-

Air flotation packaging machine PLC data collection monitoring operation and maintenance system solution

2025-10-28 10:59:17

In the process of modern industrial automation, pneumatic floating packaging machines, as efficient and precise packaging equipment, have been widely applied in packaging fields such as food, chemicals, and building materials.

They achieve automatic bag clamping, automatic filling, intelligent weighing, automatic bag loosening, and automatic conveying, among other processes, offering advantages such as low dust levels, fast packaging speeds, and high efficiency.However, with the increasing demand for production efficiency, how to monitor and optimize the operational status of pneumatic floating packaging machines in real-time has become an urgent issue.

In response, WideIOT provides a solution based on PLC (Programmable Logic Controller) data acquisition, monitoring, and operation & maintenance system, aiming to enhance the intelligent management level of pneumatic floating packaging machines.

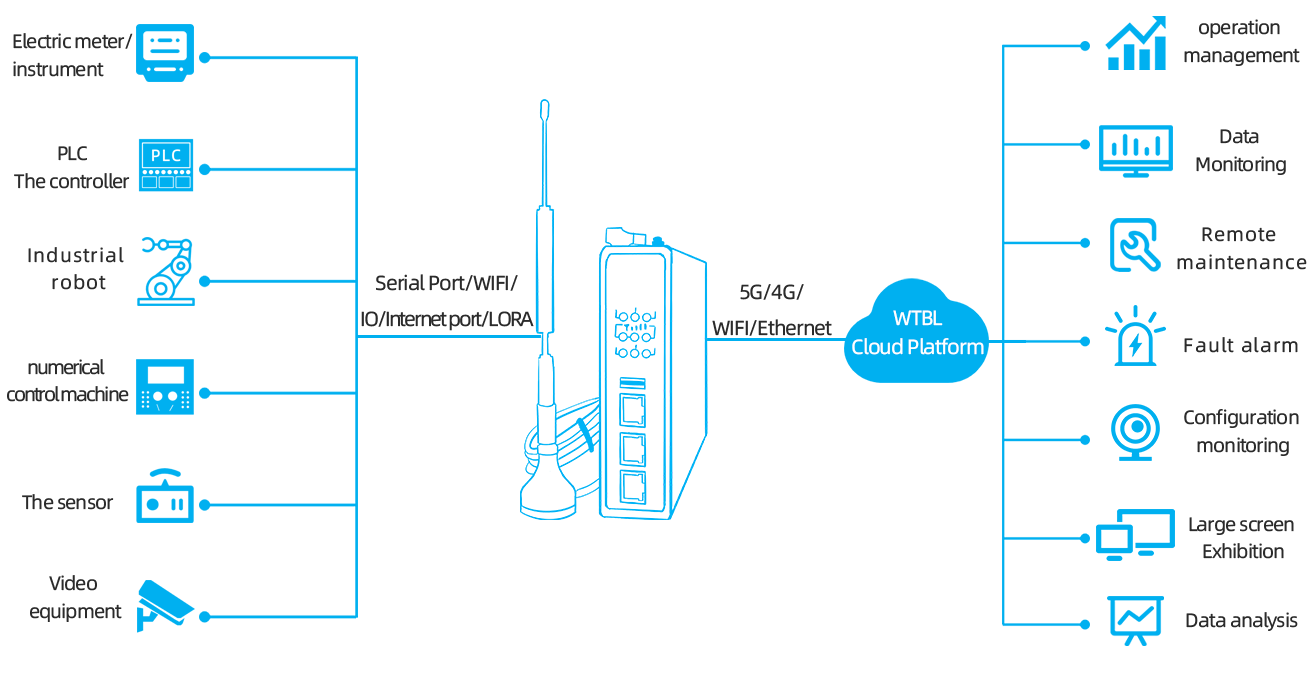

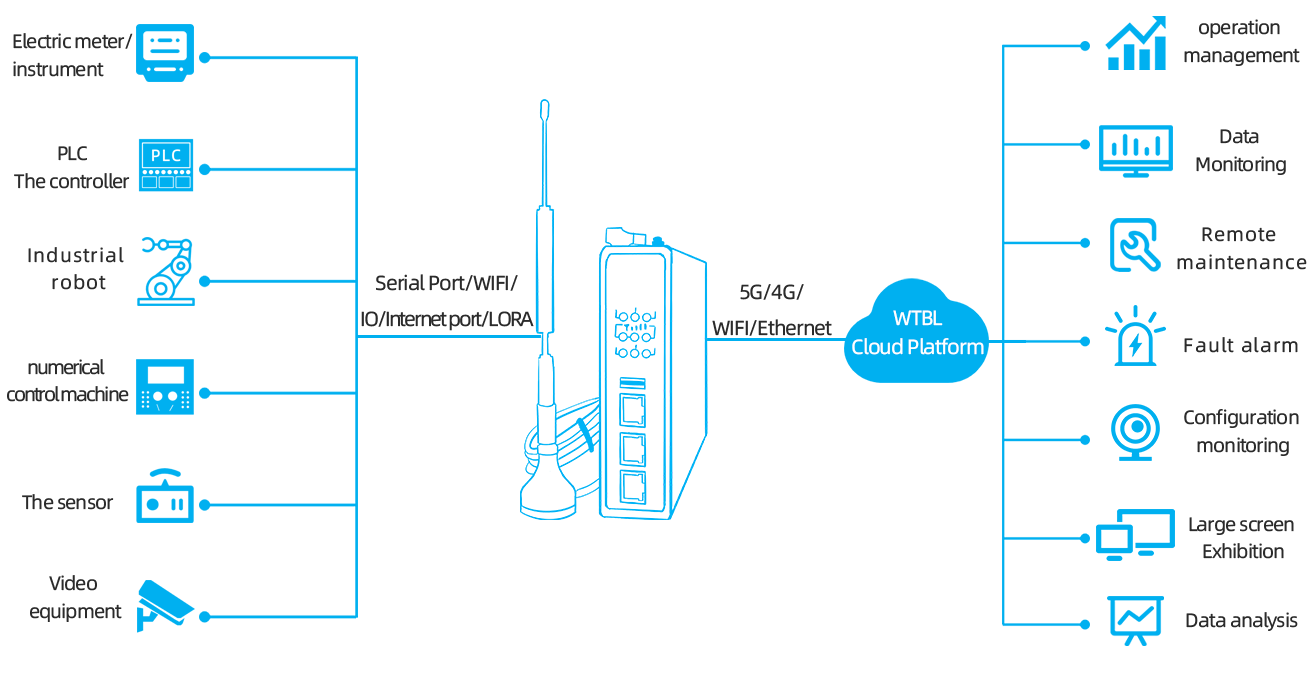

System OverviewThe core of this solution is to establish an IoT system integrating data acquisition, real-time monitoring, fault diagnosis, and remote operation & maintenance, based on WideIOT PLC intelligent gateways.

This system not only enables precise monitoring and automatic alarms for various parameters of the pneumatic floating packaging machine but also provides a scientific basis for decision-making through data analysis, thereby improving equipment stability and production efficiency.-

Data Acquisition Module

The WideIOT PLC intelligent gateway can connect to the PLC of the pneumatic floating packaging machine for protocol parsing and data acquisition, allowing real-time acquisition of various operational parameters of the equipment, such as operational status, pneumatic pressure, and product weight. These data are processed through edge computing and then uploaded to a cloud database, providing rich data for subsequent analysis.

The foundation of the IoT system is the data acquisition module. -

Real-time Monitoring Function

Utilizing the gateway for 5G/4G internet access, operators can intuitively understand the working status and process parameters of the pneumatic floating packaging machine through a visual interface. In case of any abnormalities, the system automatically issues alarms and notifies relevant personnel via WeChat, SMS, or email, enabling timely measures to be taken to reduce downtime losses.

Remote and real-time monitoring functions are crucial for ensuring the smooth operation of the equipment. -

Data Analysis Function

With big data analysis technology, managers can not only quickly locate problems after failures occur but also perform trend analysis based on historical data to preemptively warn of potential risk points, forming predictive maintenance strategies. This significantly reduces the probability of sudden equipment failures and improves production continuity.

Data analysis is an important means of supporting predictive maintenance. -

Remote Operation & Maintenance Support

The online operation & maintenance model enables the operation & maintenance team to have a comprehensive understanding of the on-site situation even when they are located remotely. Through the WideIOT device maintenance express line, technicians can remotely access the PLC control system for remote programming, debugging, and uploading/downloading programs. This not only saves manpower and material resources but also greatly enhances the speed and quality of problem response.

-

Go Top

Go Top