Reservoir Water Level and Dam Safety

Achieve Unattended Safe Operation of Reservoir Dams

Real-time Monitoring

Map Display

Overlimit Alarm

Interconnection and Sharing

Station Management

Data Analysis

In recent years, influenced by global climate change and human activities, the frequency and intensity of extreme weather events have increased, imposing new and higher demands on the safe operation of reservoir engineering. Therefore, establishing a reservoir rainfall and water level monitoring and dam safety early warning system enables comprehensive control over reservoirs and dams. This system provides reliable data support for flood control, disaster mitigation, peak shaving, and dry-season water supply, ensuring the safe and stable operation of water conservancy facilities.

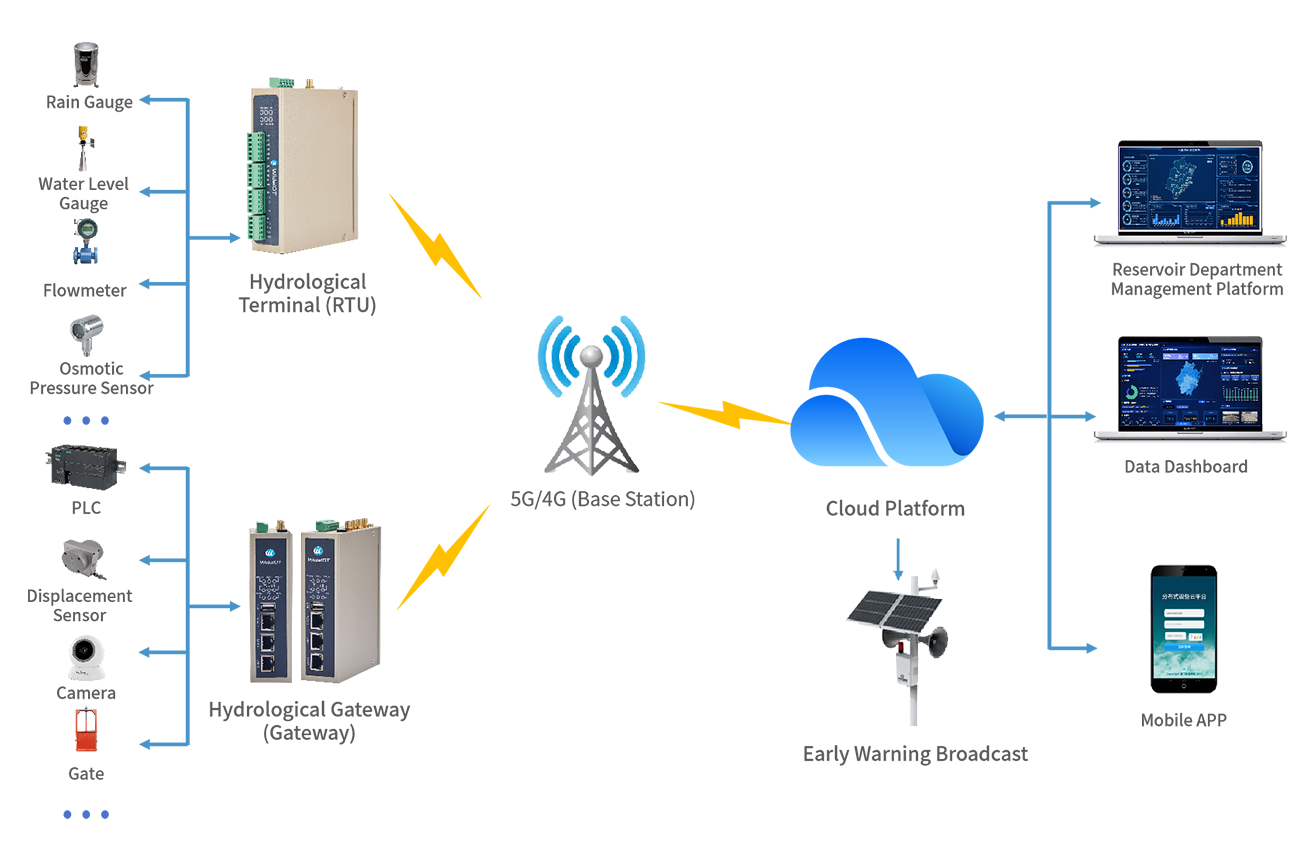

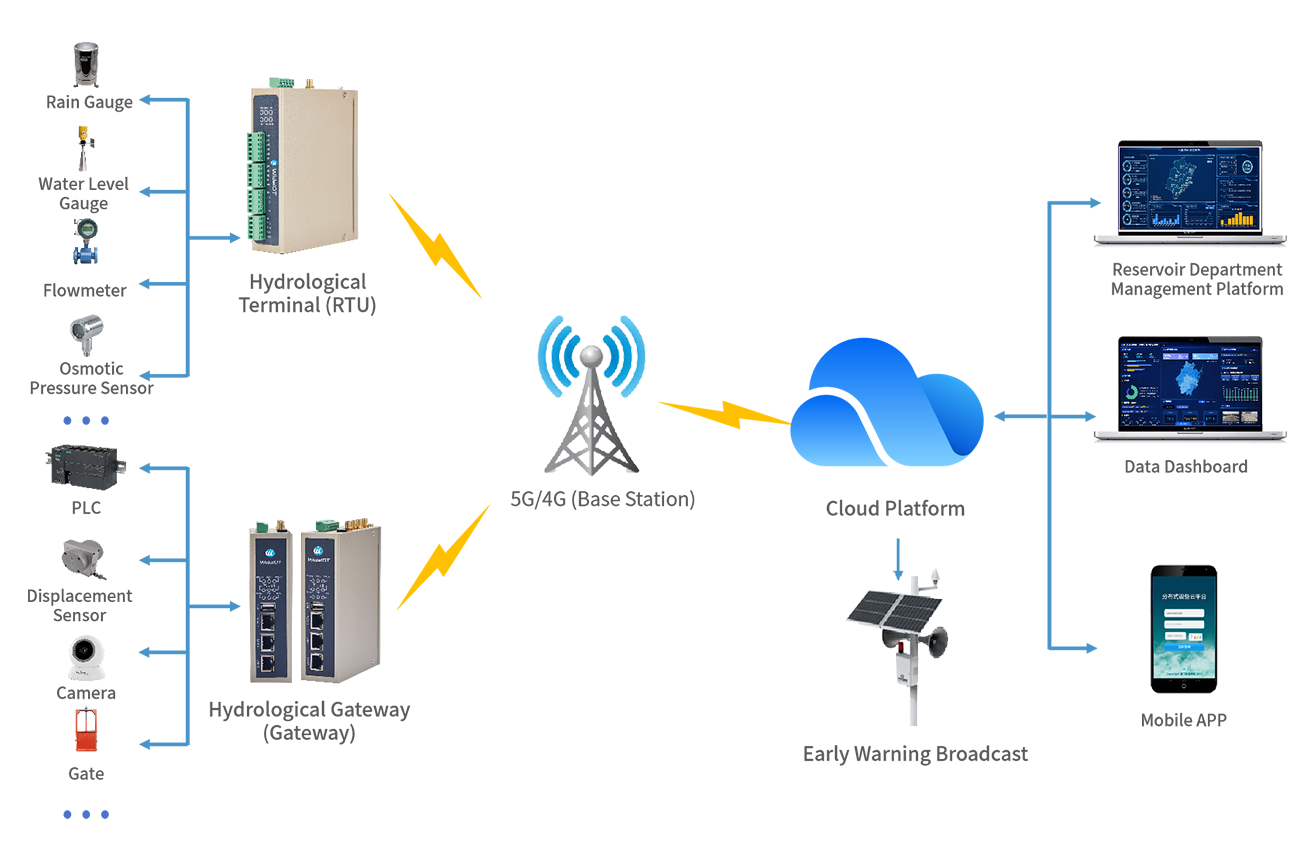

Reasonably deploy flow meters, water level gauges, rain gauges, seepage sensors, piezometers, displacement sensors, and cameras at the reservoir dam. These devices connect to the WideIOT Hydrology Gateway (RTU) and transmit data in real time via 5G/4G networks to the reservoir management platform. This enables remote monitoring and automatic alerts, prompting relevant departments to take measures to maintain dam safety. Data reports and graphs are used to assess flood risks and severity, enabling macro-level regulation of watershed water resource allocation to safeguard the lives and property of residents surrounding the reservoir.

Real-time Monitoring

Keep abreast of changes in reservoir hydrological data and real-time video images through mobile phones, PCs, data dashboards, etc. Quickly grasp key information such as pore water pressure inside the reservoir dam, water level in the reservoir, inflow and outflow discharge of the reservoir, rainfall, and dam displacement.

Map Display

Realize real-time display and query of GIS electronic maps, including equipment statistics, location distribution, operating status, monitoring data, and alarm information of each station, to comprehensively overview the operating status of the reservoir dam.

Overlimit Alarm

Automatically alarm for abnormalities such as equipment failures, excessive instantaneous flow, and dam displacement. Users can receive alarm information via WeChat, SMS, email, etc., to quickly locate, diagnose and take measures to avoid accidents.

Interconnection and Sharing

Establish a unified standard data exchange and sharing system to realize the interconnection and sharing of safety monitoring information of reservoir dams across the province. Horizontally, it connects with meteorological, hydrological, flood control and other platforms; vertically, it realizes synchronous collection and sharing at the ministerial, provincial, municipal and county levels.

Station Management

Unify the basic information, equipment information and management information of monitoring stations into the system management. Query equipment operating status, working parameters, maintenance cycles and other information at any time to form a visual and efficient operation and maintenance process.

Data Analysis

Conduct comparative analysis of historical data such as dam phreatic line, reservoir water level, real-time rainfall, dam seepage flow and dam displacement. Combine management experience with big data models to comprehensively judge the safety risks of reservoir dams and make scientific and reasonable decisions.

-

Industrial GateWay

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.

click to view detail>>

-

IOT Terminals

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.

click to view detail>>

-

Industrial Router

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.

click to view detail>>

-

NAT Coupler

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.

click to view detail>>

-

Software Platforms

click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>> WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>>

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>> WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>>

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>> The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>>

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>>

Go Top

Go Top