-

Printing Workshop Digital Monitoring and Management System Solution

2025-11-24 10:59:36

With the development of technology and the progress of society, the printing industry is continuously undergoing technological innovation and industrial upgrading.

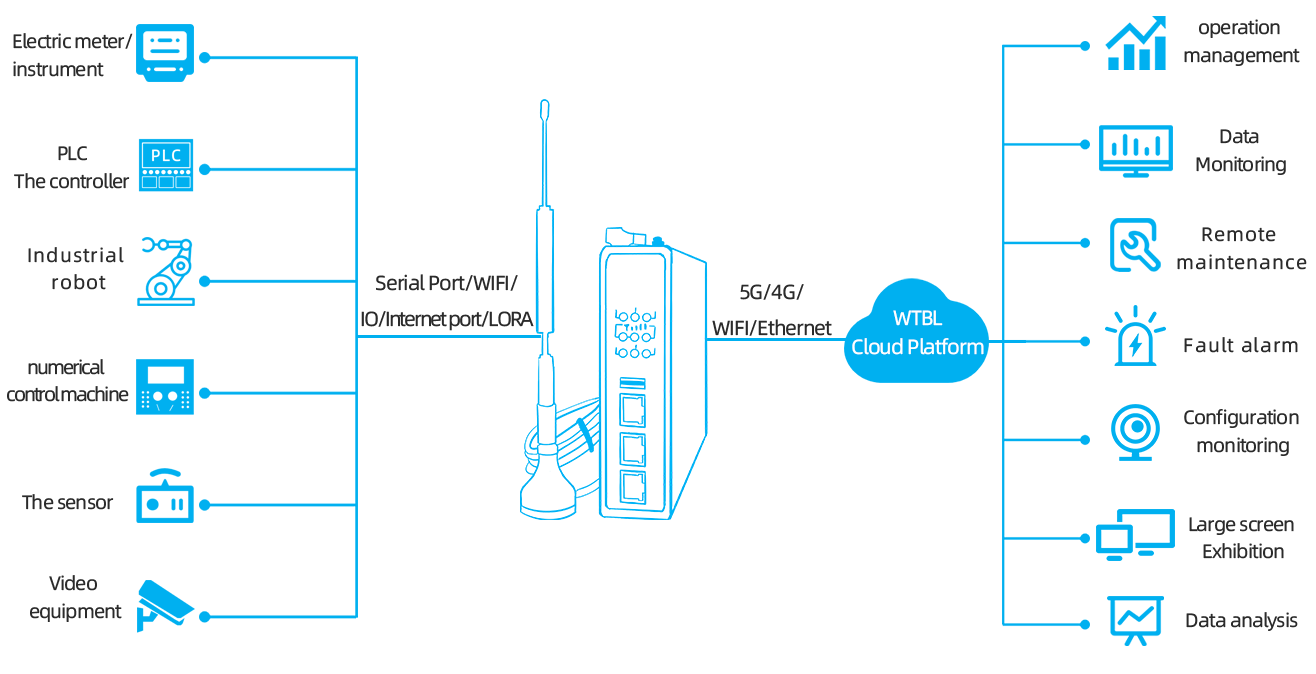

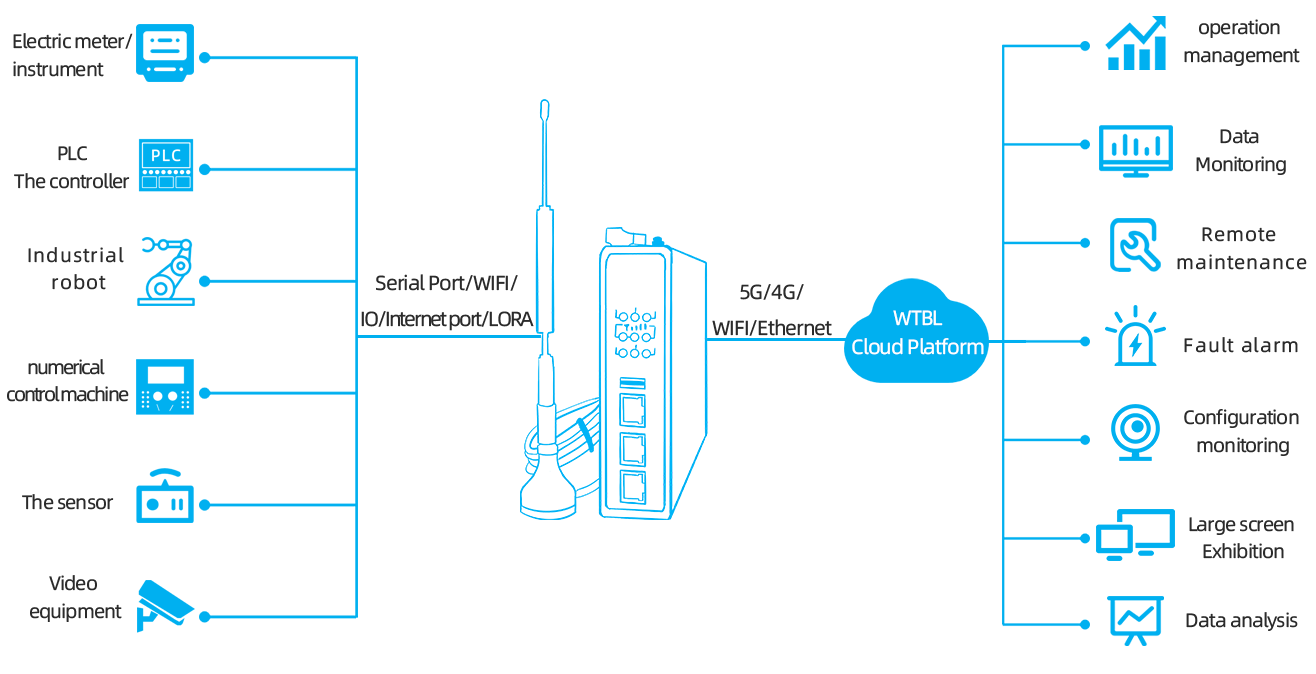

In this process, an important trend is the digitalization and intelligent transformation of printing workshops. To achieve this goal, a comprehensive digital monitoring and management system for printing workshops is required for support.WideIOT introduces a digital monitoring and management system solution for printing workshops based on industrial intelligent gateways.

This solution enables real-time monitoring of various aspects such as the operational status of printing equipment, product quality, and production efficiency. The gateway can connect to the PLCs of printing equipment for data collection and upload the data to cloud platforms or upper computers via 5G/4G/WIFI/Ethernet, thereby facilitating remote monitoring, fault预警 (fault warning), remote maintenance, data analysis, and other functions.

This data includes, but is not limited to, equipment operation status, equipment voltage and current, fault alarms, etc. Additionally, it can integrate with existing ERP/MES and other information systems to obtain more business data.

I. Data Collection

In the printing workshop, PLCs, sensors, and cameras of printing equipment are connected to the gateway for real-time data collection.II. Data Analysis

Furthermore, by summarizing historical data, future potential faults can be predicted to enable timely measures to be taken.

The collected data is deeply mined and analyzed using advanced algorithmic models to identify potential issues and find solutions.III. Visual Display

Additionally, it supports custom report export functionality for reporting to superiors or archiving purposes.

Data dashboards on mobile phones and computers are utilized to visually display trends and anomalies in various indicators, facilitating managers to promptly understand the current situation and take appropriate actions.IV. Intelligent Warning

Similarly, this can be applied to safety precautions such as fire alarms, significantly enhancing enterprise safety production levels.

When the system detects that a parameter exceeds the normal range, it automatically triggers a warning mechanism and notifies relevant personnel via SMS, email, WeChat, etc., to take corresponding measures to prevent losses from expanding.V. Remote Maintenance

Engineers can access remote PLCs at any time without being on-site, performing PLC remote programming, debugging, and uploading/downloading programs through device maintenance express lines, thereby improving work efficiency, reducing travel expenses, and swiftly restoring equipment faults and production order.

Go Top

Go Top