-

Pollution Monitoring and Management System Solution for the Pharmaceutical & Chemical Industry

2026-01-16 15:48:14

Industry Background

As global attention to environmental protection intensifies and international environmental regulations (such as REACH, EPA standards, and EU Industrial Emissions Directive) become increasingly stringent, the pharmaceutical and chemical industry—typically characterized by high pollution and energy consumption—faces unprecedented environmental challenges. During production processes, the industry generates a wide range of pollutants including waste gas, wastewater, and solid waste, many of which are highly toxic and difficult to treat. Traditional manual monitoring and extensive management models can no longer meet the requirements for real-time, accurate, and efficient environmental supervision in the global market.

Driven by the global trend toward green and sustainable development, transitioning environmental governance in the pharmaceutical and chemical industry to refined and intelligent management has become an inevitable choice for enterprises to achieve high-quality development, ensure compliance with international standards, and enhance their global competitiveness.

Pain Point Analysis

01 Decentralized Monitoring Equipment Management

Pollution monitoring devices are often scattered and operate independently without networked collaboration. Reliance on manual inspections for data recording results in heavy workloads, low efficiency, data lag, and significant errors, making it difficult to grasp real-time dynamics of pollutant emissions.02 Inefficient Emergency Response

Current emergency responses to environmental incidents rely on manual reporting, lacking intelligent over-limit early warning and traceability mechanisms. This leads to low disposal efficiency, potential compliance risks, and may result in the escalation of environmental accidents and damage to corporate reputation.03 Isolated Data Management

Data related to wastewater, waste gas, and solid waste is scattered across different systems, forming "information silos." This prevents linked analysis and traceability verification of data, making it challenging to meet the requirements of frequent and unplanned environmental audits.Solution

WideIOT offers an intelligent pollution monitoring and management system centered on "environmental data acquisition gateways + cloud-based monitoring platforms." By connecting various environmental monitoring devices—such as waste gas sensors, water quality monitors, and weighing instruments—to WideIOT’s industrial-grade environmental data acquisition gateways, the system realizes real-time data collection of:- Waste gas emissions (e.g., VOCs, particulate matter, sulfur dioxide)

- Wastewater discharge (e.g., flow rate, pH value, COD, ammonia nitrogen)

- Solid waste generation (e.g., production volume, generation time)

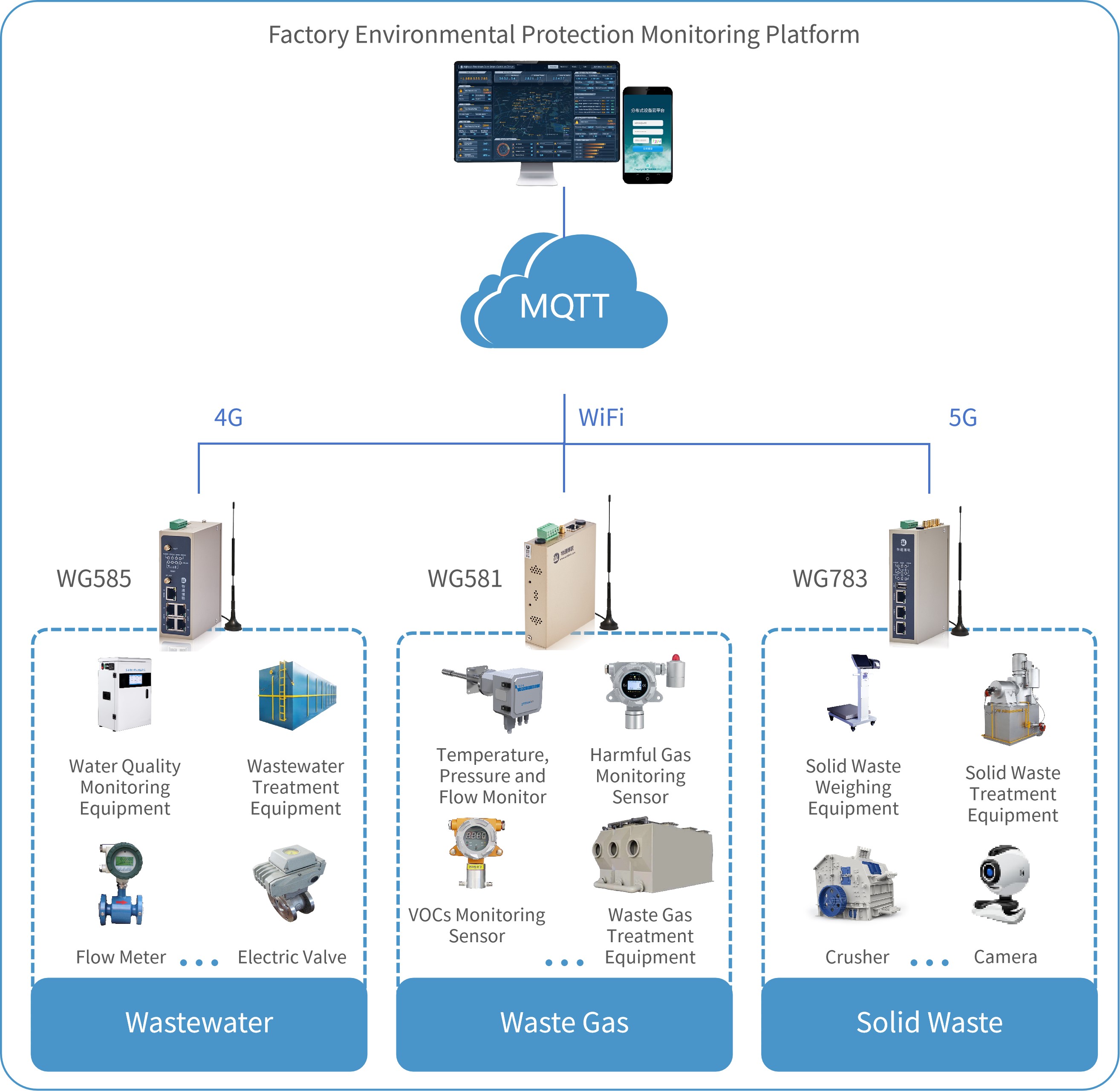

System Architecture

- Peripheral Monitoring Devices: Waste gas sensors (VOCs, harmful gases), water quality monitors, flow meters, solid waste weighing equipment, crushers, wastewater treatment equipment, waste gas treatment equipment, cameras, electric valves, temperature/pressure/flow monitors.

- Core Gateway: WideIOT Industrial-Grade Environmental Data Acquisition Gateways (WG581, WG585, WG783)

- Communication Protocols & Methods: MQTT, 5G/4G/WiFi/Ethernet

- Central Platform: Enterprise Environmental Monitoring Cloud Platform

Core Functions

01 Comprehensive Data Acquisition

The gateways are equipped with multiple serial ports and network interfaces, supporting seamless connection to various environmental monitoring instruments and sensors. They collect real-time data on pollutant emissions, including concentration, type, and discharge time, ensuring full coverage of key environmental indicators.02 Secure & Stable Data Transmission

Adopting an industrial-grade design, the gateways are suitable for harsh and complex working environments. They support breakpoint resume transmission and multi-network redundancy to ensure no data loss. Remote configuration, diagnosis, and firmware upgrades are also available, greatly reducing on-site maintenance costs and complexity.03 Intelligent Over-Limit Alerts

Safety thresholds for waste gas, wastewater, and solid waste are preset in the system. When data exceeds these limits, the system automatically notifies managers via WeChat, SMS, or email, highlighting alarm details and abnormal data to enable rapid diagnosis and control.04 Compliant Data Reporting

The system realizes real-time communication with the enterprise’s internal environmental supervision system and databases. It supports standardized data reporting to meet international environmental audit requirements, reducing manual costs associated with equipment meter reading and data entry.05 Remote Equipment O&M

By connecting to the PLC of treatment equipment, the system achieves centralized management of core information such as monitoring point distribution, pollutant emission volume and concentration, operation status of treatment equipment, alarm statistics, and compliance rates. Remote control of equipment is also supported.06 Data Analysis & Application

Managers can quickly generate various data reports, such as daily/weekly/monthly pollutant emission reports and alarm statistics reports. These reports provide comprehensive data support for environmental inspections, process optimization, and business strategy formulation, enabling scientific and rational decision-making.Solution Benefits

- Real-Time & Accurate Monitoring: Achieve 24/7 real-time monitoring of pollutants, eliminating data lag and errors caused by manual operations, and ensuring full visibility of environmental performance.

- Enhanced Compliance & Risk Mitigation: Proactively meet international environmental regulations, reduce compliance risks, and avoid penalties or reputational damage from environmental incidents.

- Efficient Operation & Cost Reduction: Automate data collection, reporting, and alarm processes, reducing manual workloads and operational costs. Remote O&M further minimizes on-site maintenance expenses.

- Sustainable Development Support: Provide data-driven insights for process optimization, helping enterprises reduce pollutant emissions, improve resource utilization efficiency, and transition toward green and sustainable operations in line with global ESG (Environmental, Social, Governance) trends.

Previous:Nothing

Go Top

Go Top