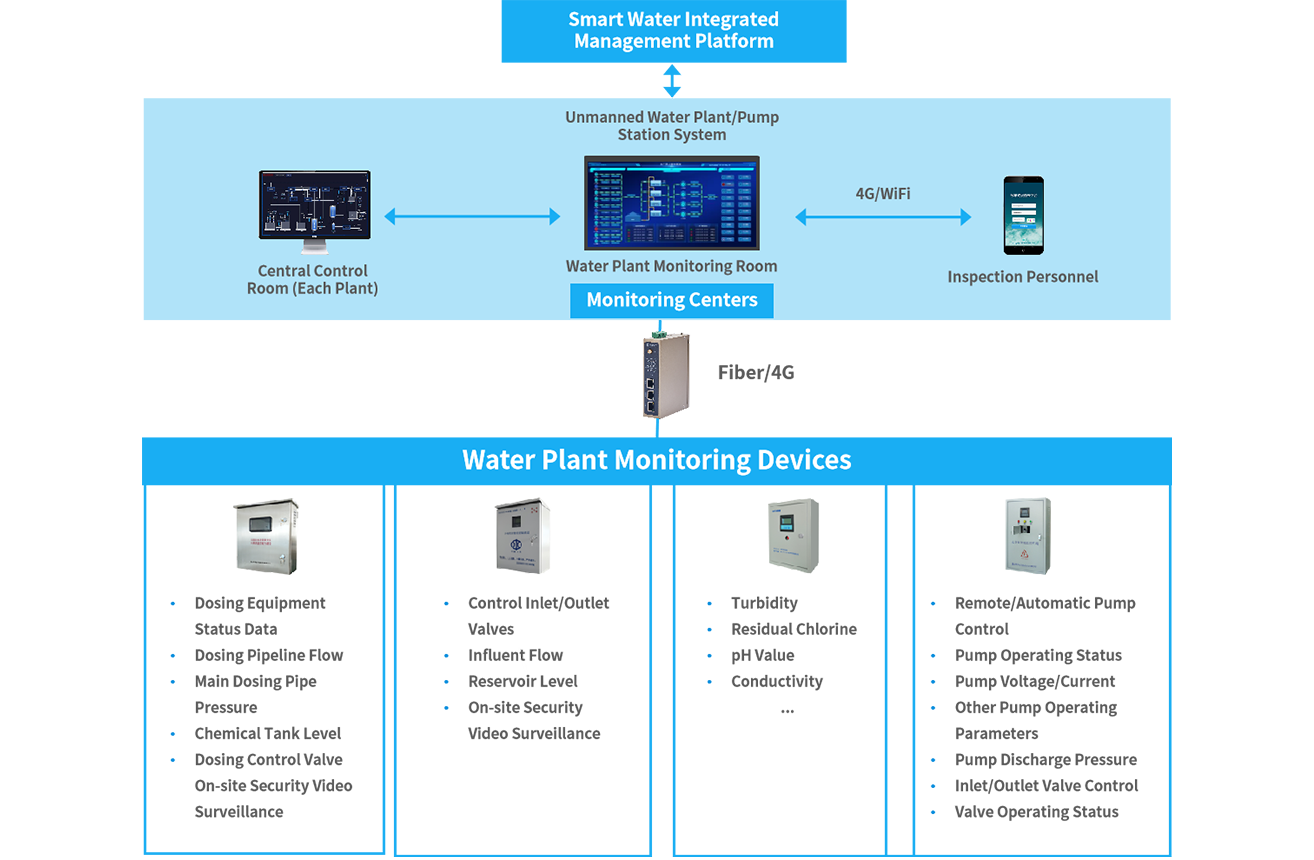

Pump stations are critical components of water supply systems, with their operational status directly impacting the stability and reliability of water delivery. Traditional pump station management relies on manual inspections and operations, resulting in low efficiency and difficulty in achieving real-time monitoring. With the advancement of automation technology, an advanced monitoring and management system is required to enhance pump station operational efficiency, reduce maintenance costs, and enable unmanned operation.

Through WideIOT's industrial smart gateway, operational data (such as running status, flow rate, pressure, and temperature) is collected from pump station equipment including water pumps, motors, and valves. This data is transmitted to the unmanned pump station monitoring management platform, where it undergoes real-time analysis and processing. When equipment anomalies or failures occur, the platform promptly issues alerts and provides diagnostic insights and troubleshooting recommendations. Simultaneously, the platform enables energy consumption optimization control and remote scheduling management based on water supply demands and equipment operation status. It incorporates comprehensive security protection mechanisms to ensure the safe operation of pump stations.

Pump Station Data Collection

Comprehensively and timely acquire pump station operation data to provide a basis for management and decision-making.

Equipment Status Monitoring

Real-time grasp of equipment operation status, detect potential faults in advance, and reduce equipment maintenance costs.

Fault Early Warning and Handling

Quickly respond to equipment faults, shorten fault processing time, and ensure stable water supply.

Energy Consumption Optimization and Control

Optimize energy consumption according to actual needs and reduce pump station operation costs.

Remote Dispatch and Management

Realize remote operation and dispatch, improve management efficiency, and achieve unattended management.

Safety Protection and Guarantee

Ensure the safe operation of the pump station and prevent illegal intrusion and data leakage.

-

Industrial GateWay

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.

click to view detail>>

-

IOT Terminals

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.

click to view detail>>

-

Industrial Router

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.

click to view detail>>

-

NAT Coupler

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.

click to view detail>>

-

IOT Data Platform

WideIOT·The IOT Data Platform( industrial equipment data platform )is a highly concurrent cloud platform for remote management and visualization of industrial equipment data, which is widely used in intelligent factory data acquisition middle platform, remote equipment operation management platform, Internet of Things data cloud platform in various industries, etc.

click to view detail>>

-

Equipment Remote Maintenance System

WideIOT Equipment Remote Maintenance System is a software and hardware system that realizes remote maintenance and operation of distributed equipment. Configuration, remote diagnostics, remote debugging and remote upgrade procedures.

click to view detail>>

-

Equipment Remote Access Platform

WideIOT·The equipment remote access cloud platform is a fast access platform for real-time monitoring of distributed equipment data, which adopts SAAS cloud service mode to establish real-time online data channels for the interconnection of various industrial equipment data at the industrial site.

click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>> WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>>

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>> WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>>

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>> The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>>

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>> WideIOT·The IOT Data Platform( industrial equipment data platform )is a highly concurrent cloud platform for remote management and visualization of industrial equipment data, which is widely used in intelligent factory data acquisition middle platform, remote equipment operation management platform, Internet of Things data cloud platform in various industries, etc.click to view detail>>

WideIOT·The IOT Data Platform( industrial equipment data platform )is a highly concurrent cloud platform for remote management and visualization of industrial equipment data, which is widely used in intelligent factory data acquisition middle platform, remote equipment operation management platform, Internet of Things data cloud platform in various industries, etc.click to view detail>> WideIOT Equipment Remote Maintenance System is a software and hardware system that realizes remote maintenance and operation of distributed equipment. Configuration, remote diagnostics, remote debugging and remote upgrade procedures.click to view detail>>

WideIOT Equipment Remote Maintenance System is a software and hardware system that realizes remote maintenance and operation of distributed equipment. Configuration, remote diagnostics, remote debugging and remote upgrade procedures.click to view detail>> WideIOT·The equipment remote access cloud platform is a fast access platform for real-time monitoring of distributed equipment data, which adopts SAAS cloud service mode to establish real-time online data channels for the interconnection of various industrial equipment data at the industrial site.click to view detail>>

WideIOT·The equipment remote access cloud platform is a fast access platform for real-time monitoring of distributed equipment data, which adopts SAAS cloud service mode to establish real-time online data channels for the interconnection of various industrial equipment data at the industrial site.click to view detail>>

Go Top

Go Top