Textile Machinery and Equipment

Optimize the Management of Textile Machinery and Equipment to Improve Production Efficiency

Data Collection

Remote Monitoring

Fault Alarm

Equipment Management

Operation and Maintenance Management

Data Analysis

Textile factories are equipped with a large number of mechanical devices. Traditional management modes make it difficult to grasp the real-time working status of equipment and adjust production schedules in a timely manner. When equipment malfunctions, it puts great demands on the professional skills of staff; delayed maintenance leads to high resource waste and cost expenditure, which seriously impacts order delivery.

Traditional equipment management methods can no longer meet the needs of modern production. There is an urgent need to obtain real-time equipment operation status and adjust production plans promptly, so a remote monitoring solution for textile machinery and equipment is imperative.

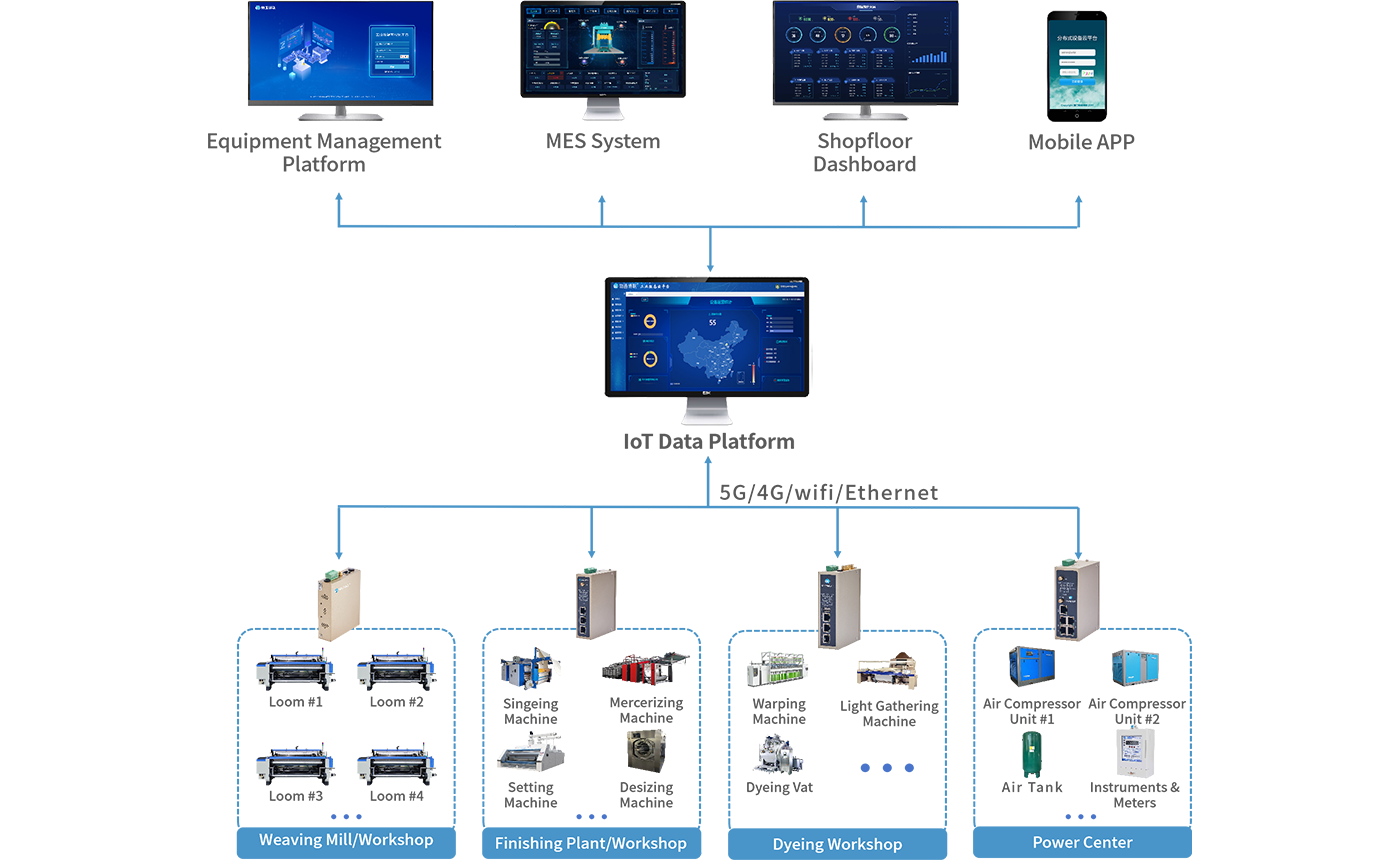

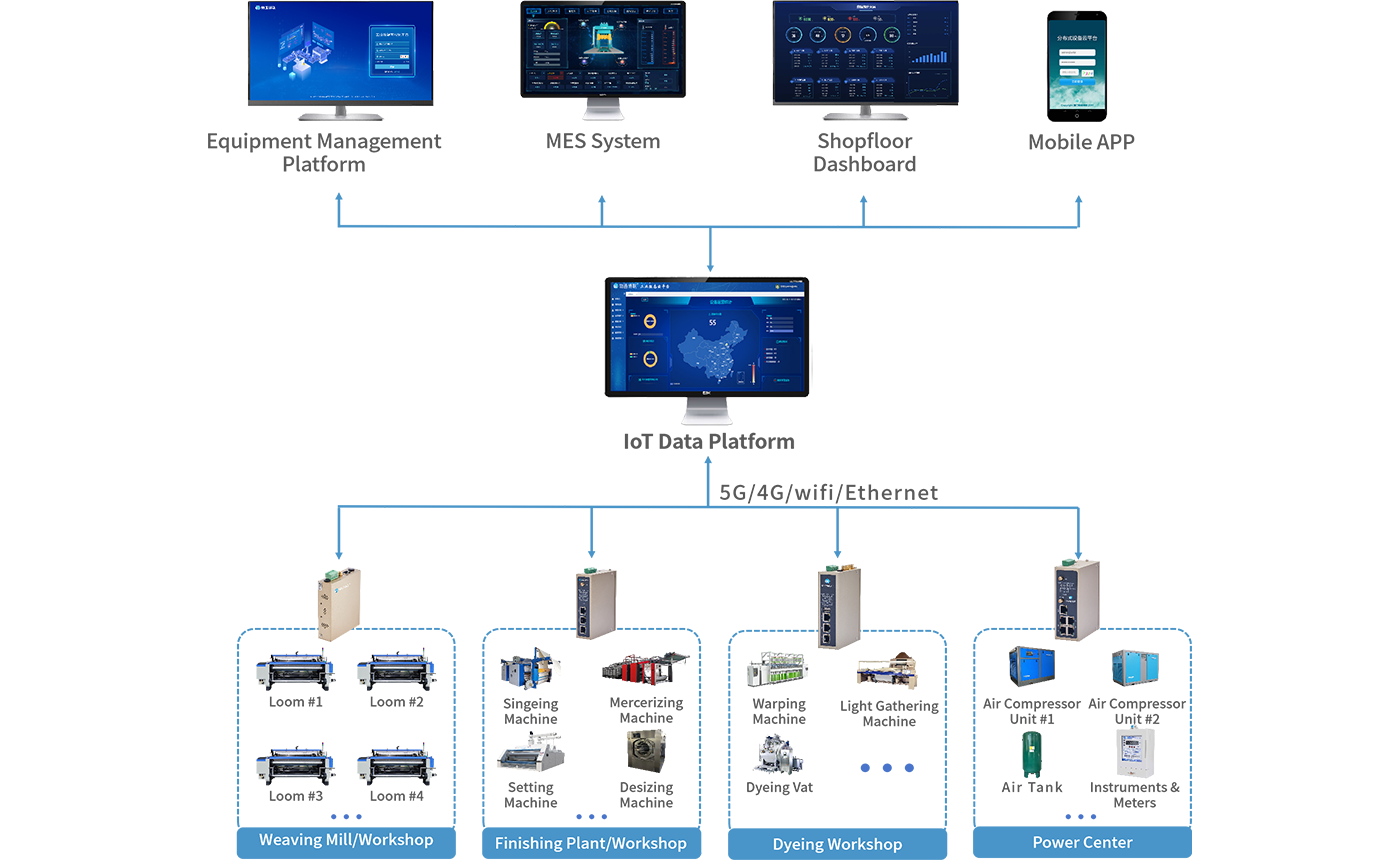

WideIOT has launched a textile factory equipment monitoring and operation and maintenance system solution based on PLC Internet of Things technology. The system connects to the PLC controllers of textile machinery via industrial intelligent gateways to collect data, and communicates in real time with the WideIOT equipment operation and maintenance management platform through 5G/4G, WiFi, Ethernet and other means, providing efficient and convenient management tools for equipment management and operation and maintenance management. The gateway can also forward data to the MES system, and analyze various equipment statuses and production parameters in conjunction with data dashboards, thereby helping to formulate scientific and reasonable business strategies and facilitating the digital transformation of textile factories.

Data Collection

The gateway is equipped with powerful intelligent data collection capabilities. It can collect equipment operation status and operating parameters such as voltage, current, temperature, pressure and other data, and transmit them to the Wutong Bolian IOT data middle platform or the factory upper computer in real time.

Remote Monitoring

Remotely view production line equipment operation status, process parameters, alarm events, camera data and other information through mobile phones and computers, improving work flexibility.

Fault Alarm

By setting alarm rules, automatic alarms are triggered when abnormal equipment data or faults are detected. Notifications are sent to managers and maintenance personnel via WeChat, SMS, email, etc., enabling quick location, diagnosis and measures to reduce unexpected equipment downtime.

Equipment Management

Manage the equipment connected to the system in each workshop and production line, establish equipment files, and check information such as equipment type, purchase time, and maintenance date at any time.

Operation and Maintenance Management

Equipment faults automatically generate maintenance work orders. Users can create, claim, submit and view operation and maintenance work order logs, track the progress of work order execution and intervene in a timely manner, realizing visualization of the operation and maintenance process.

Data Analysis

Summarize and analyze equipment operation status, real-time data, historical data, alarm data and operation and maintenance data. Realize intelligent analysis of OEE data, output information, equipment utilization rate, etc., to help enterprises make scientific and reasonable decisions.

-

Industrial GateWay

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.

click to view detail>>

-

IOT Terminals

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.

click to view detail>>

-

Industrial Router

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.

click to view detail>>

-

NAT Coupler

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.

click to view detail>>

-

Software Platforms

click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>> WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>>

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>> WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>>

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>> The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>>

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>>

Go Top

Go Top