-

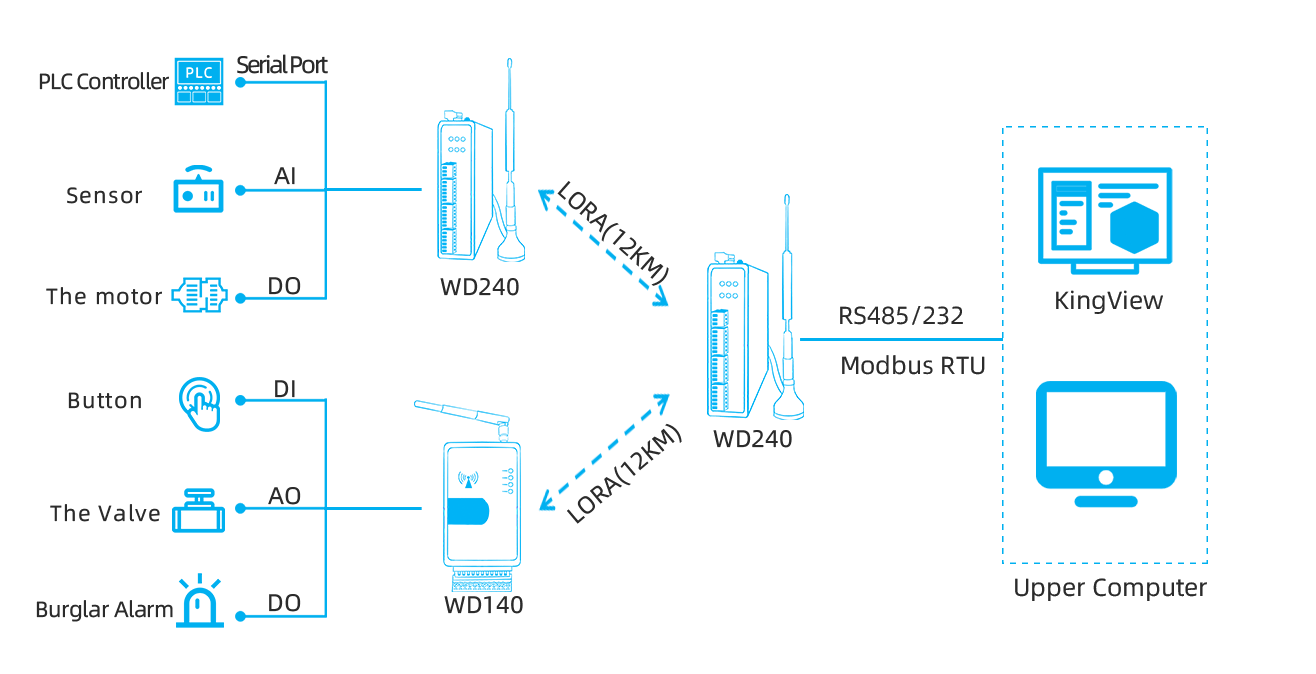

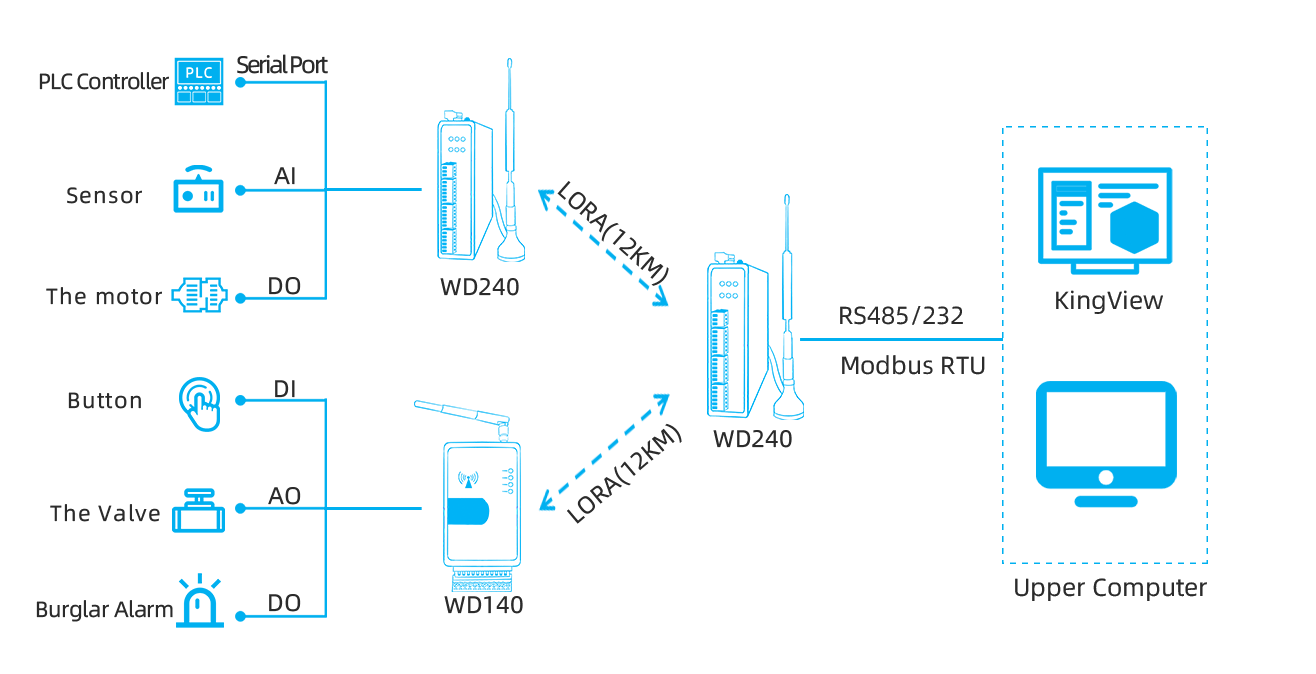

IO Data Acquisition Terminal Access to Modbus IoT System

2025-12-02 11:01:04

In industrial automation control systems, IO data acquisition terminals can connect to on-site equipment (such as PLCs, sensors, CNC machines, industrial robots, etc.) to collect various types of data, including digital input (DI), digital output (DO), analog input (AI), and analog output (AO), thereby enabling real-time monitoring and intelligent management of production processes.

WideIOT's IO data acquisition terminal is an industrial-grade Modbus I/O data acquisition, LORA data transmission, and 4G data cloud upload industrial smart terminal.

It supports LORA wireless transmission, 4G data cloud upload, multi-channel IO data acquisition, Modbus RTU protocol, and wireless 485 transmission. The terminal offers multiple optional configurations for analog input, analog output, digital input, and digital output, facilitating rapid on-site data acquisition configuration.Application Scenarios

- The upper computer reads and controls the IO of the IO data acquisition terminal (lower computer) via a serial port.

- The upper computer reads the IO of the IO data acquisition terminal (lower computer) via LORA wireless.

- The upper computer reads the IO of the IO data acquisition terminal and the connected PLC data via LORA.

- The cloud platform reads the IO of the WD240 (presumably a model of the IO data acquisition terminal) and the connected PLC data via LORA wireless and the internet.

Achieved Functions- Remote Monitoring and Control: Users can remotely monitor and control the IO data acquisition terminal and the lower computer in real-time, even from distant locations, enhancing system flexibility and convenience.

- Enhanced System Scalability: The IO data acquisition terminal features multiple interfaces and connection methods, allowing it to interface with various types of sensors and actuators. Users can select the optimal communication method based on actual needs.

- Reduced Maintenance Costs: Through the device maintenance express lane, users can perform remote programming debugging and remote program uploading and downloading, reducing the frequency and cost of on-site maintenance.

Go Top

Go Top