Remote Monitoring for Charging Piles

Optimize EV Charging Pile Operation and Enhance Charging Services

EV Charging Pile Status Monitoring

Charging Data Statistics

Fault Early Warning and Handling

Remote Parameter Configuration

Remote Device Management

Operational Data Analysis

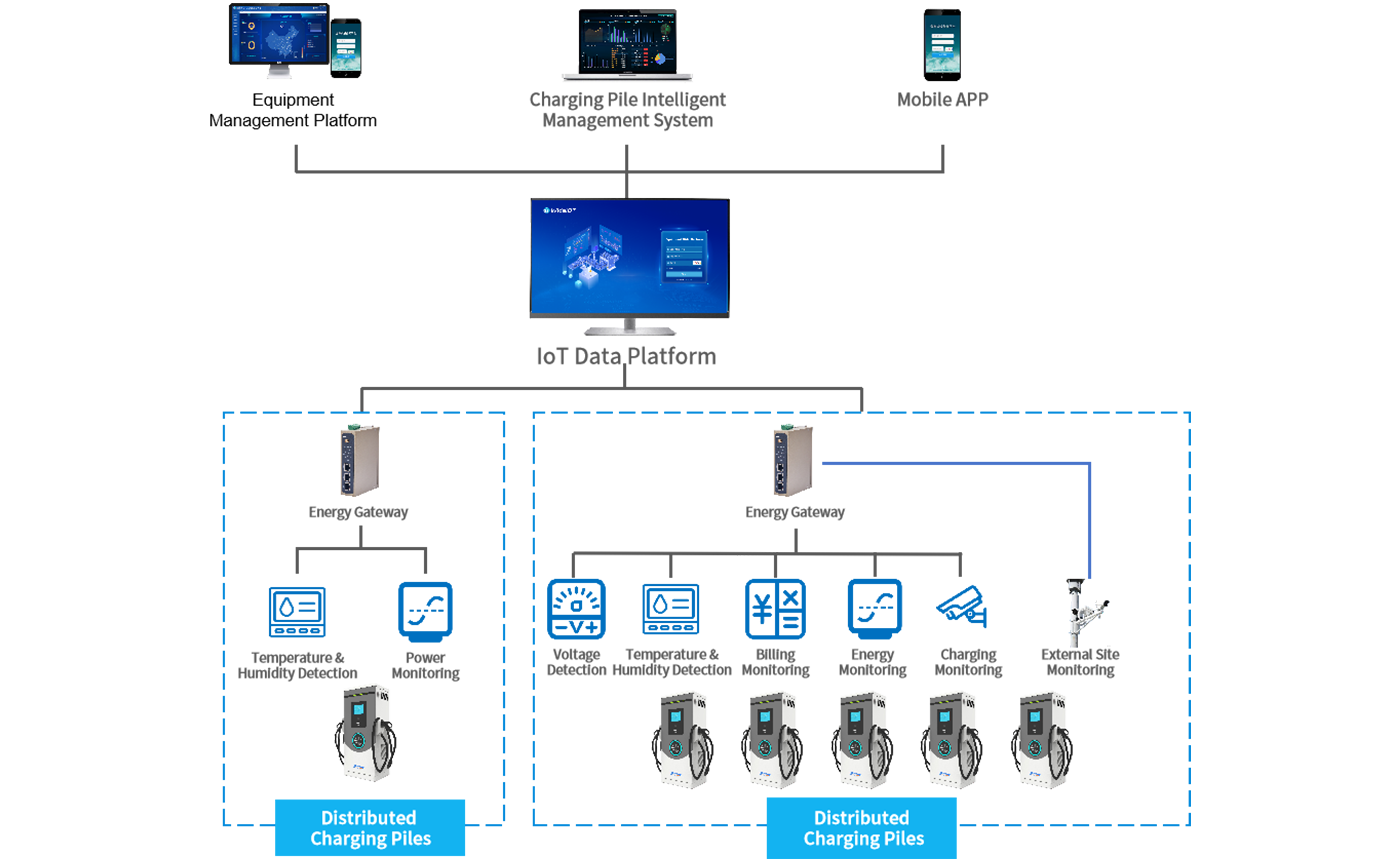

With the popularization of electric vehicles, the number of charging piles is constantly increasing. Charging piles are widely and dispersedly distributed, making it difficult for traditional management methods to conduct real-time monitoring and effective maintenance of them. Charging pile faults may prevent users from charging normally and affect user experience. To improve the operational efficiency of charging piles, ensure the quality of charging services, and reduce operation and maintenance costs, a remote monitoring and management system is required.

Via WideIOT's industrial intelligent gateways, the operation data of charging piles (such as charging status, voltage, current, and fault information) is collected and transmitted in real time to the charging pile remote monitoring and management platform. The platform monitors the status of charging piles and counts charging data; when a charging pile malfunctions, it issues an early warning in a timely manner and provides fault handling guidance. It also supports functions such as remote parameter configuration, user service management, and operation data analysis.

EV Charging Pile Status Monitoring

Real-time grasp the operating status of charging piles to ensure stable charging services.

Charging Data Statistics

Count data such as charging times and power volume to provide a basis for operational analysis.

Fault Early Warning and Handling

Timely detect and handle faults to reduce user waiting time.

Remote Parameter Configuration

Facilitate the adjustment of charging pile parameters and improve operational flexibility.

Remote Device Management

Remotely manage charging station sites and equipment to improve management efficiency.

Operational Data Analysis

Analyze operational data to optimize operational strategies and cost control.

-

Industrial GateWay

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.

click to view detail>>

-

IOT Terminals

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.

click to view detail>>

-

Industrial Router

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.

click to view detail>>

-

NAT Coupler

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.

click to view detail>>

-

Software Platforms

click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>>

WideIOT · WG series industrial intelligent gateway is a high reliability industrial intelligent gateway that supports the collection of data of various industrial equipment such as PLC, instrument, water environmental protection, power equipment, CNC, and has protocol analysis and edge computing. It is the core edge node for building industrial Internet system.click to view detail>> WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>>

WideIOT·WD IOT Terminals mainly realizes the acquisition and control of digital DI, DO, analog AI, and AO of on-site industrial equipment, and realizes the functions of LORA local networking and 4G data cloud, so as to realize Data acquisition and control of field sensors, actuators, indicator lights, etc.click to view detail>> WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>>

WideIOT·WR series industrial wireless router is a network connection that supports 5G/4G/WIFI/Ethernet, etc., supports VPN networking, and provides low-latency, high-reliability, and high-security network access for field devices. input, so as to realize large-scale equipment networking applications.click to view detail>> The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>>

The WideIOT NAT Coupler is a specialized security isolation device for production networks. It supports IP renaming for unified IP planning, enables cross-segment device access via network segmentation, and effectively mitigates same-segment conflicts and broadcast storms. It is ideal for industrial networks demanding high data reliability, including those with PLCs, HMIs, CNCs, DCSs, and MES.click to view detail>>

Go Top

Go Top