Factory Energy Management

Optimize Energy Usage and Reduce Energy Consumption Costss

Energy Data Collection

Energy Consumption Analysis

Energy Usage Strategy Optimization

Energy Cost Accounting

Energy Performance Evaluation

Energy Early Warning and Control

With the continuous rise in energy costs and increasingly stringent environmental regulations, factories are paying more and more attention to energy management. Traditional energy management methods lack real-time performance and refinement, failing to meet factories' needs for energy efficiency and cost control. Therefore, an advanced energy management solution is required to achieve rational energy utilization and effective cost control.

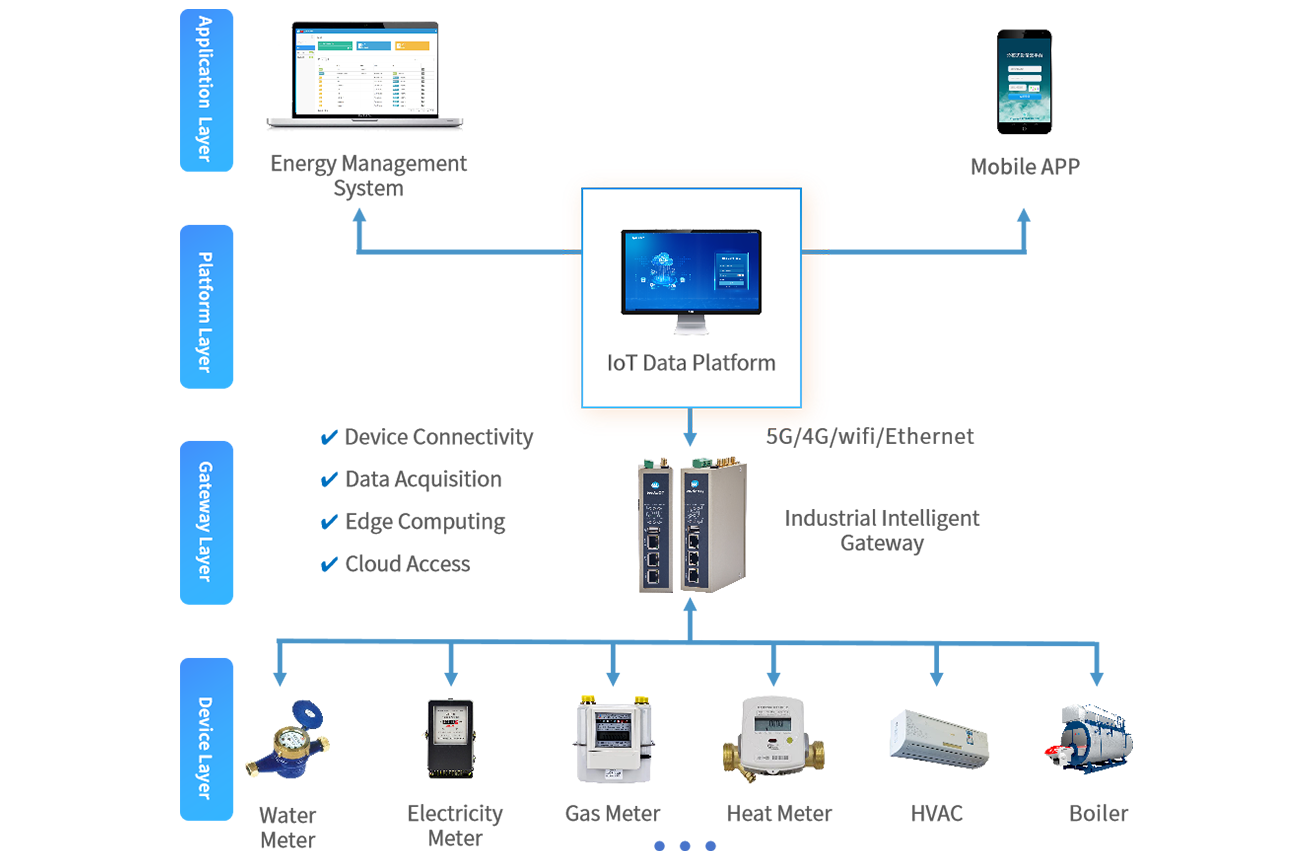

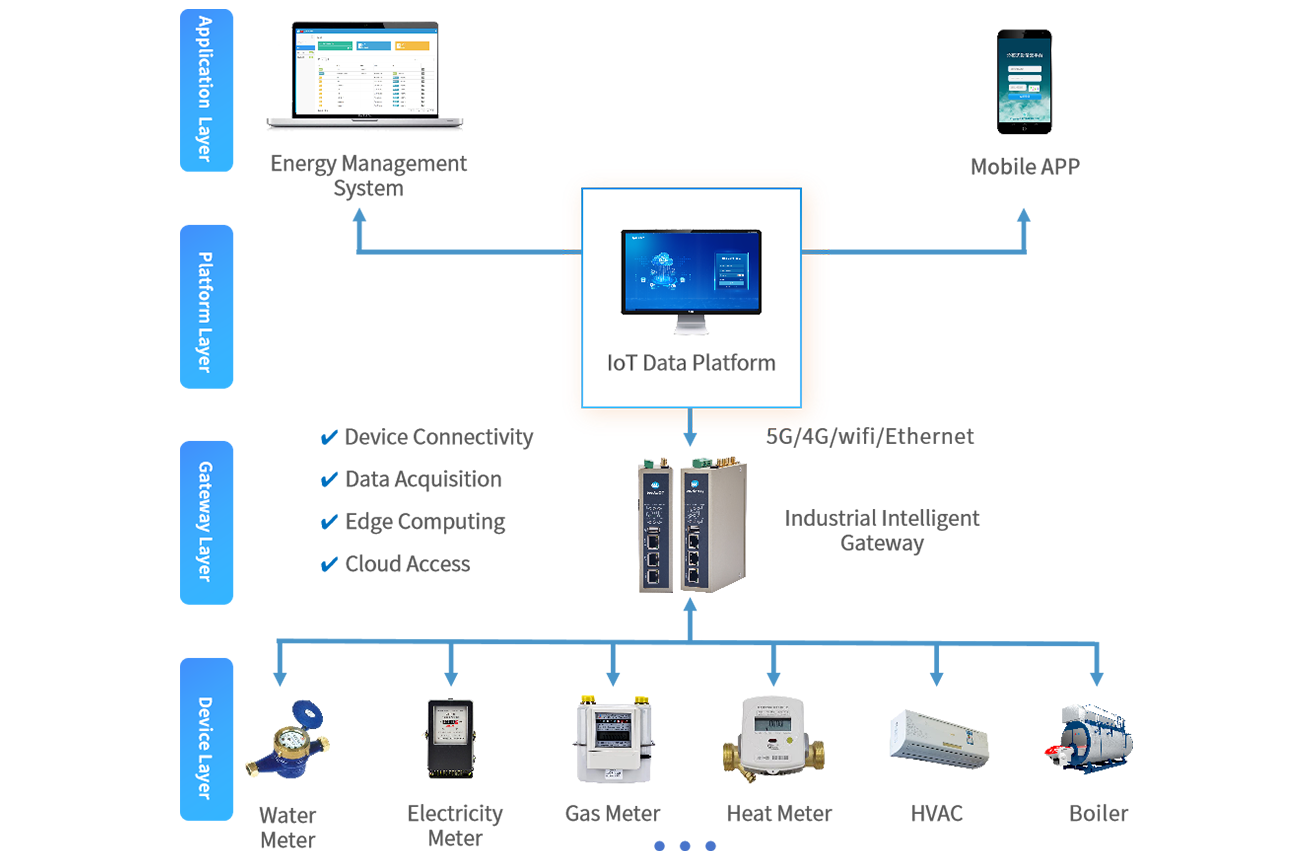

WideIOT Factory Energy Management Solution collects data from factory energy-consuming equipment to provide real-time monitoring of energy usage, alarms, and other conditions at various points in the factory. It helps factories establish an efficient energy consumption monitoring and management system to comprehensively manage energy data, timely identify and resolve energy waste issues. The solution enables peak load shifting for factories, improves energy utilization efficiency, and reduces enterprise operating costs. By mining data value, it provides data support for enterprises' energy-saving decisions and operational decisions.

Energy Data Collection

Through functions such as data visualization and remote monitoring, it enables real-time grasp of factory energy consumption and improves management flexibility and efficiency.

Energy Consumption Analysis

Conduct in-depth analysis of energy consumption structure and trends, research energy conversion efficiency and energy efficiency improvement plans, explore energy-saving potential, and reduce energy consumption.

Energy Usage Optimization

Implement intelligent analysis, intelligent diagnosis, and real-time energy-saving optimization. Construct targeted and operable energy-saving countermeasures and establish scientific energy-saving plans to achieve energy conservation and consumption reduction.

Energy Cost Accounting

Accurately calculate energy costs to provide a basis for cost control, ensuring enterprises set reasonable energy-saving and carbon reduction goals at appropriate stages.

Energy Performance Evaluation

By analyzing energy consumption data of various equipment, production lines, workshops, and teams, it provides data support for operational decisions and financing decisions.

Energy Early Warning and Control

Real-time monitor power quality issues, timely detect abnormal energy consumption, and prevent energy waste through control measures.

-

Industrial GateWay

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.

click to view detail>>

-

IOT Terminals

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.

click to view detail>>

-

Industrial Router

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.

click to view detail>>

-

NAT Coupler

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.

click to view detail>>

-

Software Platforms

click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>> WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>>

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>> WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>>

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>> The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>>

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>>

Go Top

Go Top