Against the backdrop of global carbon neutrality goals and the accelerating green transition in the shipping industry, new energy electric vessels have become the core choice for short-haul, high-frequency shipping scenarios — including cargo transportation, passenger ferries, and port operations. However, international maritime regulations (such as battery-powered vessel operation standards) mandate real-time monitoring of operational status and battery parameters, abnormal alarm capabilities, and standardized data exchange. Key challenges such as scattered mobile vessels, complex marine environments, and disorganized equipment maintenance have become barriers to regulatory compliance and efficient operations for enterprises worldwide.

WideIOT addresses these industry pain points with a comprehensive digital solution built on Industrial Intelligent Gateways, delivering end-to-end connectivity for new energy electric vessels. Our solution lays a solid foundation for safe, efficient, and green shipping through full-lifecycle digital capabilities.

Critical Industry Challenges

- Need for Remote Monitoring & Centralized Management: Vessels operate in mobile and scattered environments, lacking unified data collection and networking for core equipment such as motors and Battery Management Systems (BMS). Faults are often detected too late, posing significant safety risks. Real-time remote monitoring, centralized management, and tracking of vessel location and equipment status are therefore urgent priorities.

- Demand for Standardized Maintenance Systems: Current maintenance workflows lack standardized processes, leading to disorganized data that is not effectively analyzed or utilized. This results in unscientific maintenance plans, inefficient resource allocation, and increased operational costs. Establishing online, standardized maintenance management systems is crucial to improving efficiency and reducing expenses.

- Reliable Data Collection & Communication Requirements: Vessels navigating marine environments are highly susceptible to weather, hydrological conditions, and traffic disruptions, which can cause communication failures. Data collection equipment must deliver reliable performance and ensure data integrity, enabling traceability, statistics, and in-depth analysis.

WideIOT's End-to-End IoT Solution

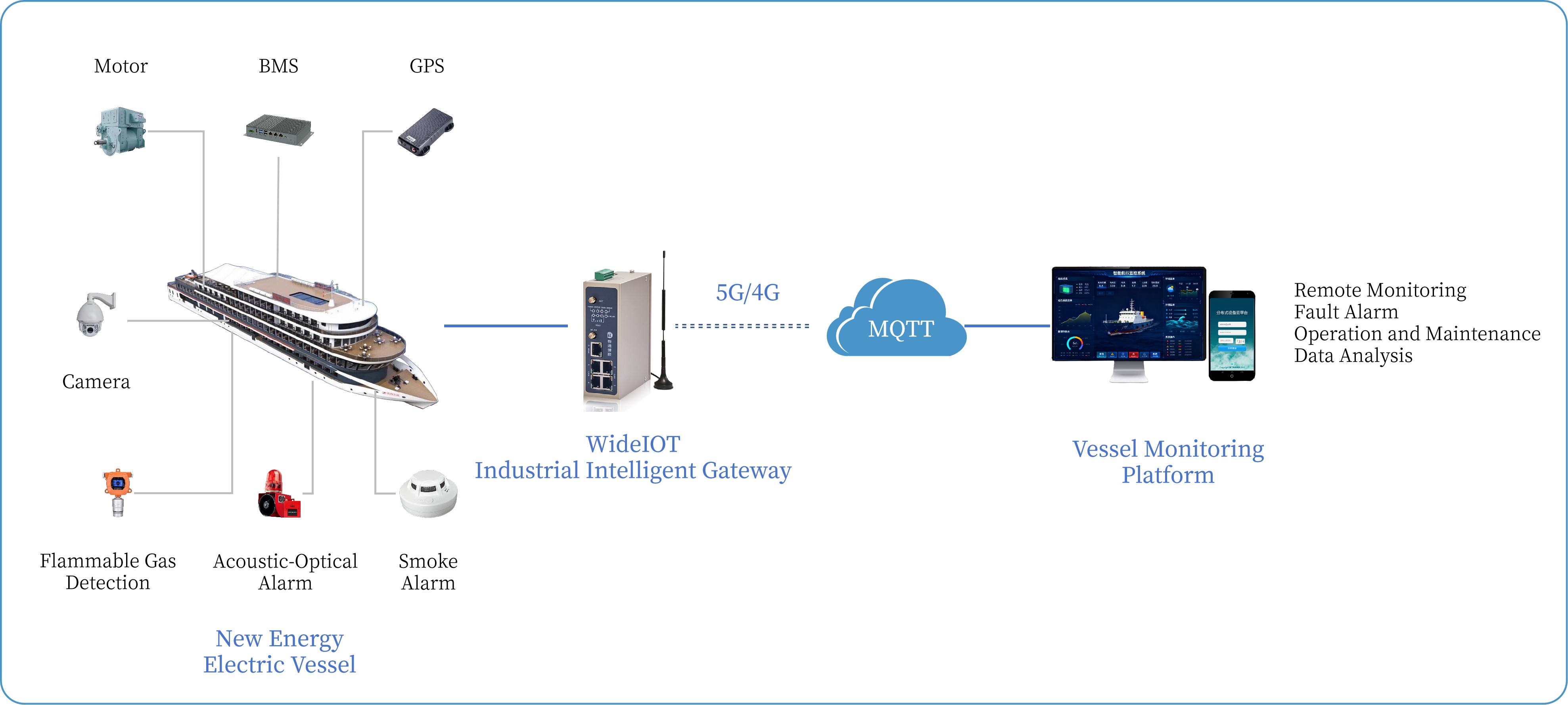

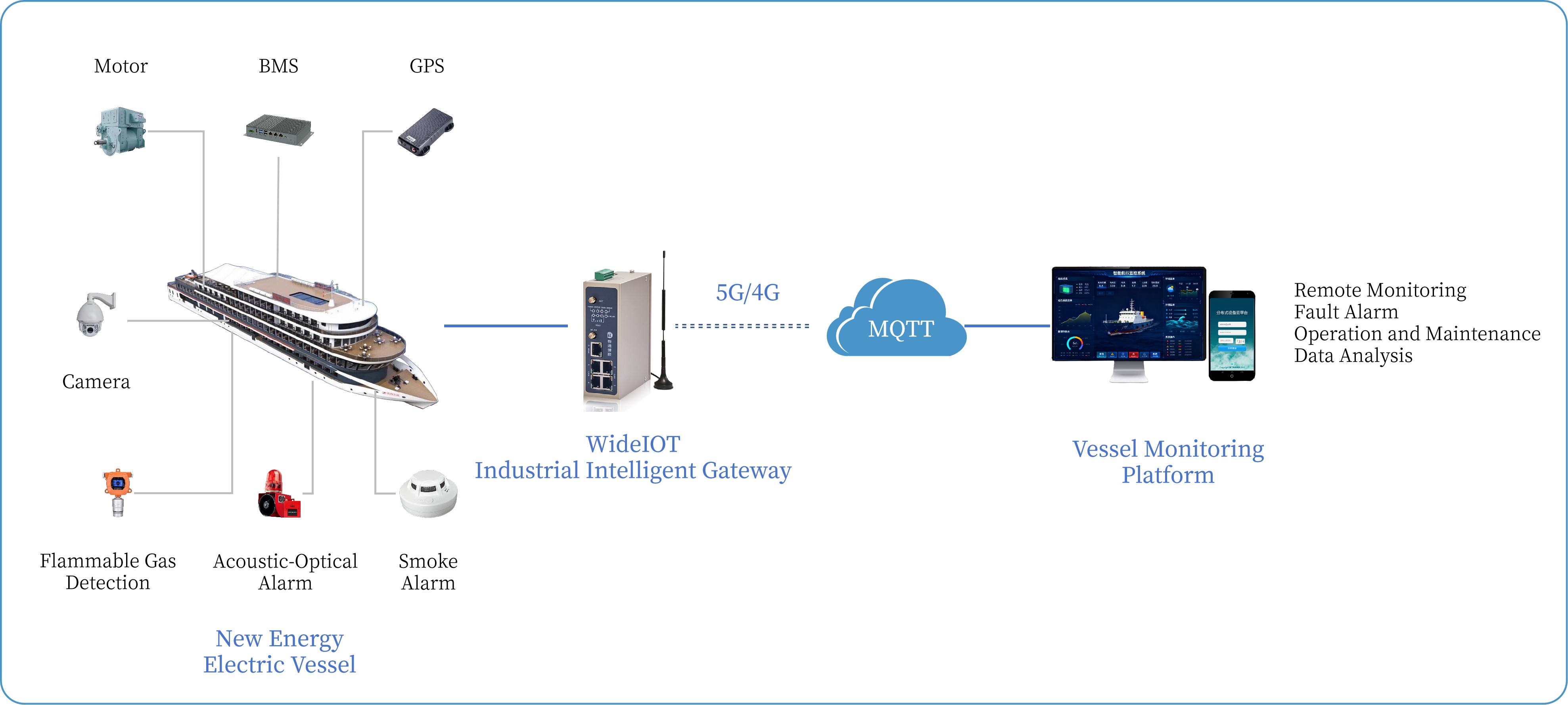

WideIOT’s integrated solution follows a "Terminal Collection → Stable Transmission → Cloud Control → Intelligent Decision-Making" framework, with Industrial Intelligent Gateways as the core hub. This hardware-software ecosystem bridges the digital gap between vessel equipment and management platforms, achieving the transformation goals of "safe control, efficient maintenance, and actionable data."

Core Architecture

- Industrial Intelligent Gateway: Serves as the central data hub with multiple communication interfaces (serial ports, Ethernet ports) compatible with protocols for motors, BMS, and other marine equipment. It seamlessly collects full-dimensional data including vessel GPS location, key motor operating parameters, and critical battery metrics.

- Marine Monitoring & Management Platform: Cloud-based platform that integrates data transmitted via 5G/4G networks. It enables remote monitoring, fault alerts, maintenance management, and data analytics to drive operational excellence.

- Reliability Enhancements: Equipped with multi-network redundancy and breakpoint resume technology. The gateway caches data locally during communication outages (due to complex marine conditions) and automatically syncs it to the cloud once connectivity is restored, ensuring complete, consistent data.

Key Features

1. Comprehensive Data Collection

Captures real-time data on vessel positioning, motor performance, and battery health (e.g., voltage, temperature, state of charge). This provides a data foundation for safety monitoring and operational visibility.

2. Standardized Data Cloud Transmission

Supports standard protocols such as HTTP and MQTT, enabling real-time data sharing with marine monitoring platforms, classification society verification systems, and third-party tools. Ensures compliance with international regulations and cross-system data interoperability.

3. Highly Reliable Data Assurance

Dual protection through multi-network redundancy and breakpoint resume technology eliminates data loss risks caused by unstable marine communication. Guarantees data integrity, consistency, and timeliness for traceability and analysis.

4. Remote Intelligent Control

Enables cloud-based device monitoring, configuration, debugging, diagnostics, and firmware updates. Breaks geographical barriers, reduces on-board maintenance frequency, and improves management efficiency while cutting costs.

5. Precise Fault Alerts

Customizable alarm thresholds trigger instant notifications via WeChat, SMS, or email when anomalies occur. Alerts include detailed information on faulty equipment, parameters, and timestamps, enabling rapid diagnosis and minimizing downtime.

6. Full-Lifecycle Vessel Management

Visualizes vessel profiles, real-time location, motor/battery data, alarm history, and maintenance records on a unified platform. Establishes standardized vessel archives for traceable data and optimized resource allocation.

7. Standardized Closed-Loop Maintenance

Streamlines maintenance workflows with digital work orders covering inspections, repairs, and battery maintenance. Tracks task progress, responsible personnel, and work logs to ensure end-to-end accountability and improve maintenance standardization.

8. Data-Driven Decision-Making

Analyzes multi-dimensional reports (operational data, alarm statistics, maintenance records) to support scientific decision-making. Optimizes route planning, maintenance resource allocation, equipment R&D, and service quality for sustainable business growth.

Core Benefits for Global Clients

- Enhanced Regulatory Compliance: Meets international maritime standards for real-time monitoring, data exchange, and safety alerts, ensuring seamless compliance with regional and global regulations.

- Improved Operational Efficiency: Centralized remote management of multiple vessels eliminates manual on-site inspections, reducing labor costs and improving response times.

- Cost Reduction: Standardized maintenance processes and data-driven resource allocation lower operational and maintenance expenses, while reliable data transmission minimizes downtime losses.

- Strengthened Safety: Proactive fault detection and real-time monitoring of critical systems (motors, BMS) mitigate safety risks in complex marine environments.

- Sustainable Competitiveness: Supports green shipping initiatives and carbon neutrality goals, helping enterprises gain a competitive edge in the fast-growing low-carbon maritime market.

Global Applicability & Value

WideIOT’s solution is designed to adapt to diverse international maritime environments and regulatory frameworks, with compatibility for global communication standards (5G/4G, MQTT, HTTP) and multi-language platform support. It has been successfully deployed in passenger ferries, cargo ships, port workboats, and other electric vessel types across Asia, Europe, and Southeast Asia.

Beyond immediate operational gains, our solution empowers enterprises to build a smart, sustainable shipping ecosystem — enhancing ESG performance and aligning with global efforts to reduce maritime carbon emissions. Whether you’re a shipping operator aiming to optimize fleet efficiency or a vessel manufacturer seeking compliance-ready technology, WideIOT delivers a scalable, future-proof solution for the new era of green maritime transportation.

Partner with WideIOT to navigate the green shipping transition with confidence — where safety, efficiency, and sustainability converge.

Against the backdrop of global carbon neutrality goals and the accelerating green transition in the shipping industry, new energy electric vessels have become the core choice for short-haul, high-frequency shipping scenarios — including cargo transportation, passenger ferries, and port operations. However, international maritime regulations (such as battery-powered vessel operation standards) mandate real-time monitoring of operational status and battery parameters, abnormal alarm capabilities, and standardized data exchange. Key challenges such as scattered mobile vessels, complex marine environments, and disorganized equipment maintenance have become barriers to regulatory compliance and efficient operations for enterprises worldwide.WideIOT addresses these industry pain points with a comprehensive digital solution built on Industrial Intelligent Gateways, delivering end-to-end connectivity for new energy electric vessels. Our solution lays a solid foundation for safe, efficient, and green shipping through full-lifecycle digital capabilities.

Against the backdrop of global carbon neutrality goals and the accelerating green transition in the shipping industry, new energy electric vessels have become the core choice for short-haul, high-frequency shipping scenarios — including cargo transportation, passenger ferries, and port operations. However, international maritime regulations (such as battery-powered vessel operation standards) mandate real-time monitoring of operational status and battery parameters, abnormal alarm capabilities, and standardized data exchange. Key challenges such as scattered mobile vessels, complex marine environments, and disorganized equipment maintenance have become barriers to regulatory compliance and efficient operations for enterprises worldwide.WideIOT addresses these industry pain points with a comprehensive digital solution built on Industrial Intelligent Gateways, delivering end-to-end connectivity for new energy electric vessels. Our solution lays a solid foundation for safe, efficient, and green shipping through full-lifecycle digital capabilities.

Go Top

Go Top