Construction Machinery

Improve Equipment Management Efficiency and Enhance Customer Satisfaction

Real-time Monitoring

Fault Early Warning

Remote Maintenance

Operation and Maintenance Management

Remote Control

Data Analysis

Construction machinery comes in a wide variety and is widely distributed. Traditional equipment management methods are inefficient and make it difficult to monitor equipment status and location in real time. Equipment failures can cause delays in construction progress and increase project costs. To enhance the management efficiency of construction machinery and ensure smooth project execution, a remote monitoring solution is required.

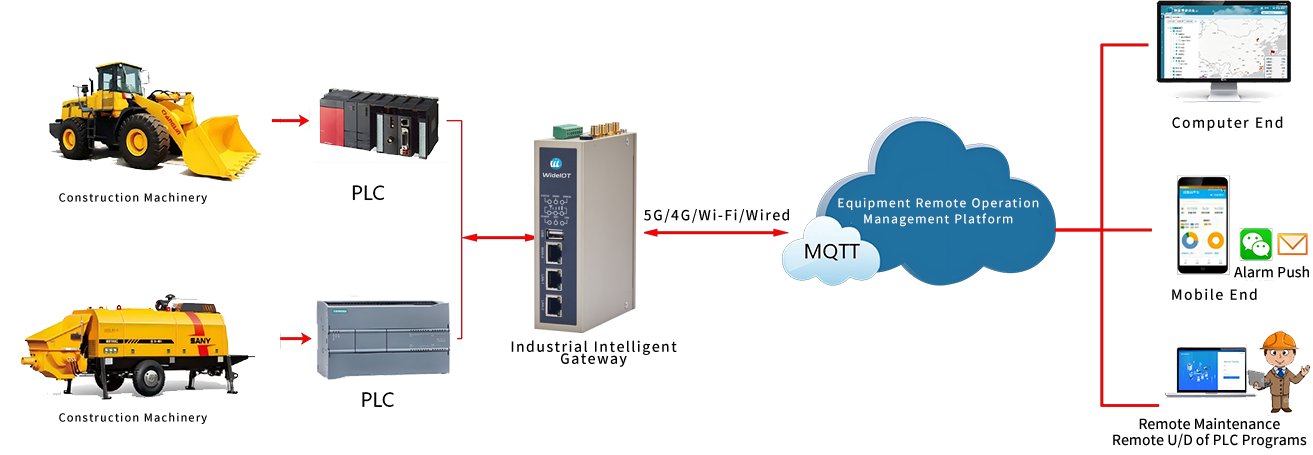

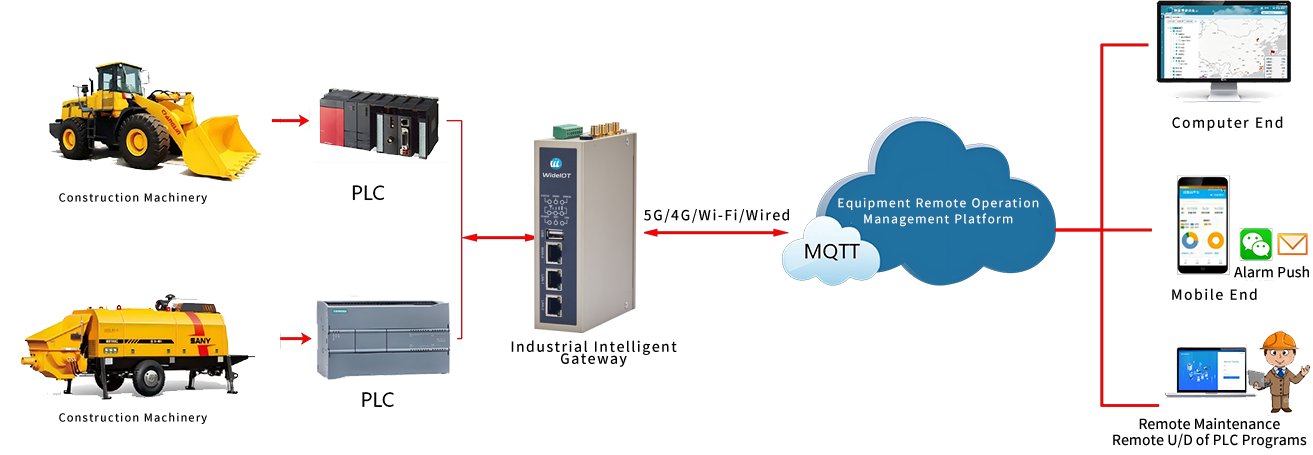

Through WideIOT's industrial smart gateway, controllers, sensors, and other devices in construction machinery are connected to collect real-time data including equipment location, operational status (such as active, idle, or malfunction), operating parameters (like engine RPM, oil pressure, coolant temperature), and fuel consumption. This collected data is transmitted to the equipment operation and maintenance management platform for analysis and processing. When equipment malfunctions occur, timely alerts are issued. Remote maintenance is performed via WideIOT's Equipment Maintenance Express, enhancing maintenance efficiency, reducing operational costs, and enabling comprehensive digital management throughout the equipment's entire lifecycle.

Real-time Monitoring

Collect data such as equipment location, rotational speed, and fuel consumption, display it in real time on the platform, and send immediate alerts for abnormal statuses. Help manufacturers keep track of equipment dynamics at all times and avoid information delay.

Fault Early Warning

Based on preset thresholds and data analysis, identify potential equipment faults in advance and promptly notify operation and maintenance engineers. Improve maintenance efficiency, reduce unplanned downtime, and ensure the steady progress of projects.

Remote Maintenance

In case of equipment failure, engineers can perform remote debugging of the equipment's PLC and remote upload/download of programs through the remote maintenance channel, reducing operation and maintenance costs.

Operation and Maintenance Management

Online creation and assignment of maintenance work orders, tracking of work order progress, recording of operation and maintenance history, and visualization of the operation and maintenance process. Improve the efficiency and standardization level of after-sales services.

Remote Control

Under safety authorization, remotely execute operations such as equipment fuel cut-off and start-stop to respond to emergencies like equipment abnormalities and ensure asset safety.

Data Analysis

Conduct in-depth mining of equipment operation data to generate decision-making reports for maintenance, procurement, etc. Provide data support for manufacturers to optimize product design and adjust operation and maintenance strategies.

-

Industrial GateWay

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.

click to view detail>>

-

IOT Terminals

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.

click to view detail>>

-

Industrial Router

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.

click to view detail>>

-

NAT Coupler

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.

click to view detail>>

-

Software Platforms

click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>> WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>>

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>> WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>>

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>> The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>>

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>>

Go Top

Go Top