Factory Security Monitoring

Ensure Factory Production Safety and Prevent Accidents

Real-time Video Surveillance

Environmental Parameter Monitoring

Potential Safety Hazard Early Warning

Emergency Response

Data Storage and Analysis

Safety Compliance Support

Various safety risks exist in factory production processes, such as fire, explosion, and mechanical injury. Traditional safety monitoring methods often suffer from limited coverage and slow response times, making it difficult to effectively prevent and respond to safety incidents. To ensure the safety of factory personnel and equipment while enhancing production safety, a comprehensive and efficient safety monitoring solution is required.

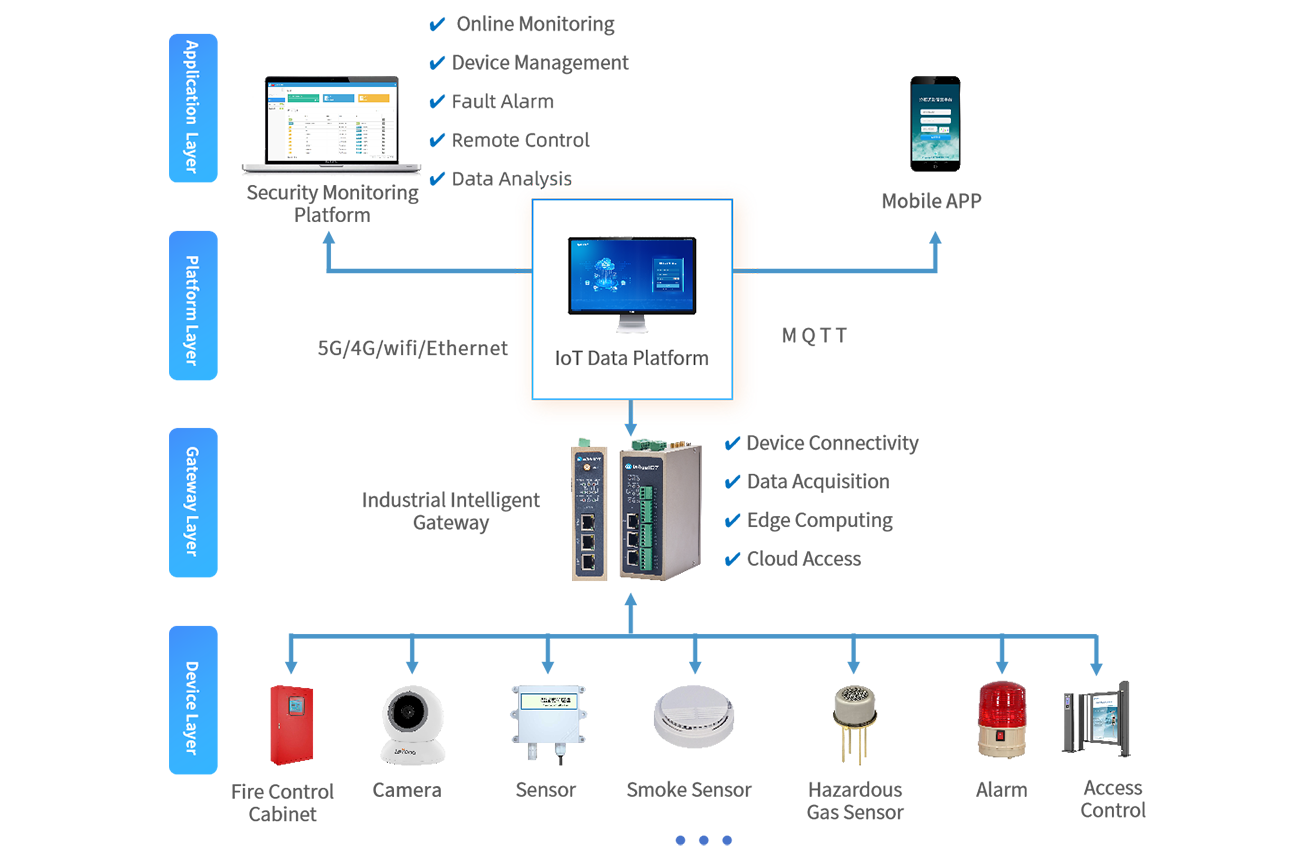

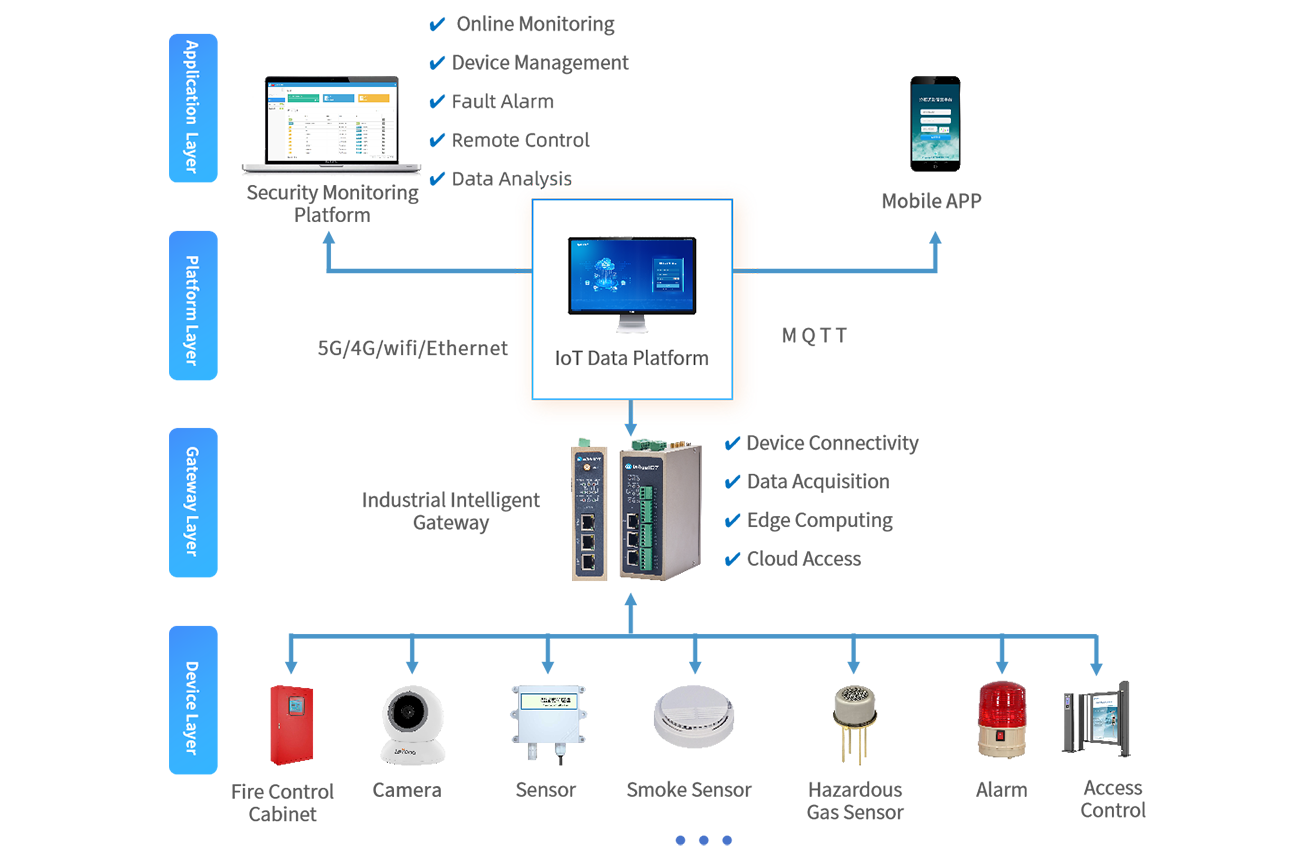

WideIOT connects production equipment, sensors, cameras, firefighting equipment, security systems, it integrates video surveillance, personnel behavior, and equipment status data for unified management and application. This enables real-time monitoring of factory environmental risks, non-compliant personnel behavior, safety attire violations, and unauthorized vehicle/personnel access. The system automatically triggers alerts, reports incidents, and coordinates emergency response commands, effectively addressing traditional challenges such as high oversight complexity, manual inspection oversights, weak preemptive prevention capabilities, and slow response times. This establishes a smart factory safety supervision solution to reduce the occurrence of safety incidents.

Real-time Video Surveillance

Provide full-range and non-blind-spot monitoring of factory production areas to timely detect and address potential safety hazards, effectively preventing safety accidents.

Environmental Parameter Monitoring

Real-time monitor environmental parameters (such as temperature, humidity, gas concentration, etc.) to mitigate environment-related safety risks.

Potential Safety Hazard Early Warning

Through intelligent alarms, identify potential safety hazards in advance and notify relevant personnel to take corresponding measures, ensuring the safety of equipment and personnel.

Emergency Response

In emergency situations, quickly activate the emergency response mechanism, link with fire protection, security and other equipment to handle emergencies promptly and minimize accident losses.

Data Storage and Analysis

Provide historical data and analysis reports for safety management, helping relevant personnel make more timely and accurate decisions and continuously improve safety management standards.

Safety Compliance Support

Through recording and reporting functions, factories can demonstrate compliance and present relevant data during audits and inspections, reducing legal and financial risks caused by non-compliance.

-

Industrial GateWay

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.

click to view detail>>

-

IOT Terminals

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.

click to view detail>>

-

Industrial Router

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.

click to view detail>>

-

NAT Coupler

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.

click to view detail>>

-

Software Platforms

click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>> WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>>

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>> WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>>

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>> The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>>

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>>

Go Top

Go Top